Double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method

A high-frequency pulse, argon arc welding technology, used in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of inability to guarantee the welding seam formation and quality of stainless steel plates, affecting the welding seam formation and quality, and increasing the number of times the welding seam is heated. and other problems, to achieve the effect of reducing porosity sensitivity, reducing the amount of weld metal filling, and increasing the thickness of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

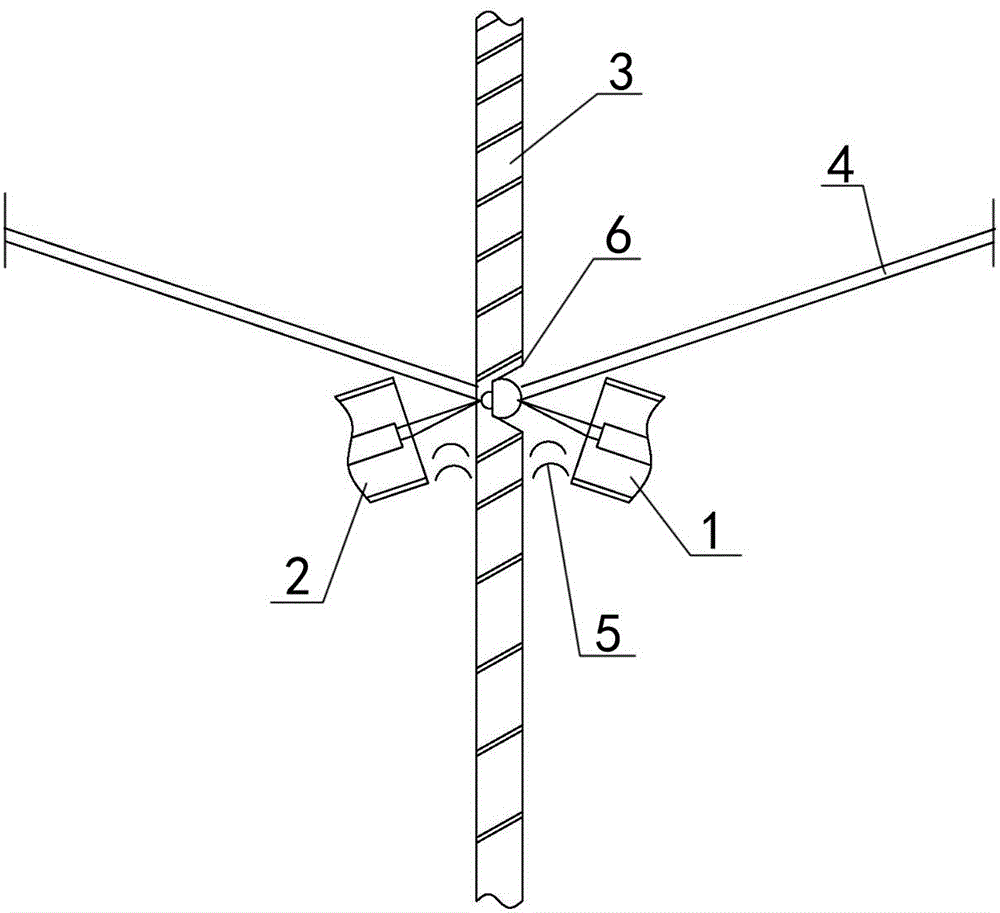

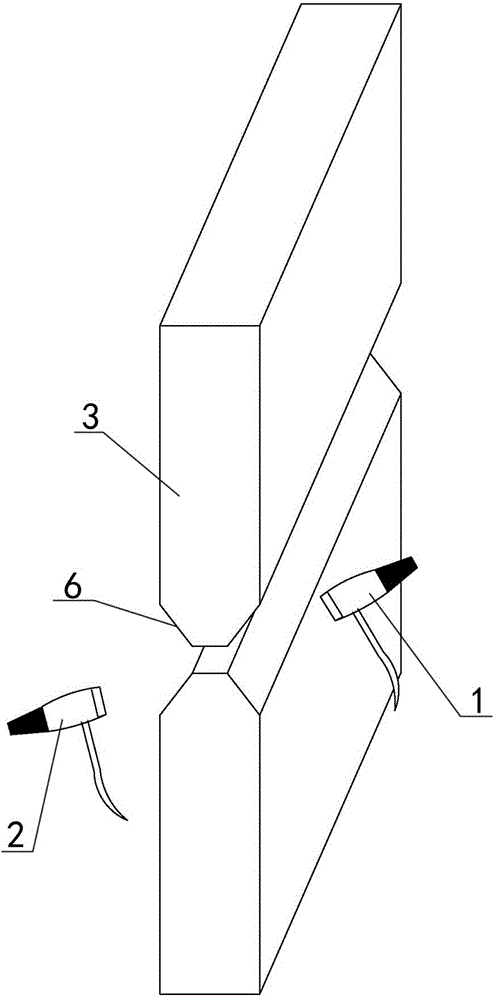

[0040] In this example, the stainless steel storage tank made of SUS304 material is welded to the stainless steel storage tank as an illustration. The diameter of the stainless steel storage tank to be made is 12m, and the height is 21m. The height is 1.5m, and the thickness from bottom to top is 16mm, 14mm, 12mm, 12mm, 10mm, 10mm, 8mm, 8mm, 8mm, 6mm, 6mm, 6mm, 6mm, 6mm.

[0041] The embodiment adopts a two-person double-sided synchronous tungsten electrode pulse argon arc butt welding method, the outer side of the weld seam is the main welding torch, the welding torch equipment is MSM-400 inverter DC high-frequency pulse argon arc welding machine, and the inner side of the weld seam is the auxiliary welding torch , The welding torch equipment is ZXT-400STG DC argon arc welding machine.

[0042] MSM-400 inverter DC high-frequency pulse argon arc welding machine: The welding current changes at a very high frequency of thousands or even tens of thousands of times per second. Suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com