Processing stock solution of polyimide fiber or film, preparation method and applications thereof

A polyimide fiber, a technology for processing raw liquid, applied in the chemical characteristics of fibers, textiles and papermaking, single-component synthetic polymer rayon, etc. The process is simple, the price is low, and the equipment is universal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

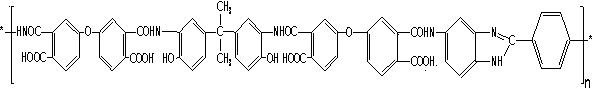

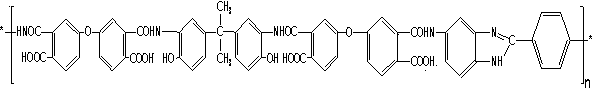

Image

Examples

Embodiment 1

[0025] 1.1 Preparation of processing stock solution

[0026] At room temperature, add 25.8g (0.1mol) of 2,2-bis(3-amino-4-hydroxyphenyl)propane and 260ml of N-methyl-2-pyrrolidone into the reactor, stir and dissolve, then add 62.0g (0.2mol) powder of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stirred at 3°C for 0.6h, then added 22.4g (0.1mol) 2-(4-aminophenyl )-5-aminobenzimidazole, stirred and reacted for 3.5 hours at a temperature of 3° C. to obtain a homogeneous and viscous polyamic acid processing stock solution. Measured by BROOKFIELD's CAP2000+ vertebral plate viscometer, its viscosity at 80°C is 2436mPa.s.

[0027] 1.2 Preparation of polyimide film

[0028] Take an appropriate amount of the processing stock solution prepared in 1.1, evenly coat it on a clean flat glass sheet, and put it into a blast high-temperature oven to solidify to form a film. The specific process is: raise the temperature from room temperature to 130°C and keep it for 60 minutes; ℃...

Embodiment 2

[0032] 2.1 Preparation of processing stock solution

[0033] At room temperature, add 25.8g (0.1mol) of 2,2-bis(3-amino-4-hydroxyphenyl)propane and 260ml of N-methyl-2-pyrrolidone into the reactor, stir and dissolve, then add 62.0g (0.2mol) powder of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stirred at 2°C for 0.8h, then added 22.4g (0.1mol) 2-(4-aminophenyl )-5-aminobenzimidazole, stirred and reacted for 4 hours at a temperature of 2° C. to obtain a homogeneous and viscous polyamic acid processing stock solution. Measured by BROOKFIELD's CAP2000+ laminar viscometer, its viscosity at 80°C is 2485mPa.s.

[0034] 2.2 Preparation of polyimide film

[0035]Take an appropriate amount of the processing stock solution prepared in 2.1, evenly coat it on a clean flat glass sheet, put it into a blast high-temperature oven, and solidify it into a film. ℃, keep for 60min; continue to raise the temperature to 280℃, keep for 60min, stop heating, cool down to room temperature ...

Embodiment 3

[0039] 3.1 Preparation of processing stock solution

[0040] At room temperature, add 25.8g (0.1mol) of 2,2-bis(3-amino-4-hydroxyphenyl)propane and 260ml of N-methyl-2-pyrrolidone into the reactor, stir and dissolve, then add 62.0g (0.2mol) powder of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stirred at 5°C for 0.9h, then added 22.4g (0.1mol) 2-(4-aminophenyl )-5-aminobenzimidazole, stirred and reacted for 4.5 hours at a temperature of 5° C. to obtain a homogeneous and viscous polyamic acid processing stock solution. Measured by BROOKFIELD's CAP2000+ vertebral plate viscometer, its viscosity at 80°C is 2503mPa.s.

[0041] 3.2 Preparation of polyimide film

[0042] Take an appropriate amount of the processing stock solution prepared in 3.1, evenly coat it on a clean flat glass sheet, and put it into a blast high-temperature oven to solidify and form a film. The specific process is: raise the temperature from room temperature to 130°C and keep it for 60 minutes; ℃,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com