Electromagnetic-radiation-resistant protection film and preparation method thereof

An anti-electromagnetic radiation, protective film technology, applied in the direction of film/sheet adhesive, adhesive type, polyurea/polyurethane adhesive, etc. Ideal and other problems to achieve the effect of improving conductivity, enhancing anti-electromagnetic radiation effect, and excellent anti-electromagnetic wave radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

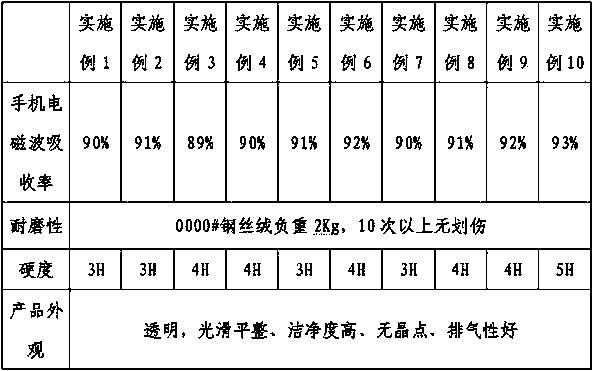

Examples

Embodiment 1

[0037] A preparation method for an anti-electromagnetic radiation protective film, comprising the following processing steps:

[0038] Step 1: Preparation of light-cured coating with anti-electromagnetic radiation function

[0039] A. Using multi-walled / single-walled carbon nanotubes, use 40 times the mass of concentrated nitric acid to heat and reflux in a boiling state. The heating temperature is 150°C. Purify and surface activate the carbon nanotubes. The reaction time is 5h, and then filter and use Washing with deionized water to obtain the treated carbon nanotubes;

[0040] B. Mix the treated carbon nanotubes and aniline under acidic conditions to form a prepolymer. The acidic conditions are to adjust the pH to 1 with HCl, and the mass ratio of carbon nanotubes to aniline is 1:50, and then add dropwise (NH 4 ) 2 S 2 o 8 undergoes oxidative polymerization, (NH 4 ) 2 S 2 o 8 The molar ratio to aniline is 1:1, and the carbon nanotube-polyaniline composite material is o...

Embodiment 2

[0049] The difference between this embodiment and Example 1 is: in this embodiment, step one, C, described light-cured coating also includes the graded nano-silver powder that is 1% by weight, and the graded nano-silver powder includes 200nm silver powder and The mass ratio of 30nm silver powder, 200nm silver powder and 30nm silver powder is 1:7.

[0050] The carbon nanotube-polyaniline composite material and graded nano-silver powder are dispersed into the acrylic polyurethane resin through high-speed stirring and ultrasonic dispersion equipment, and centrifugally filtered to obtain a photocurable coating with anti-electromagnetic wave effect. The carbon nanotube-polyaniline composite material accounts for The weight percentage of the light-cured coating is 3%, the weight percentage of the graded nano-silver powder accounts for the light-cured coating is 1%, and the weight percentage of the acrylic polyurethane resin accounts for the light-cured coating is 96%.

[0051] The r...

Embodiment 3

[0053] A preparation method for an anti-electromagnetic radiation protective film, comprising the following processing steps:

[0054] Step 1: Preparation of light-cured coating with anti-electromagnetic radiation function

[0055] A. Using multi-walled / single-walled carbon nanotubes, use 50 times the mass of concentrated nitric acid to heat and reflux in a boiling state. The heating temperature is 160°C. Purify and surface activate the carbon nanotubes. The reaction time is 4.5h, and then filter and washed with deionized water to obtain the treated carbon nanotubes;

[0056] B. Mix the treated carbon nanotubes and aniline under acidic conditions to form a prepolymer. The acidic conditions are to adjust the pH to 1 with HCl, and the mass ratio of carbon nanotubes to aniline is 1:60, and then add dropwise (NH 4 ) 2 S 2 o 8 undergoes oxidative polymerization, (NH 4 ) 2 S 2 o 8 The molar ratio to aniline is 1:1, and the carbon nanotube-polyaniline composite material is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com