Preparation method of ceramic-modified lithium-ion battery diaphragm

A technology for lithium ion batteries and separators, which is applied in the field of preparation of ceramic modified lithium ion battery separators, can solve the problems of short storage time, time-consuming, unstable dispersion, etc., avoid high temperature treatment, avoid uneven dispersion and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

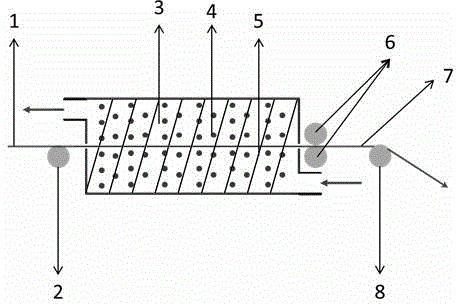

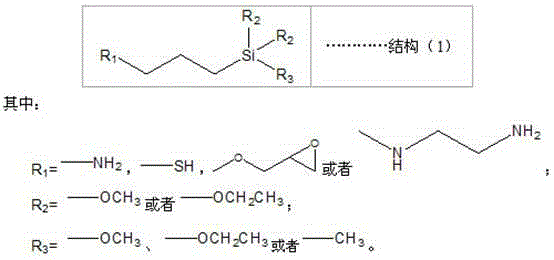

[0031] like figure 1 As shown, using CMC as a binder and water as a solvent, the solution is heated to 80°C, and then coated on a PE separator with a thickness of 10 μm (the PE separator is pre-treated with polydopamine) by dipping-pulling method. Obtain viscous slurry-coated diaphragm 1; at the same time, use the silane coupling agent KH560 to treat the silica ceramics with a D90 of 400nm, the dosage is 3% (mass fraction) of the silica ceramics, and use a Henschel high-speed mixer, After mixing at high speed for 1 hour, vacuum bake at 180° C. for 2 hours to obtain ceramic 4 treated with active material. The temperature of the fluidized bed chamber 3 is kept at 80°C by the heating wire 5, and the diaphragm is pulled forward by the roller 2 and the roller 3. Due to the viscosity of 1, ceramic particles will accumulate on its surface, and the excess particles are removed by a brush. After hot pressing by roller 6 and drying, a ceramic modified diaphragm is obtained.

Embodiment 2

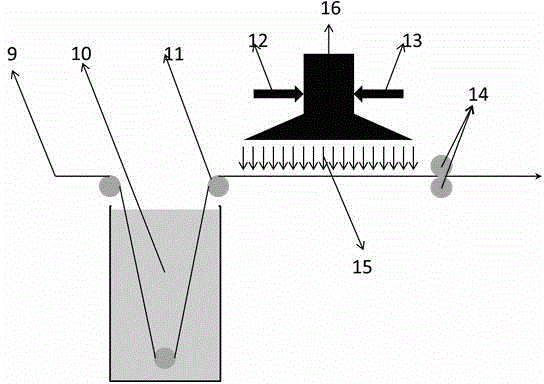

[0033] like figure 2 As shown, after heating the vinylidene fluoride-hexafluoropropylene copolymer / N,N-dimethylformamide solution to 80°C, place it in the cylinder 10, and after the diaphragm 9 passes through the cylinder, it hangs on its surface After a layer of wet film passes through the guide roller 11, the spray gun array 16 applies the atomized ceramic particles 15 on the surface of the wet film, and after being hot-pressed by the roller machine 14, it is dried to obtain a ceramic modified diaphragm. Here, the substrate diaphragm used is the surface of the PE diaphragm with a thickness of 16 μm, the silane coupling agent is KH540, the ceramic is alumina, the particle size D90 is 900nm, and the amount of KH540 is 2% (mass fraction) of the alumina ceramic. The method is to use a Henschel high-speed mixer, mix at high speed for 2 hours, and then vacuum bake at 180° C. for 2 hours to obtain active material-treated ceramics. The modified diaphragm obtained here has PVDF-HFP...

Embodiment 3

[0035]Using polyvinyl alcohol as a binder and water as a solvent, heat the solution to 80°C and apply it on one side of a PE separator with a thickness of 16 μm (pre-treated with polydopamine) to obtain a viscous slurry-coated separator At the same time, use silane coupling agent KH550 to treat zirconia ceramics with D90 of 500nm, the dosage is 2% (mass fraction) of zirconia ceramics, use Henschel high-speed mixer, after high-speed mixing for 4 hours (the density of zirconia ceramics is higher, The mixing time is longer), and vacuum baked at 180°C for 2 hours to obtain active material-treated ceramics. Then use a spray gun to atomize and spray the obtained modified ceramic particles on the surface of the wet diaphragm with compressed air to control the coating thickness to 5 μm, then hot press with a pair of rollers, and then dry to obtain a ceramic modified diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com