A preparation method of bismuth-based thin film with high tuning rate

A bismuth-based, high-profile technology, applied in ion implantation plating, metal material coating process, coating, etc., to achieve the effect of good crystallinity, orientation and tuning performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

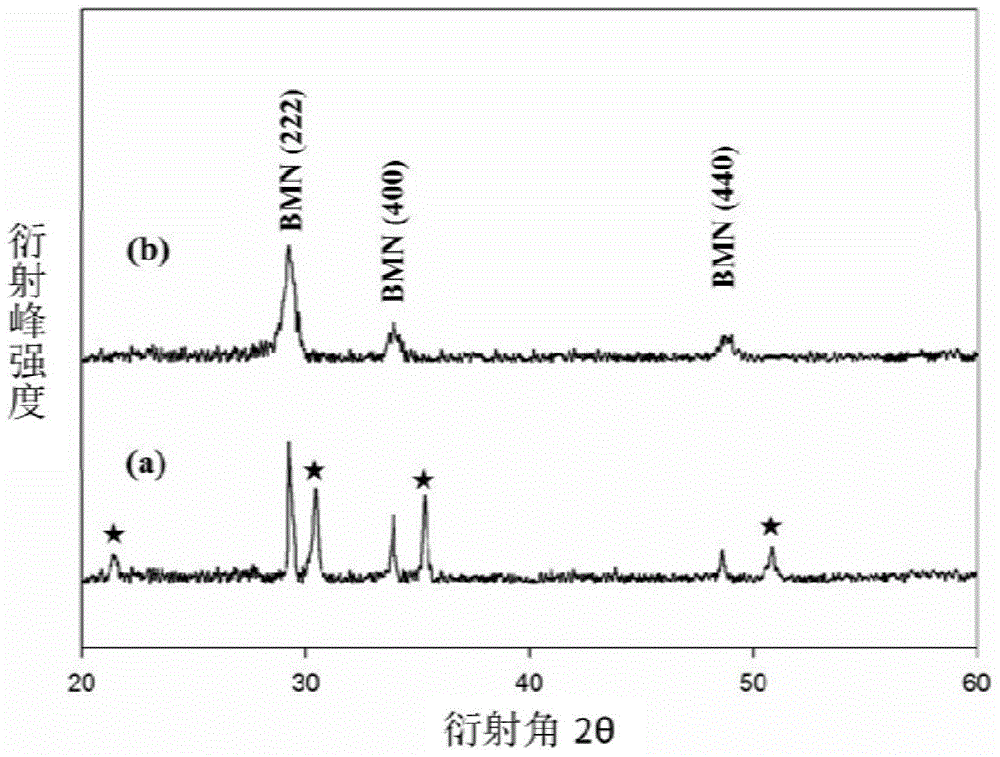

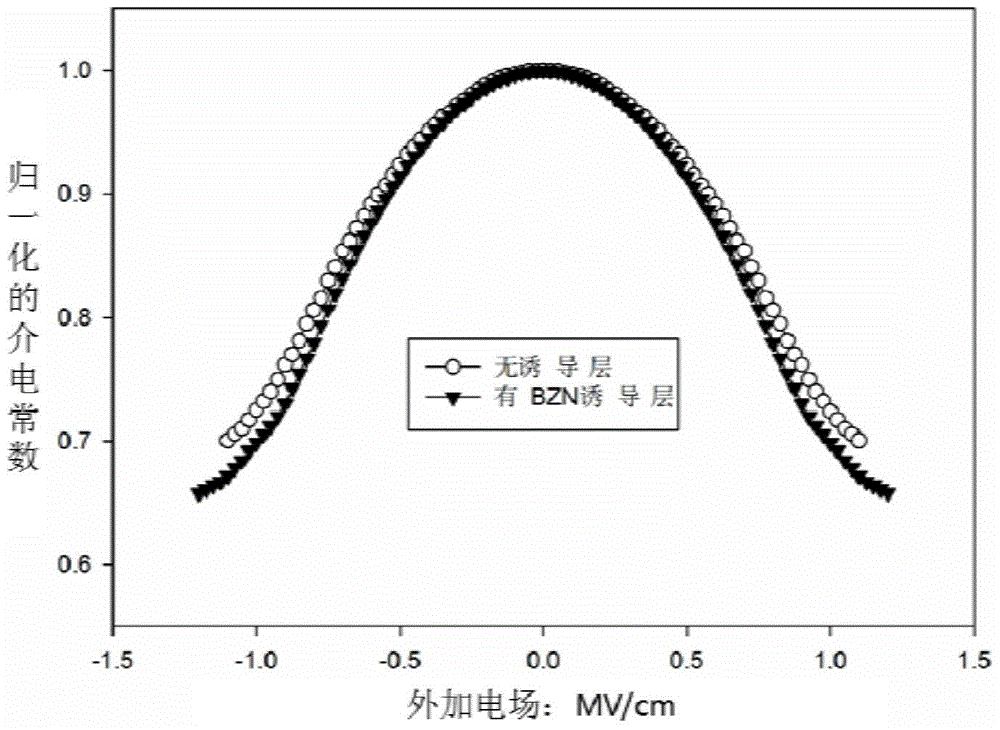

Image

Examples

Embodiment 1

[0027] (1) Clean the substrate substrate

[0028] Select a silicon substrate with a platinum electrode on the surface, place it in an alcoholic organic solvent for ultrasonic cleaning, rinse it with deionized water, and dry it in a nitrogen stream.

[0029] The substrate of the present invention may be a silicon substrate, an alumina substrate or a conductive glass substrate; the electrodes may be gold electrodes or platinum electrodes.

[0030] (2) Deposition induction layer

[0031] (a) Put the cleaned silicon substrate into the magnetron sputtering vacuum chamber, install the zinc bismuth niobate target on the corresponding radio frequency sputtering target, and start the vacuuming procedure.

[0032] (b) Wait until the vacuum degree reaches 9×10 -5 Torr, turn on the radio-frequency current source corresponding to the zinc-bismuth niobate target, pass in the working gas argon, complete radio-frequency magnetron sputtering, and prepare the zinc-bismuth niobate induction la...

Embodiment 2

[0041] The preparation process of Example 2 is the same as that of Example 1, except that the annealing temperature of the zinc-bismuth niobate induction layer is 650° C., and the tuning rate measured in Example 2 under the same conditions is 33%.

Embodiment 3

[0043] The preparation process of Example 3 is the same as that of Example 1, except that the annealing temperature of the zinc-bismuth niobate induction layer is 700° C., and the tuning rate measured in Example 2 under the same conditions is 31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com