A kind of preparation method of zinc tungstate crystal with nanometer size

A technology of nanometer size and zinc tungstate, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of large product particle size, high energy consumption of synthetic powder, complicated preparation process, etc., and achieve low cost, Reduce the synthesis temperature and facilitate the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

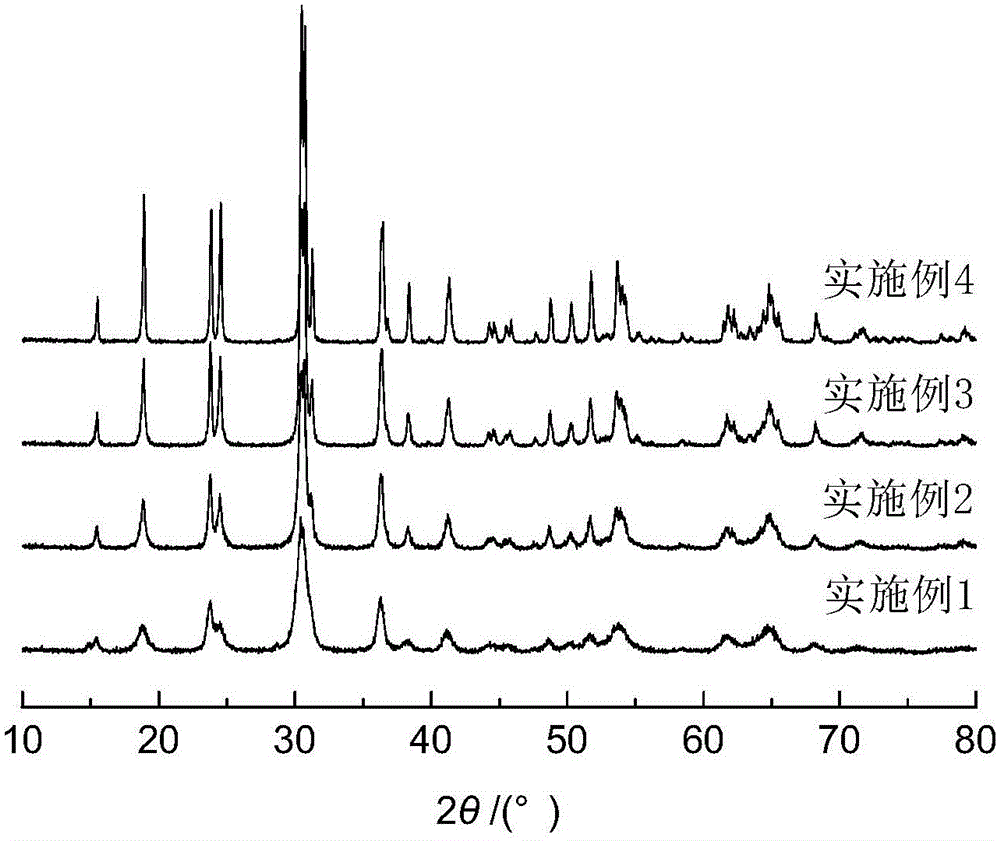

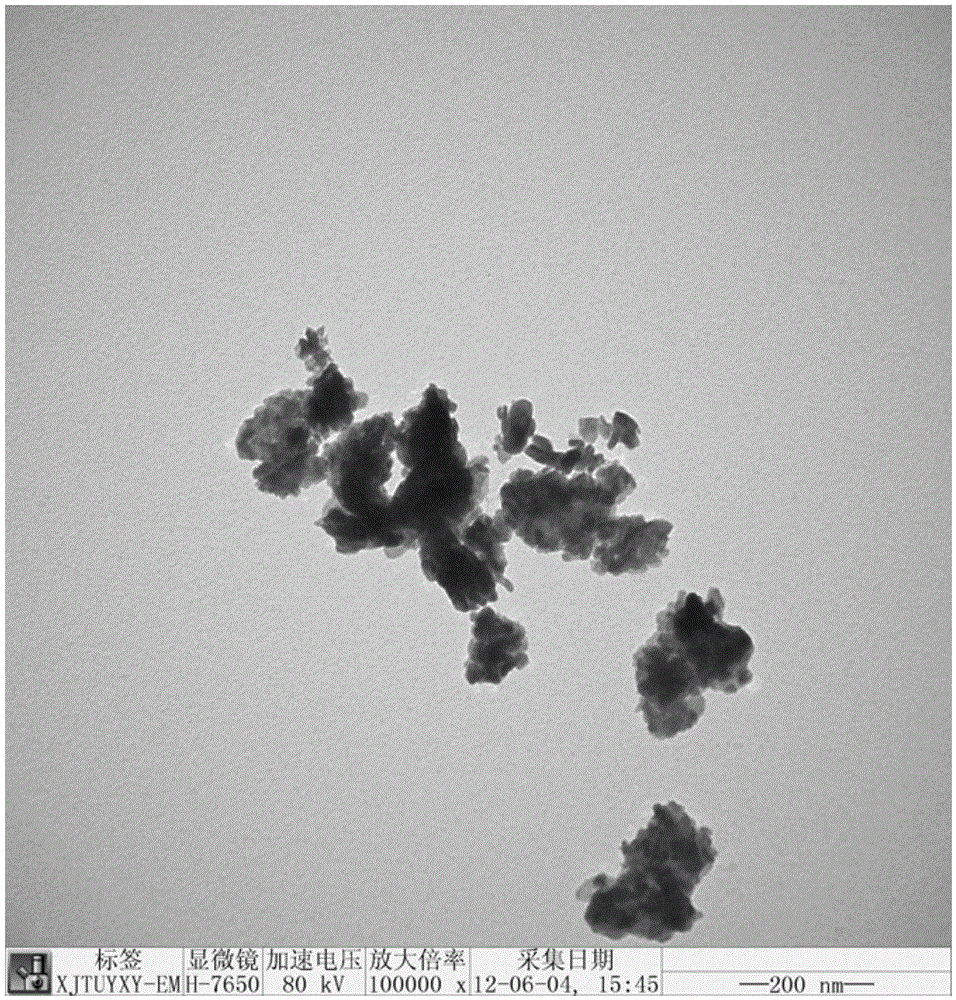

Embodiment 1

[0024] Step 1. Put the main raw material and the molten salt raw material in a ball mill at a mass ratio of 1:12, use absolute ethanol as the ball milling medium, use zirconium balls as the milling balls, and mix them for 4 hours, then dry them at 50°C to obtain a mixed Powder; the main raw material is sodium tungstate and zinc oxalate, the molar ratio of sodium tungstate and zinc oxalate is 1.5:1; the molten salt raw material is a mixture of lithium nitrate and potassium chloride, lithium nitrate and potassium chloride The mol ratio is 3:2; The quality of described dehydrated alcohol is equal to the mass summation of main raw material and molten salt raw material;

[0025] Step 2: Heat the mixed powder described in step 1 in an oil bath to 300°C under stirring conditions, and then heat and stir for 4 hours to obtain zinc tungstate powder;

[0026] Step 3. Repeatedly washing the zinc tungstate powder described in step 2 with deionized water until the washing solution does not ...

Embodiment 2

[0028] Step 1. Put the main raw material and the molten salt raw material in a ball mill at a mass ratio of 1:14, use absolute ethanol as the ball milling medium, and use zirconium balls as the milling balls, mix for 4 hours, and then dry at 55°C to obtain a mixed Powder; the main raw material is sodium tungstate and zinc oxalate, the molar ratio of sodium tungstate and zinc oxalate is 1.5:1; the molten salt raw material is a mixture of lithium nitrate and potassium chloride, lithium nitrate and potassium chloride The mol ratio is 3:2; The quality of described dehydrated alcohol is equal to the mass summation of main raw material and molten salt raw material;

[0029] Step 2: Heat the mixed powder described in step 1 in an oil bath to 350°C under stirring conditions, and then heat and stir for 3 hours to obtain zinc tungstate powder;

[0030] Step 3. Repeatedly washing the zinc tungstate powder described in step 2 with deionized water until the washing liquid does not contain ...

