Preparation process of flocculant for treating dyeing wastewater and application method of flocculant

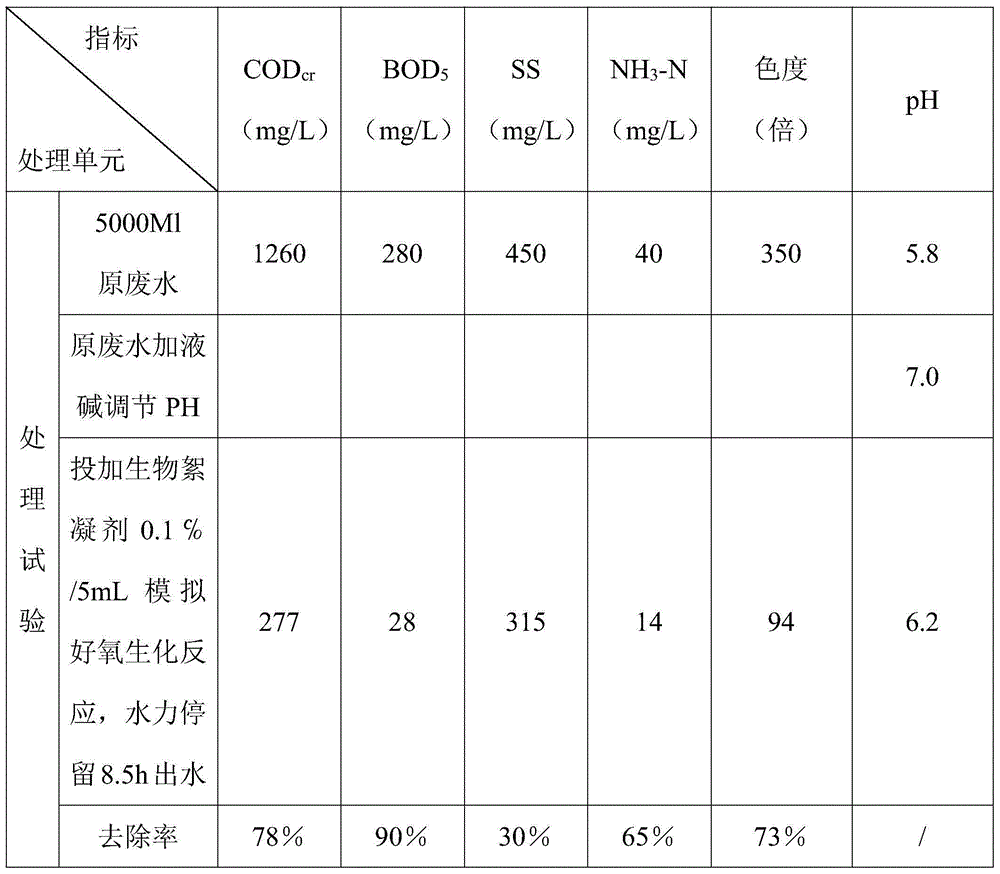

A printing and dyeing sewage and manufacturing process technology, which is applied in the direction of microorganism-based methods, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of high input cost, achieve complex structure, stable performance, and reduce CODcr.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A kind of manufacture craft of the flocculant of processing printing and dyeing sewage of the present invention, comprises the steps:

[0015] Ⅰ) Preparation of EM bacteria liquid: take clean water and boil, boil for a while, cool to a temperature of 23-25°C, take 10,000 parts of cooled water, add 1,000 parts of brown sugar, 1 part of EM bacteria, pour into a container and stir well, Cover the lid, slightly open a line of seams, and carry out facultative fermentation. The room temperature of the production place is 23-25°C. After opening the lid on the 10th day, add 1000 parts of honey, and then cultivate for 5 days with facultative fermentation. A total of 15 days to complete; check the EM bacteria liquid, the pH of the EM bacteria liquid is less than 3.8, the color is light brown or yellowish brown, there is a strong sweet-sour smell or sour smell, and a large amount of gas is produced, which is a qualified product. The EM strain, whose English name is Effective Micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com