A kind of iron-based soft magnetic composite magnetic powder core and preparation method thereof

A soft magnetic composite and magnetic powder core technology, which is applied in the direction of magnetic materials, magnetic objects, and inorganic materials, can solve the problems of poor insulation, poor thermal stability, and low saturation magnetic induction of magnetic powder cores, and achieve high saturation magnetic induction and thermal stability. Good stability and low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

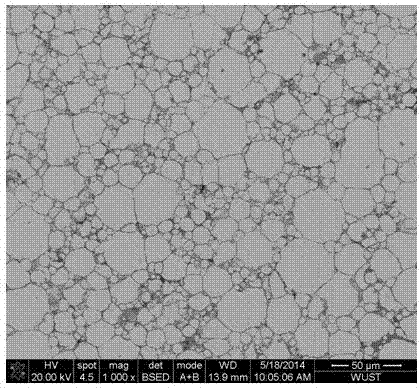

Image

Examples

Embodiment 1

[0035] An iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0036] The first step, surface modification of iron-based alloy powder

[0037] According to the mass ratio of iron-based alloy powder powder: absolute ethanol: silane coupling agent: distilled water is 1: (6-7): (0.04-0.05): (0.20-0.25), the iron-based alloy powder, absolute ethanol , silane coupling agent and distilled water are sequentially added into the reaction vessel, and stirred at 40-45° C. for 1.5-2.0 hours to obtain a mixed solution containing surface-modified iron-based alloy powder.

[0038] The second step, preparation of core-shell heterostructure composite powder

[0039] Under stirring conditions at 40-45°C, firstly add ethyl orthosilicate to the mixed solution containing surface-modified iron-based alloy powder, then add ammonia water, and continue stirring for 8-10 hours; then u...

Embodiment 2

[0053] An iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0054] The first step, surface modification of iron-based alloy powder

[0055] According to the mass ratio of iron-based alloy powder: absolute ethanol: silane coupling agent: distilled water is 1: (7-8): (0.05-0.06): (0.25-0.30), the iron-based alloy powder, absolute ethanol, The silane coupling agent and distilled water are sequentially added into the reaction container, and stirred at 45-50° C. for 2.5-3.0 hours to obtain a mixed solution containing surface-modified iron-based alloy powder.

[0056] The second step, preparation of core-shell heterostructure composite powder

[0057] Under stirring conditions at 45-50°C, first add methyl orthosilicate to the mixed solution containing surface-modified iron-based alloy powder, then add ammonia water, and continue stirring for 10-12 hours; then us...

Embodiment 3

[0071] An iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0072] The first step, surface modification of iron-based alloy powder

[0073] According to the mass ratio of iron-based alloy powder: absolute ethanol: silane coupling agent: distilled water is 1: (8-9): (0.06-0.07): (0.30-0.35), iron-based alloy powder, absolute ethanol, The silane coupling agent and distilled water are sequentially added into the reaction vessel, and stirred at 50-55° C. for 1.0-1.5 hours to obtain a mixed solution containing surface-modified iron-based alloy powder.

[0074] The second step, preparation of core-shell heterostructure composite powder

[0075] Under stirring conditions at 50-55°C, firstly add ethyl orthosilicate to the mixed solution containing surface-modified iron-based alloy powder, then add ammonia water, and continue stirring for 12-14 hours; then use abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com