A kind of biological magnetic nano coating and preparation method thereof

A nano-coating and biomagnetic technology, applied in the field of coatings, can solve the problems of high cost and high density, and achieve the effects of wide absorption frequency band, improved water resistance and scrub resistance, and good anti-electromagnetic radiation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

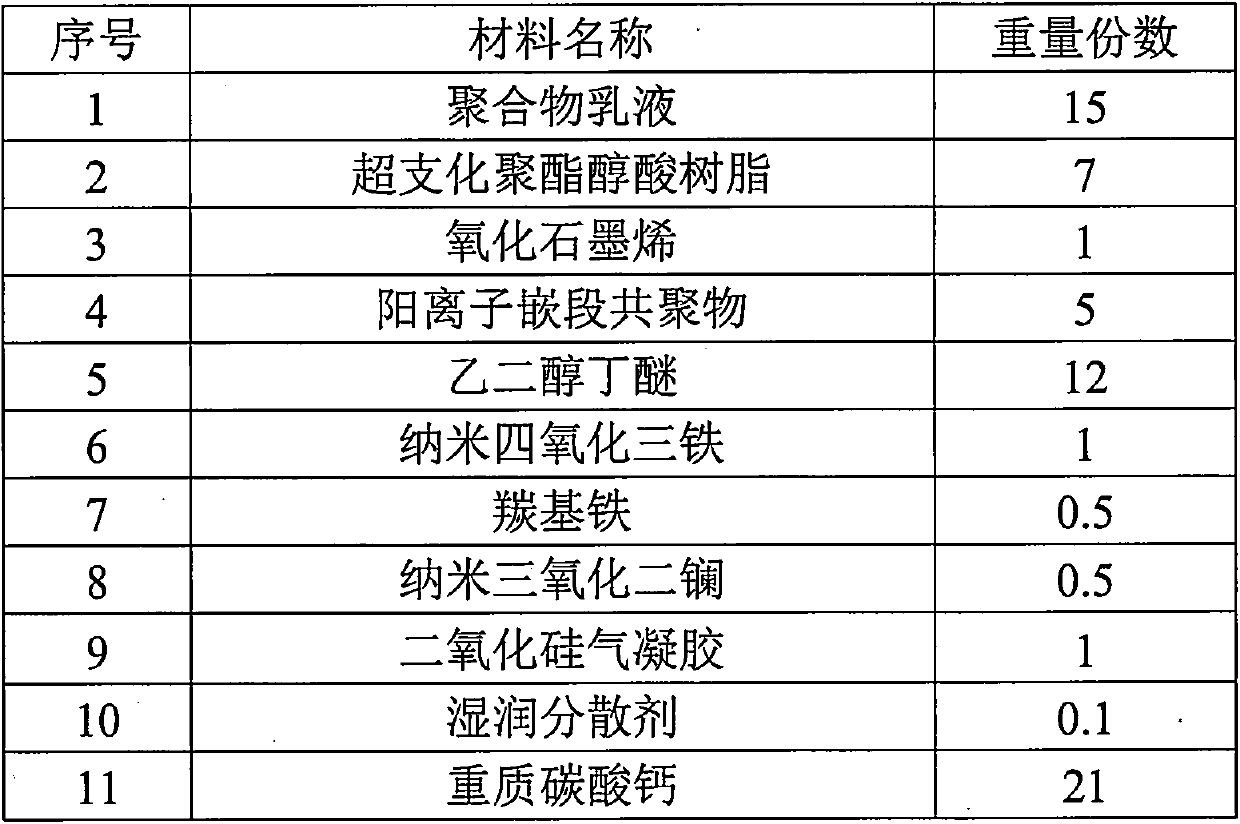

[0026] The raw material formula is shown in the following table:

[0027]

[0028]

[0029] Among them, the polymer emulsion is styrene-acrylic emulsion; the cationic block copolymer is P(MMA) 20 -b-P(METEA) 10 ; The particle size of nano ferric oxide is 10-20nm; the particle size of nano-lanthanum trioxide is 10-20nm; the defoamer is defoamer CF-16; The pore size of silica airgel is 80-100nm, the porosity is 90%-94%, and the dry density is 40-100kg / m 3 , The thermal conductivity is 0.010~0.025W / (m.K).

[0030] Preparation method: Add polymer emulsion, hyperbranched polyester alkyd resin, cationic block copolymer, ethylene glycol butyl ether, wetting and dispersing agent into a stirrer, stir evenly, then add graphene oxide and nano-ferric oxide , carbonyl iron, nano-lanthanum trioxide, silica aerogel, heavy calcium carbonate, defoamer, just stir evenly.

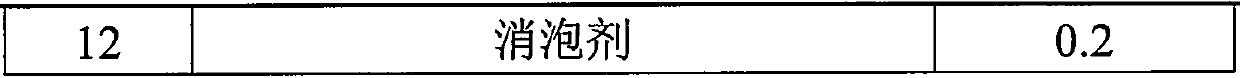

[0031] The performance of the coating that present embodiment obtains is shown in the table below:

[0032]

...

Embodiment 2

[0036] The raw material formula is shown in the following table:

[0037] serial number material name parts by weight 1 polymer emulsion 25 2 Hyperbranched Polyester Alkyd Resin 8 3 Graphene oxide 2 4 cationic block copolymer 7 5 Ethylene glycol butyl ether 20 6 Nano ferric oxide 2 7 carbonyl iron 0.6 8 Nano-lanthanum trioxide 0.6 9 Silica airgel 2 10 Wetting and dispersing agent 0.2 11 Ground calcium carbonate 24 12 Defoamer 0.3

[0038] Among them, the polymer emulsion is styrene-acrylic emulsion; the cationic block copolymer is P(MMA) 20 -b-P(METEA) 20 ; The particle size of nano ferric oxide is 10-20nm; the particle size of nano-lanthanum trioxide is 10-20nm; the defoamer is defoamer CF-16; The pore size of silica airgel is 80-100nm, the porosity is 90%-94%, and the dry density is 40-100kg / m 3 , The thermal conductivity is 0.010~0.025W / (m.K).

[0039] Preparation method:...

Embodiment 3

[0044] The raw material formula is shown in the following table:

[0045]

[0046]

[0047] Among them, the polymer emulsion is styrene-acrylic emulsion; the cationic block copolymer is P(MMA) 20 -b-P(METEA) 30 ; The particle size of nano ferric oxide is 10-20nm; the particle size of nano-lanthanum trioxide is 10-20nm; the defoamer is defoamer CF-16; The pore size of silica airgel is 80-100nm, the porosity is 90%-94%, and the dry density is 40-100kg / m 3 , The thermal conductivity is 0.010~0.025W / (m.K).

[0048] Preparation method: Add polymer emulsion, hyperbranched polyester alkyd resin, cationic block copolymer, ethylene glycol butyl ether, wetting and dispersing agent into a stirrer, stir evenly, then add graphene oxide and nano-ferric oxide , carbonyl iron, nano-lanthanum trioxide, silica aerogel, heavy calcium carbonate, defoamer, just stir evenly.

[0049] The performance of the coating that present embodiment obtains is shown in the table below:

[0050]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com