A solid electrolytic capacitor based on graphene composite polyaniline

A graphene composite, solid-state electrolysis technology, applied in solid electrolytic capacitors, capacitor parts, capacitor electrolytes/absorbents, etc., can solve the problems of reducing capacitor performance, increasing internal resistance, etc., to improve stability, equivalent series Low resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

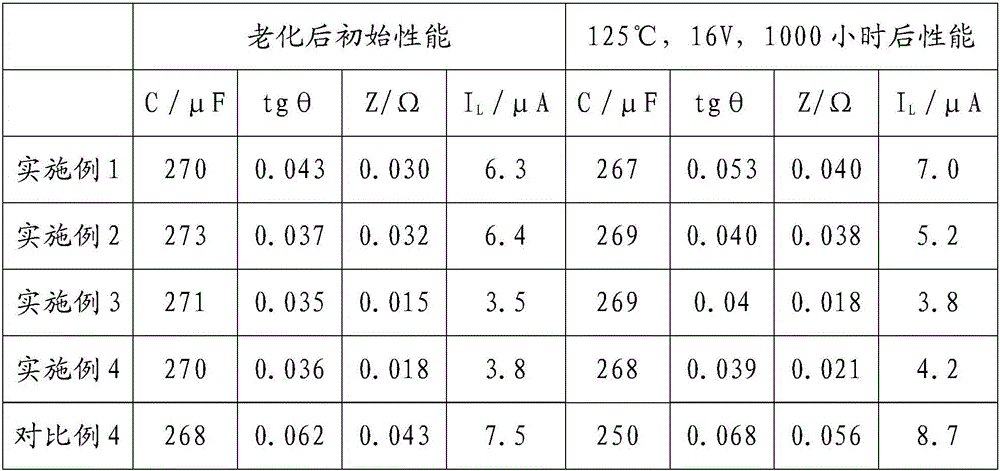

Examples

Embodiment 1

[0033] Insert the separator between the anode foil and the cathode foil, and wind it into a core package, immerse it in the chemical conversion solution composed of phosphoric acid, and apply a voltage of 19.2V at 15°C (the repair temperature is 60°C-95°C) for chemical conversion repair. And carry out carbonization, cleaning and drying treatment. Dissolve 4.66g of graphite oxide in 500mL of water, ultrasonicate for 2 hours to obtain a stable brown graphene oxide aqueous solution, add 46.6g of aniline monomer (mass ratio of graphite oxide to aniline is 1:10), then add 147g of phosphoric acid, and ultrasonically stir for half After one hour, set the volume to 1000ml to obtain a graphene oxide / aniline dispersion, which is divided into two parts on average, one part is dispersion A; 2.5g ammonium persulfate is added in the other part to obtain dispersion B; The core bag was immersed in the dispersion A for 0.5 hours, a 3V DC voltage was applied between the anode and the cathode of...

Embodiment 2

[0035]Insert a separator between the anode foil and the cathode foil, and wind it into a core package, immerse it in a chemical solution composed of phosphoric acid, apply a voltage of 19.2V at 15°C for chemical conversion repair, and perform carbonization, cleaning, and drying treatments. Dissolve 23.3g of graphite oxide in 500mL of water, and ultrasonicate for 2 hours to obtain a stable brown graphene oxide aqueous solution. After adding 46.6g of aniline monomer (mass ratio of graphite oxide to aniline is 1:2), add 441g of phosphoric acid, and ultrasonically stir for half After one hour, set the volume to 1000ml to obtain a graphene oxide / aniline dispersion, which is divided into two parts on average, one part is dispersion A; 2.5g ammonium persulfate is added in the other part to obtain dispersion B; The core package was immersed in the dispersion A for 2 hours, a 5V DC voltage was applied between the anode and the cathode of the electrolytic capacitor, and electrochemical p...

Embodiment 3

[0037] Insert a separator between the anode foil and the cathode foil, and wind it into a core package, immerse it in a chemical solution composed of phosphoric acid, apply a voltage of 19.2V at 15°C for chemical conversion repair, and perform carbonization, cleaning, and drying treatments. Dissolve 14g of graphite oxide in 500mL of water, and ultrasonicate for 2 hours to obtain a stable brown graphene oxide aqueous solution. After adding 46.6g of aniline monomer (mass ratio of graphite oxide to aniline is 3:10), add 147g of phosphoric acid, and ultrasonically stir for half an hour. hour, set the volume to 1000ml, and obtain the graphene oxide / aniline dispersion liquid, which is divided into two parts on average, one part is the dispersion liquid A liquid; 2.5g ammonium persulfate is added to the other part to obtain the dispersion liquid B liquid; The core package was immersed in dispersion A for 0.5 hours, a 3V DC voltage was applied between the anode and cathode of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com