Conductive adhesive preparation method and conductive adhesive

A technology of conductive adhesive and conductive particles, applied in conductive materials, conductive adhesives, adhesives and other directions dispersed in non-conductive inorganic materials, can solve the problem of poor electrical conductivity and mechanical properties, graphene cannot be dispersed, electroplating Process environment pollution and other problems, to achieve the effect of improving conductivity, improving dispersion and uniformity, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

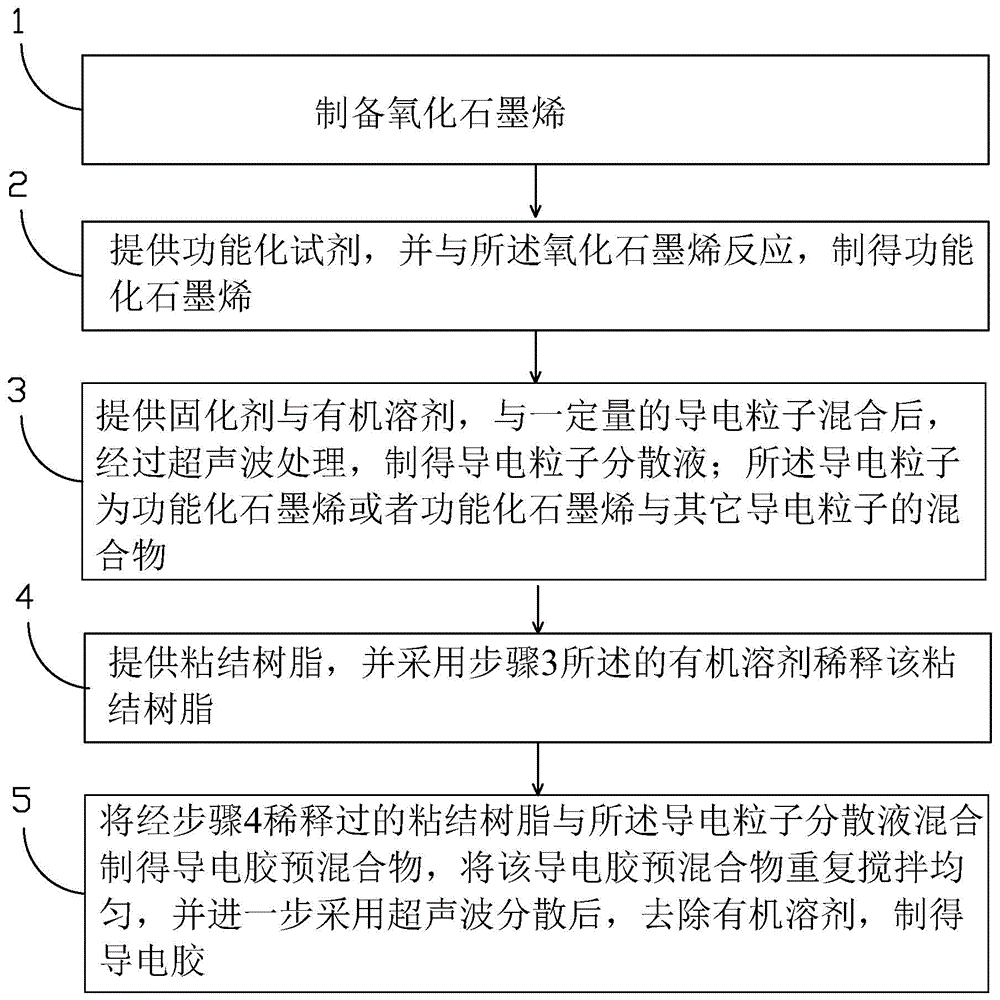

[0034] see figure 1 , the invention provides a kind of preparation method of conductive glue, comprises the following steps:

[0035] Step 1, preparing graphene oxide;

[0036] The method for preparing graphene oxide in the step 1 is the Hummers method.

[0037] Step 2, providing a functionalized reagent, and reacting with the graphene oxide to prepare functionalized graphene;

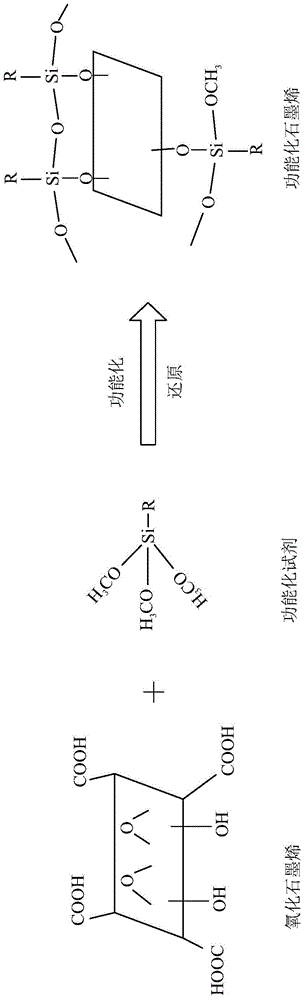

[0038] see figure 2 , in the step 2, the functionalization reagent reacts with the functional groups on the surface of graphene oxide, introduces functionalized molecules on the surface of graphene oxide, and reduces other oxygen-containing functional groups on the surface of graphene oxide to obtain functional Graphene; by introducing functionalized molecules containing polar groups on the surface of the functionalized graphene, the dispersion of the functionalized graphene in the binder resin is improved.

[0039] The general structural formula of the functionalized reagent is: Wherein the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com