Mixed additive for electrolytic profile-free copper foil

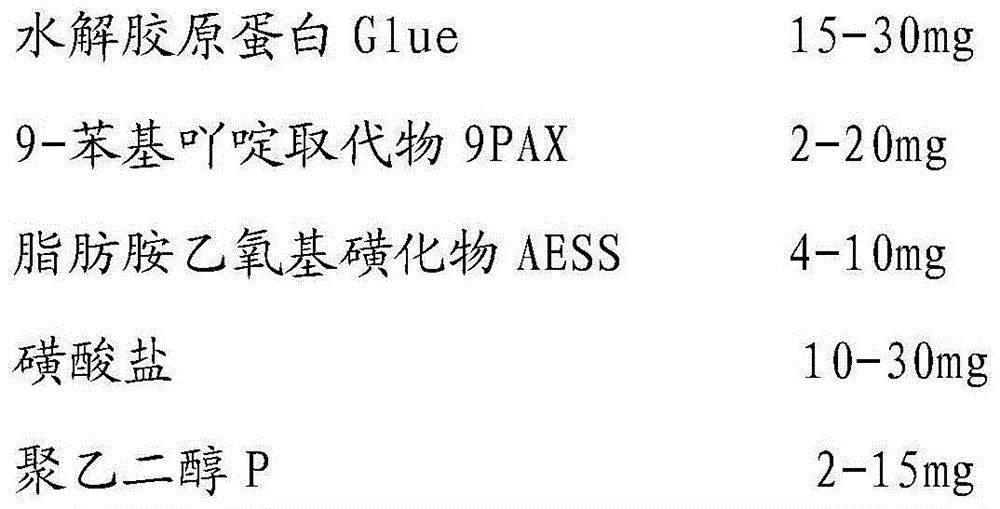

A mixed additive, contourless technology, applied in the electrolysis process, electroforming, etc., can solve the problems of low elongation, large side effects, poor bright effect, etc., and achieve the effect of easy-to-obtain raw materials, simple components, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A mixed additive for electrolytic contourless copper foil, containing 25 mg of Glue, 8 mg of 9PAX, 6.5 mg of AESS, 15 mg of SPS, 4 mg of P(6000), 10.3 mg of H, 50 g of sulfuric acid and 20 g of copper sulfate pentahydrate in each liter of the aqueous solution of the mixed additive.

[0029] Wherein, the molecular structure of the 9-phenylacridine substituent is:

[0030] R 1-3 : H, Cl, CH 3 、C 2 h 5 or phenyl.

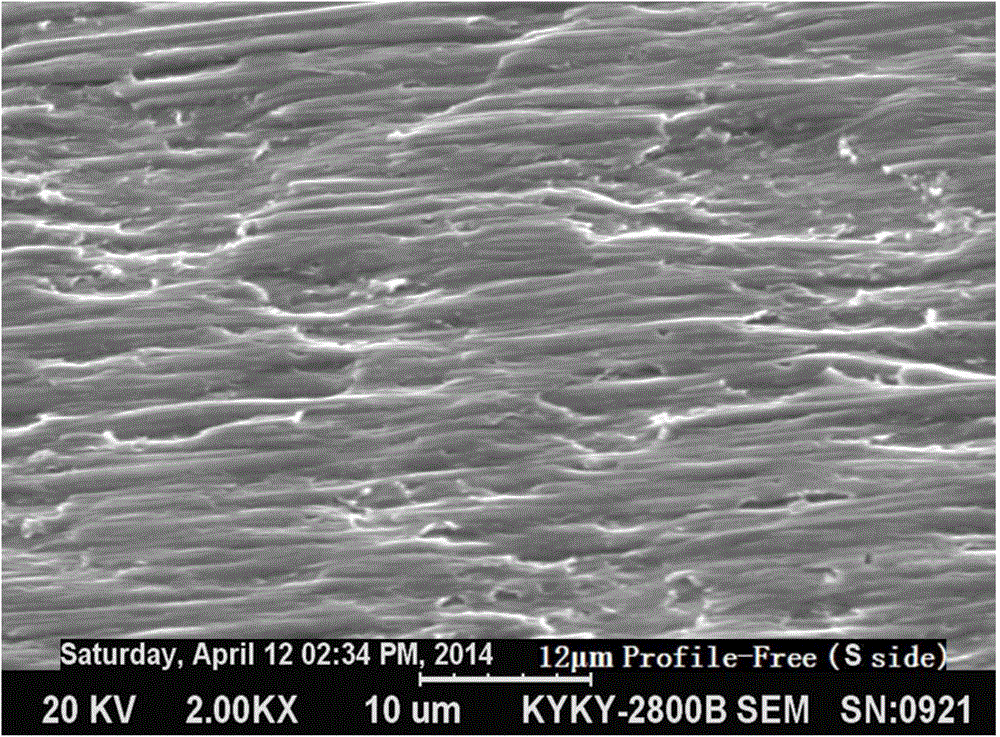

[0031] In Cu 2+ 80±2g / L, H 2 SO 4 110±5g / L, Cl-20-60mg / L, electrolytic current density 69A / dm 2, into a solution with a voltage of 4.0V and a temperature of 54±2°C, add the above-mentioned mixed additives at a speed of 100ml / min, use a titanium roller as the cathode, and titanium-coated nano-active materials as the anode, electrodeposit and continuously peel off, by controlling the cathode A 12μm-thick contourless copper foil was obtained at a rotational speed of

[0032] The matte surface (crystal growth surface) of the copper foil obtained in this e...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is:

[0035] The aqueous solution of mixed additives per liter contains: Glue 20mg, 9PAX 6mg, AESS 10mg, MPS 20mg, P(6000) 5mg, H 10.4mg, sulfuric acid 50g and copper sulfate pentahydrate 20g. The matte surface of the obtained copper foil (crystal growth surface) Rz0.7μm, gloss (60°) 720, normal temperature tensile strength 664MPa, normal temperature elongation 14%, high temperature (180 ℃) tensile strength greater than 284MPa, high temperature elongation 12 %.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is:

[0038] The aqueous solution of mixed additives per liter contains: Glue28mg, 9PAX10mg, AESS8mg, DPS18mg, P(10000)6mg, H10.5mg, sulfuric acid 50g and copper sulfate pentahydrate 20g. The matte surface of the obtained copper foil (crystal growth surface) Rz0.9μm, gloss (60°) 715, normal temperature tensile strength 618MPa, normal temperature elongation 12.4%, high temperature (180°C) tensile strength 271MPa, high temperature elongation 11.2% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com