Domestication method for microorganisms for performing purification treatment on cold-rolling organic wastewater

A technology for purification and treatment of organic wastewater, applied in the direction of using microbial methods, chemical instruments and methods, and aerobic process treatment, can solve the problems of cold rolling wastewater volume and wastewater composition fluctuations, effluent not up to standard, and complex components, etc. Achieve the effect of avoiding dormancy and death and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

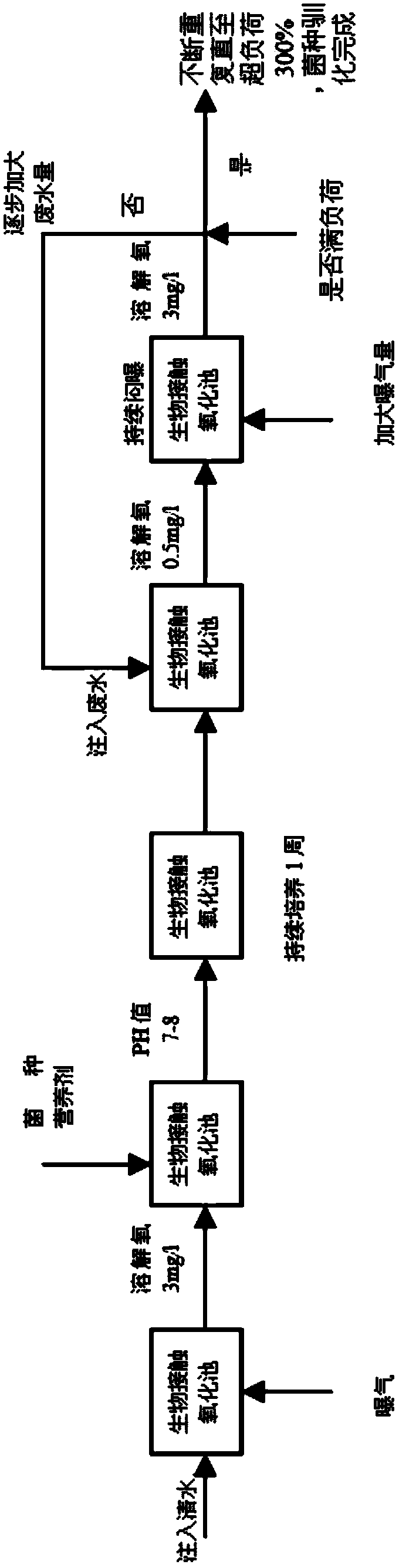

[0021] see figure 1 , a method for acclimating microorganisms used to purify and treat cold-rolled organic wastewater provided by an embodiment of the present invention, comprising:

[0022] Step S1: Fill the biological contact oxidation tank with clean water, turn on the aeration, add bacteria and nutrients, and control the dissolved oxygen at about 2.5-3.5mg / L; when the biological contact oxidation tank is filled with clean water, the pH value Control it at 7-8, and control the water temperature at 18-25°C. The strains added when domesticating aerobic microorganisms are active biological strains, the main component of which is a biological complex bacterial liquid. The strains include aerobic bacteria, including Bacillus lipolytica, Pseudomonas, Saccharomyces cerevisiae, Micrococcus, Rhodococcus, and Brevibacterium, the bacteria content is 108-109 / mg, and the dosage is 0.05% of the effective volume (volume occupied by the actual solution) in the biological contact oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com