Copper bump package interconnection structure and method filled with double-layer underfill glue

An interconnection structure and double-bottom technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of unsatisfactory reliability of copper bumps and the inability to reduce stress at the chip end, and improve electrical connection characteristics and effects of mechanical stability, stress reduction, and high electrical connection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to fully demonstrate the advantages and positive effects of the present invention, the substantive features and remarkable progress of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

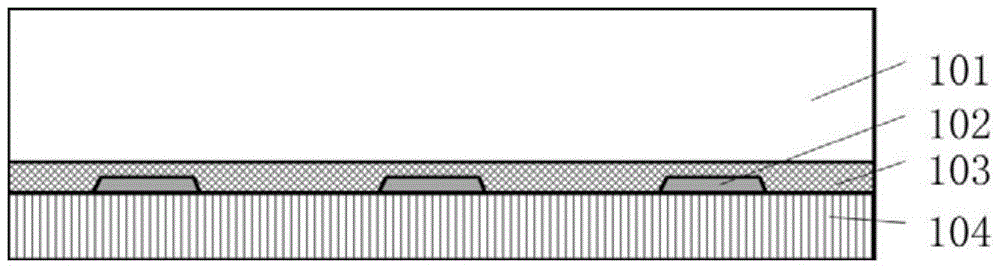

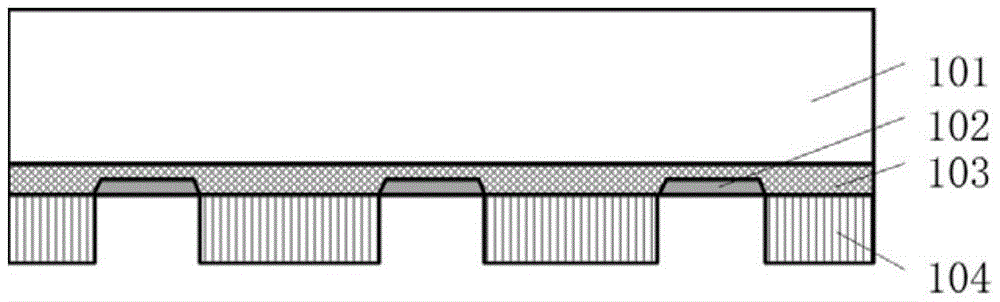

[0052] figure 1 On the active surface of the chip, a layer of thicker photoresist 104 is coated, wherein the pitch of the bumps is 120 μm, the diameter of the UBM opening is about 60 μm, and the thickness of the photoresist is about 30 μm.

[0053] figure 2 It is exposed at the position corresponding to the UBM, and the UBM is exposed at the corresponding position after development.

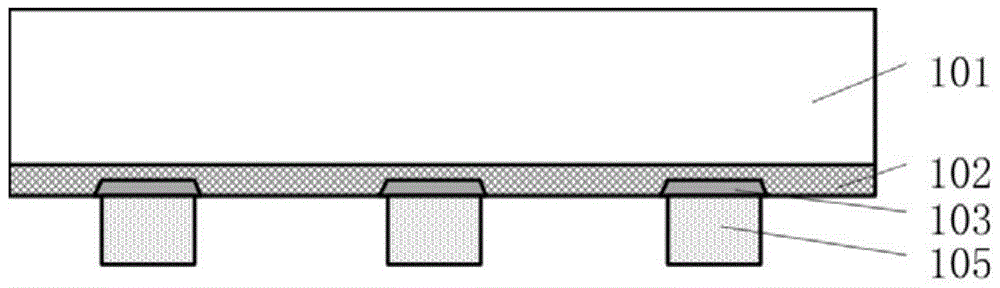

[0054] image 3 It is a schematic diagram of the copper bump shape formed by sputtering a seed layer at the copper bump position, followed by electroplating and glue removal. The copper bumps are 60 μm in diameter and 30 μm high.

[0055] Figure 4 After the copper bumps are plated, the first layer of underfill glue is spin-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com