Preparation method of wooden floor laying adhesive

An adhesive and floor technology, applied in the chemical industry, can solve the problems of unscientific and ideal use effect and small amount of existence, and achieve the effect of good use effect, easy operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

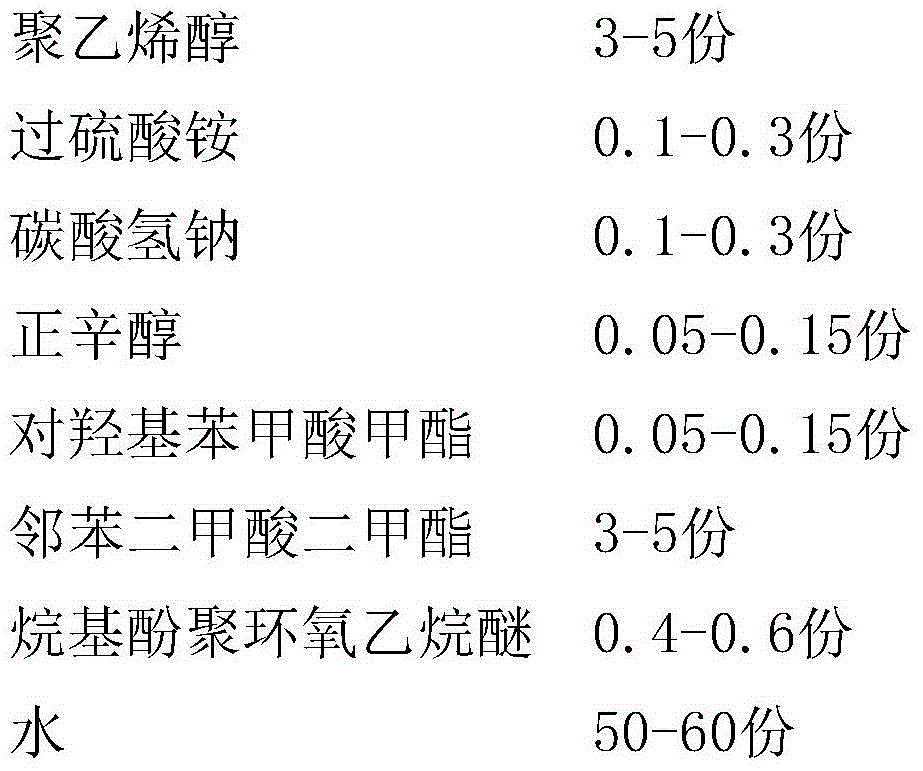

[0025] A wooden floor covering adhesive is composed of the raw materials of the following components:

[0026]

[0027]

[0028] Another object of the present invention is to prepare the method for wooden floor pavement adhesive of the present invention, comprising the following process steps,

[0029] a. choose a reaction kettle, and the described reaction kettle is equipped with a jacket and a stirrer.

[0030] b. Add the water in the raw materials into the reaction kettle selected in step a according to the formula amount, start to raise the temperature, and raise the water temperature in the kettle to 85-95°C.

[0031] c. Add all the polyvinyl alcohol in the raw material into the reaction kettle in step b according to the formula amount, and then add the alkylphenol polyethylene oxide ether, and stir and mix.

[0032] d. After the mixture in step c is stirred evenly, under the condition of constant stirring, ethyl acetate, butyl acrylate, and a 5% ammonium persulfat...

Embodiment 2

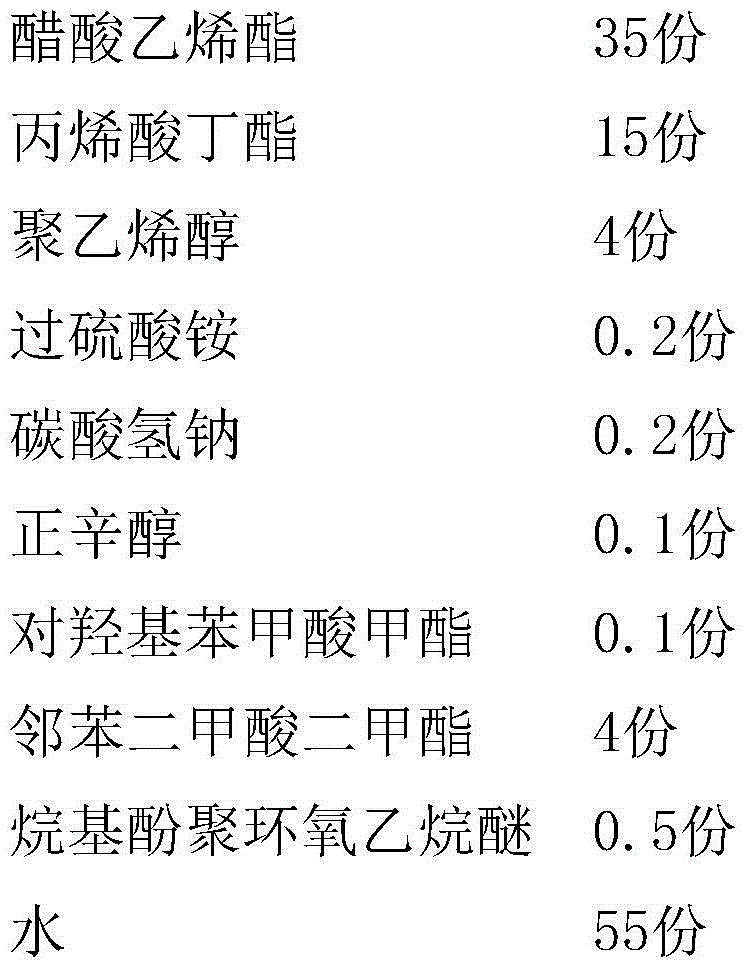

[0039] A wooden floor covering adhesive is composed of the raw materials of the following components:

[0040]

[0041]

[0042] Another object of the present invention is to prepare the method for wooden floor pavement adhesive of the present invention, comprising the following process steps,

[0043] a. choose a reaction kettle, and the described reaction kettle is equipped with a jacket and a stirrer.

[0044] b. Add the water in the raw materials into the reaction kettle selected in step a according to the formula amount, start to raise the temperature, and raise the water temperature in the kettle to 85-95°C.

[0045] c. Add all the polyvinyl alcohol in the raw material into the reaction kettle in step b according to the formula amount, and then add the alkylphenol polyethylene oxide ether, and stir and mix.

[0046] d. After the mixture in step c is stirred evenly, under the condition of constant stirring, ethyl acetate, butyl acrylate, and a 5% ammonium persulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com