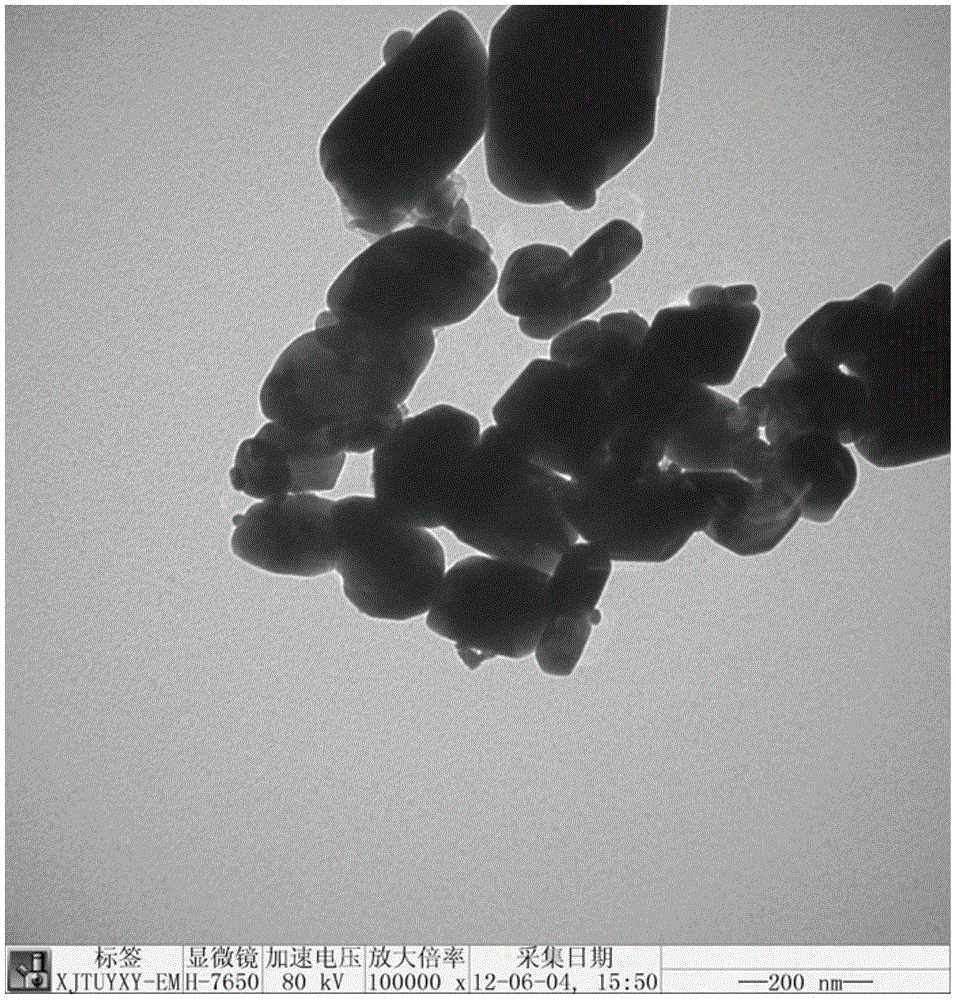

Embodiment 3

[0032] Step 1. Put the main raw material and the molten salt raw material in a ball mill at a mass ratio of 1:15, use absolute ethanol as the ball milling medium, and use zirconium balls as the milling balls, mix for 4 hours, and then dry at 60°C to obtain a mixed Powder; the main raw material is sodium tungstate and zinc oxalate, the molar ratio of sodium tungstate and zinc oxalate is 2:1; the molten salt raw material is a mixture of lithium nitrate and potassium chloride, lithium nitrate and potassium chloride The mol ratio is 3:3; The quality of described dehydrated alcohol is equal to the mass summation of main raw material and molten salt raw material;

[0033] Step 2: Heat the mixed powder mentioned in step 1 in an oil bath to 400°C under stirring conditions, and then heat and stir for 2 hours to obtain zinc tungstate powder;

[0034] Step 3. Repeatedly washing the zinc tungstate powder described in step 2 with deionized water until the washing liquid does not contain ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com