A kind of production equipment of graphene heat sink and production process of graphene heat sink with controllable thickness

A production process and production equipment technology, applied in the field of graphene heat sink production process, can solve the problems of high process, time-consuming, low production capacity, etc., and achieve the effects of low preparation temperature, reduced production cost, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

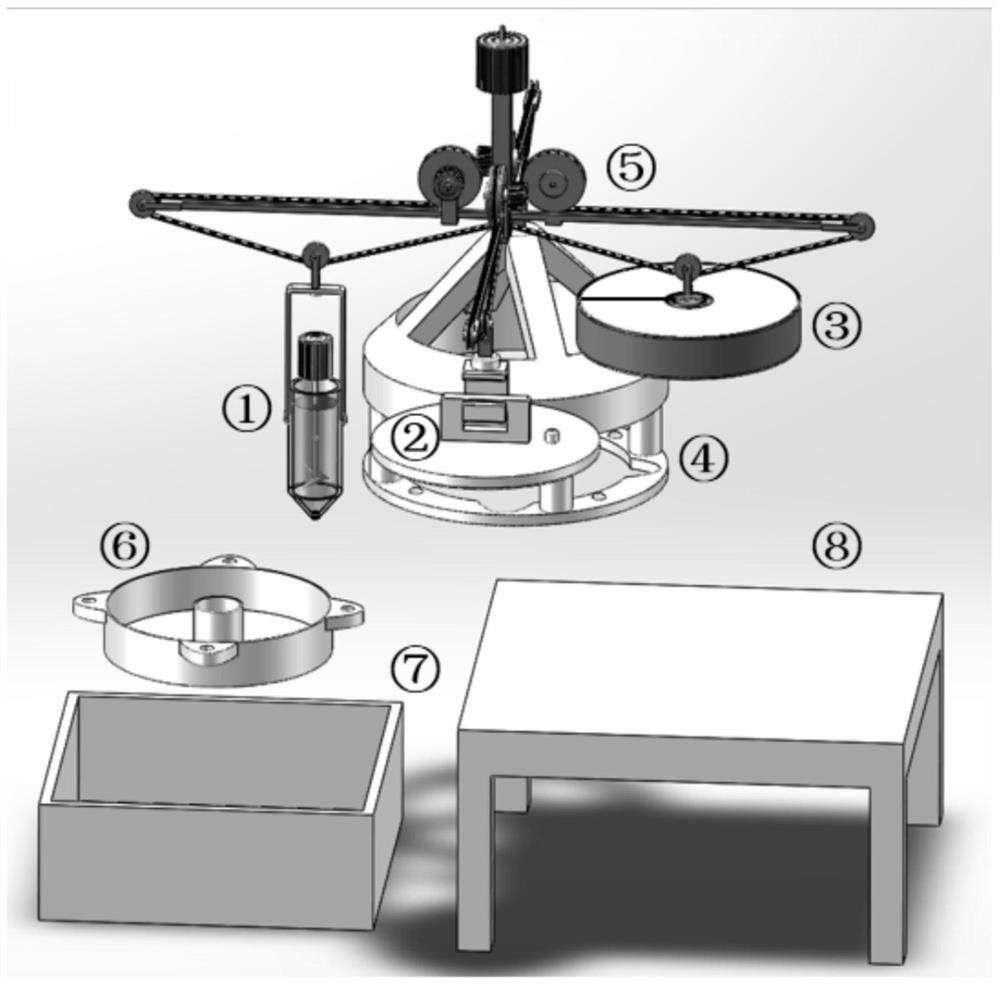

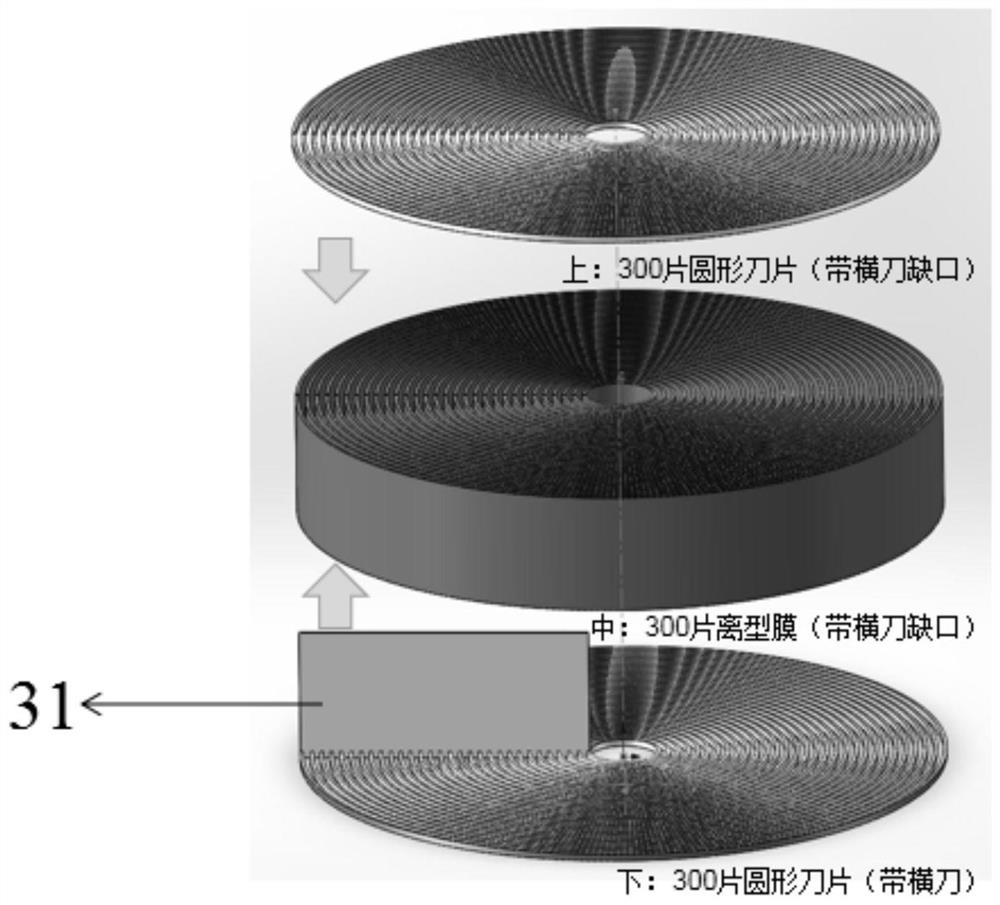

[0039] The present embodiment provides a production equipment for a graphene heat sink, refer to figure 1 , figure 2 , including stirring kettle 1, gland 2, slitting die 3, disc storage bucket hook 4, cross steel shaft 5, disc storage bucket 6, heating device 7 and workbench 8;

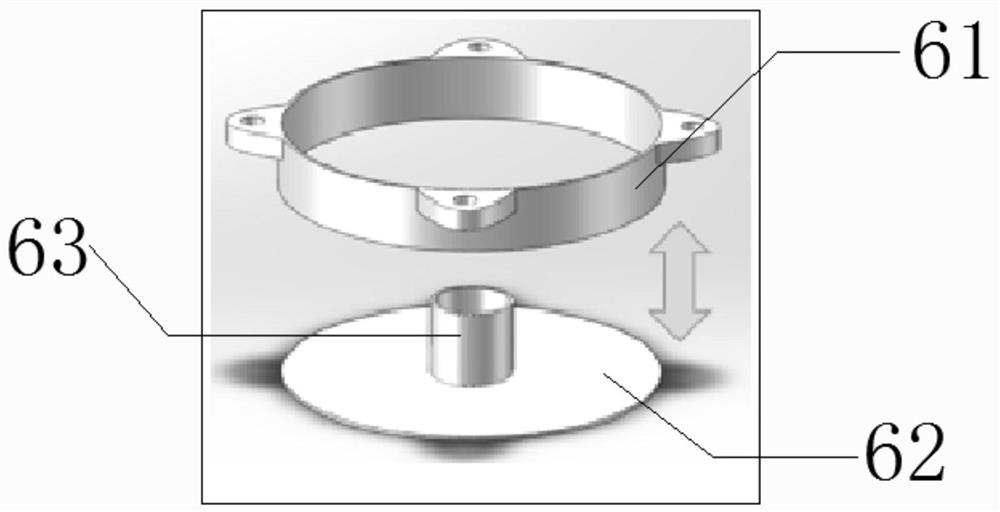

[0040] Among them, the stirring kettle 1, the gland 2, the slitting die 3, and the hook 4 of the disc type storage bucket are respectively installed in the four directions of the cross steel shaft 5; the disc type storage bucket 6 Including a barrel wall 61 and a base 62, the barrel wall 61 and the base 62 are detachably connected, the center of the base 62 is provided with a raised through hole 63, and the height of the raised through hole 63 is consistent with the height of the barrel wall 61; the The disc-type storage tank 6 is placed inside the heating device 7 .

Embodiment 2

[0042] The present embodiment provides a production process of a graphene heat sink with controllable thickness, comprising the following steps:

[0043] (S1) Graphene slurry, epoxy resin and polyethylene glycol with a monolayer ratio of 60% and a solid content of 1 wt.% are prepared to obtain a mixed slurry;

[0044] (S2) the described mixed slurry is injected into the double-spiral stirred tank 1 with a volume of 50 L, after stirring and auxiliary defoaming, an infusion pump is provided at the bottom of the double-spiral stirred tank 1, and the mixed slurry is injected into the disc by the infusion pump Type storage tank 6, the disc type storage tank 6 is made of 310S stainless steel, with an inner diameter of 1000mm and a height of 200mm. The diameter of the raised through hole 63 is 200mm and the height is 200mm; the slurry to be mixed is injected into the disk When the height of the storage tank 6 is 180mm, the cross steel shaft 5 is rotated by the controller to seal the ...

Embodiment 3

[0050] The present embodiment provides a production process of a graphene heat sink with controllable thickness, and the difference from Embodiment 2 is:

[0051] In step (S1), a graphene slurry with a monolayer ratio of 99% and a solid content of 10wt.%, a phenolic resin and sodium dodecyl sulfate are prepared to obtain a mixed slurry;

[0052] In step (S2), the volume of double-spiral stirred tank 1 is 60L, and the weight of gland 2 is 600kg;

[0053] In step (S3), at a rate of 10°C / min, the temperature of the heating device is increased from 7 to 1200°C, and the mixed slurry is sintered at this temperature for 60 minutes, and is naturally cooled to room temperature after completion.

[0054] The other operations were the same as those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com