Method for preparing magnetic powder core with high-flux magnet ring performance

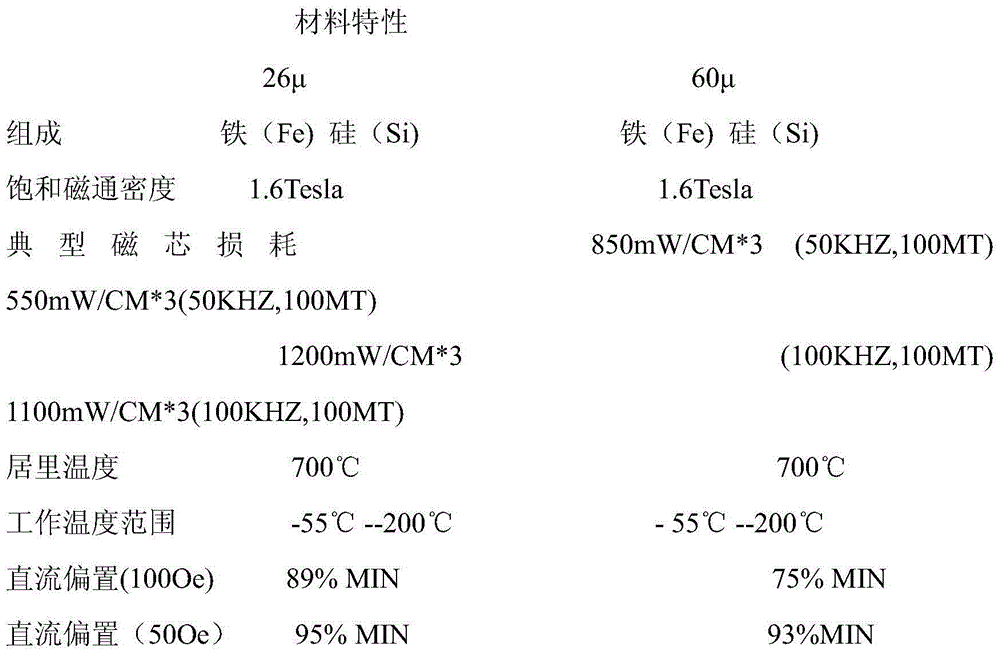

A high-flux, magnetic powder core technology, used in inductor/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problem of high price, achieve the effect of low cost, high AC and DC superposition characteristics, and low core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Put the iron-silicon alloy into a vacuum induction furnace for smelting, the silicon content in the iron-silicon alloy is 5%, and the balance is iron, and then the iron-silicon alloy is fired into a solution at 750 ° C, and the solution is 8m high. The container is crushed by high-pressure nitrogen, and then put into a heat treatment furnace under nitrogen protection for annealing treatment at 720°C. After cooling to room temperature, the obtained powder is passed through a 180-mesh sieve;

[0023] (2) surface passivation is carried out on the powder obtained in step (1), and the powder is stirred evenly with 2wt% phosphoric acid and 4wt% water, and then placed in a stirring vessel, then heated and dried at a temperature of 90° C., after being completely dried, put into the powder Add insulating agent, internal lubricant and mold release agent, and then carry out molding, and the molding pressure is 18T / cm 2 , and then heat treatment. The heat treatment is divided i...

Embodiment 2

[0030] (1) Put the iron-silicon alloy into a vacuum induction furnace for smelting, the silicon content in the iron-silicon alloy is 8%, and the balance is iron, and then the iron-silicon alloy is fired into a solution at 750 ° C, and the solution is 12m high. The container is crushed with high-pressure nitrogen, and then put into a heat treatment furnace under nitrogen protection for annealing treatment at 720°C. After cooling to room temperature, the obtained powder is passed through a 400-mesh sieve;

[0031] (2) the powder obtained in step (1) is subjected to surface passivation, stirred with 3 wt % phosphoric acid and 5 wt % of water and put into a stirring vessel, then heated and dried at 110° C., after complete drying, put into the powder Add insulating agent, internal lubricant and mold release agent, and then carry out molding, and the molding pressure is 18T / cm 2 , and then heat treatment. The heat treatment is divided into three areas: preheating zone, high temperat...

Embodiment 3

[0038] (1) Put the iron-silicon alloy into a vacuum induction furnace for smelting, the silicon content in the iron-silicon alloy is 6.5%, and the balance is iron, and then the iron-silicon alloy is sintered into a solution at 750 ° C, and the solution is 10m high. The container is crushed with high-pressure nitrogen, and then put into a heat treatment furnace under nitrogen protection for annealing treatment at 720°C. After cooling to room temperature, the obtained powder is passed through a 200-mesh sieve;

[0039] (2) surface passivation is carried out to the powder obtained in step (1), and the powder is uniformly stirred with 2.5wt% phosphoric acid and 4.5wt% water, and then placed in a stirring vessel, then heated and dried at a temperature of 100° C. Add insulating agent, internal lubricant and mold release agent to the powder, and then carry out molding, and the molding pressure is 18T / cm 2, and then heat treatment. The heat treatment is divided into three areas: prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com