A kind of lightweight high-conductivity shielding material and preparation method thereof

An electrical shielding and conductive filler technology, applied in the field of materials, can solve the problems of poor adhesion between conductive fillers and substrates, uneven distribution of conductive fillers, inconsistent conductivity of finished products, etc. The effect of wide and convenient molding and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

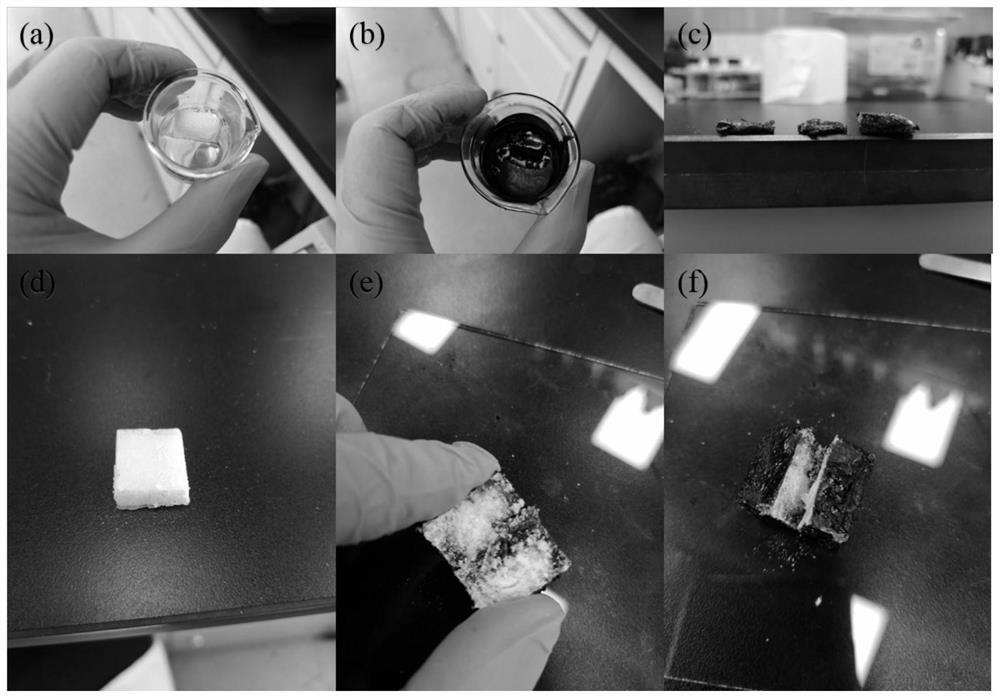

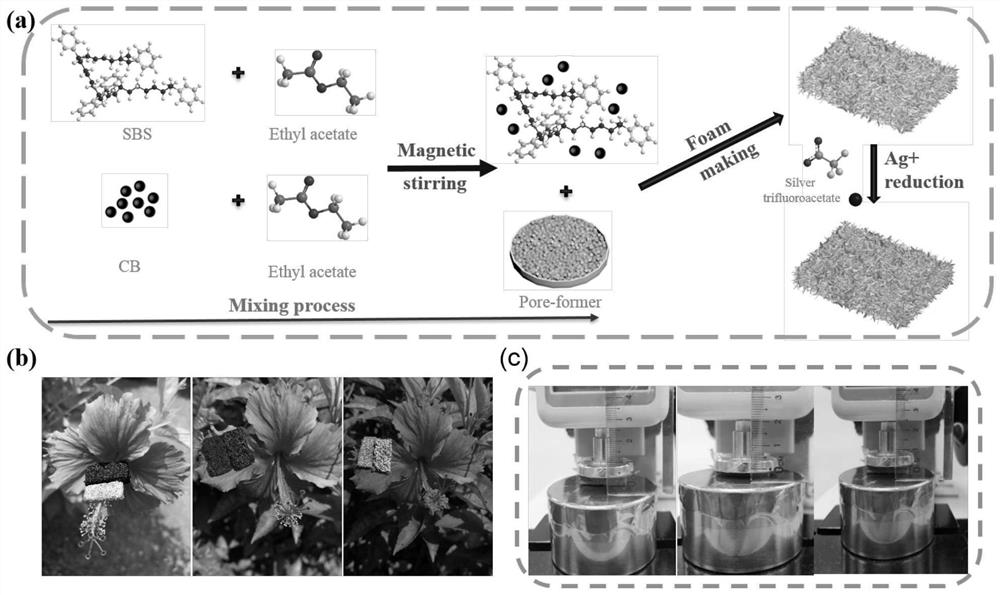

[0058] Embodiment 1 foam sample preparation experiment

[0059] Before the experiment, dry the polymer SBS to be used, and place it in an oven at 50-60°C for about 2 hours before use. In the experiment, ethyl acetate was used as the solvent of SBS, and a mixed solution of 20wt% SBS / ethyl acetate was prepared for use. At the same time, conductive filler particles carbon black (CB) were used as carbon-based fillers, and CB was dispersed by ultrasonic dispersion. In the ethyl acetate solution, the proportion is 5wt%. During the experiment, attention should be paid to controlling the concentration. If the concentration is too high, the solution will be too viscous and become gelatinous. Secondly, a fixed ratio of 20wt% SBS / ethyl acetate and 5wt% CB / ethyl acetate solution was used for mixing to form a mixed solution of CB and SBS in ethyl acetate, wherein the ratio of CB to SBS was 1:4, Stir the mixed solution by magnetic force for more than 24 hours, stir evenly, so that the mate...

Embodiment 2

[0060] Embodiment 2 Foam sample preparation experiment

[0061] The experiment process is similar to that of Example 1, except that the pore-forming agent is replaced by sodium chloride, and the pore diameter ratio 1 of the polymer composite foam of SBS / CB is also larger.

Embodiment 3

[0062] Embodiment 3 foam sample preparation experiment

[0063] The experiment process is similar to that of Example 1, except that the pore-forming agent is replaced with coarse sugar for the experiment, and the pore size ratio 2 of the polymer composite foam of SBS / CB is also larger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com