Method for preparing iron phosphide and carbon composite structure by utilizing carbothermic reaction

A carbothermal reaction and iron phosphide technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as high cost, high chemical activity, and high price, and achieve easy operation, The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] FeCl 3 .6H 2 O, NH 4 h 2 PO 4 and C 3 N 6 h 6 The masses are 0.1g, 0.0213g and 4g respectively, FeCl 3 .6H 2 O and NH 4 h 2 PO 4 Dissolve in 1.2mL deionized water, drop into C by dipping method 3 N 6 h 6 , after drying, at N 2 (Flow rate 100sccm) at 3°C / min to 800°C, keep warm for 30min and then cool naturally.

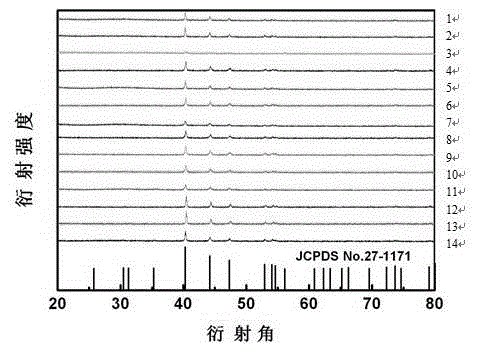

[0025] X-ray diffraction (XRD) showed that the obtained product was pure Fe 2 P crystal phase.

Embodiment 2

[0027] FeCl 3 .6H 2 O, NH 4 h 2 PO 4 and C 3 N 6 h 6 The masses are 0.5g, 0.1065g and 4g respectively, FeCl 3 .6H 2 O and NH 4 h 2 PO 4 Dissolve in 1.2mL, drop into C by dipping method 3 N 6 h 6 , after drying, at N 2 (Flow rate 100sccm) at 3°C / min to 800°C, keep warm for 30min and then cool naturally.

[0028] X-ray diffraction (XRD) showed that the obtained product was pure Fe 2 P crystal phase.

Embodiment 3

[0030] The difference from Example 1 is:

[0031] FeCl 3 .6H 2 O, NH 4 h 2 PO 4 and C 3 N 6 h 6 The masses are 1g, 0.213g and 4g respectively, FeCl 3 .6H 2 O and NH 4 h 2 PO 4 Dissolve in 1.2mL, drop into C by dipping method 3 N 6 h 6 , after drying, at N 2 (Flow rate 100sccm) at 3°C / min to 800°C, keep warm for 30min and then cool naturally.

[0032] X-ray diffraction (XRD) showed that the obtained product was pure Fe 2 P crystal phase.

PUM

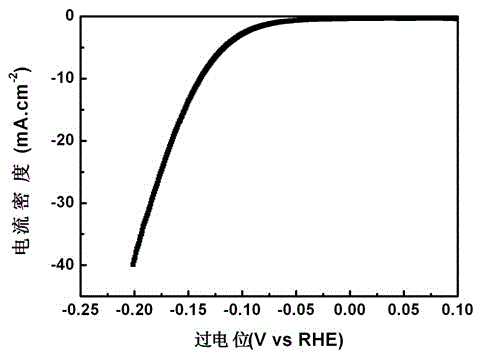

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com