A urea scale removing device used for a bottom tail tube of a flue gas denitration urea pyrolyzing furnace

A pyrolysis furnace and urea technology, applied in the field of flue gas denitrification equipment, can solve problems such as large heat consumption, urea blockage, atomizing nozzle failure, etc., and achieve the effects of easy maintenance and maintenance, high energy utilization, and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are further detailed descriptions of the present invention.

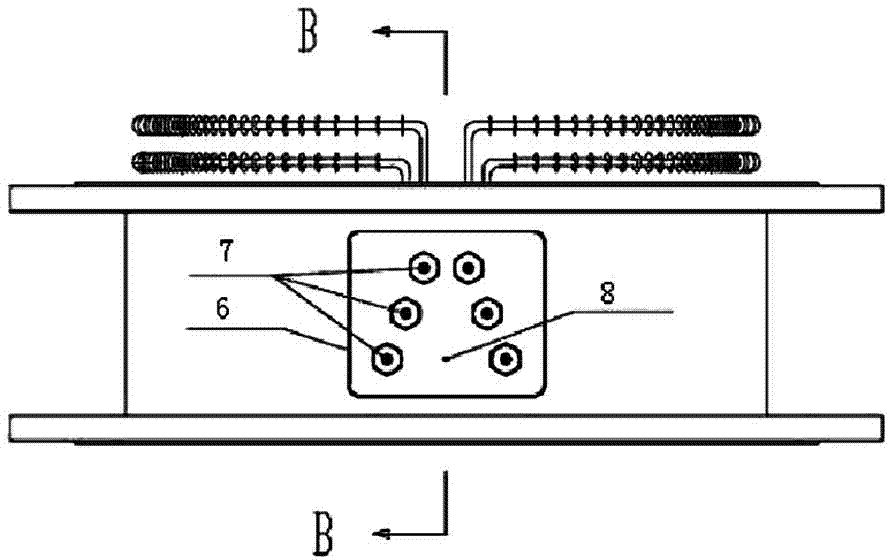

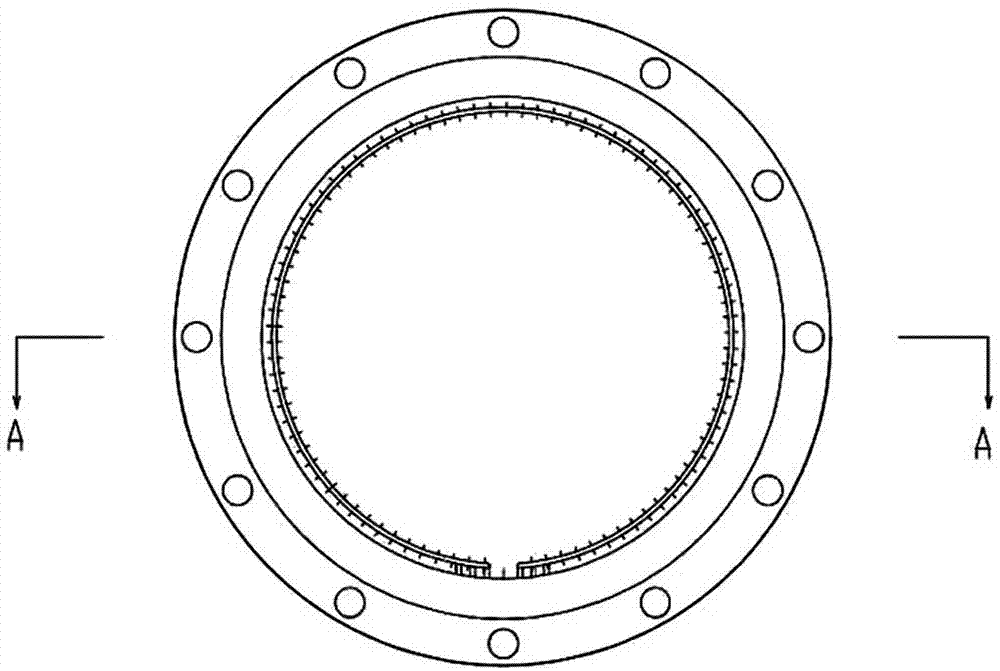

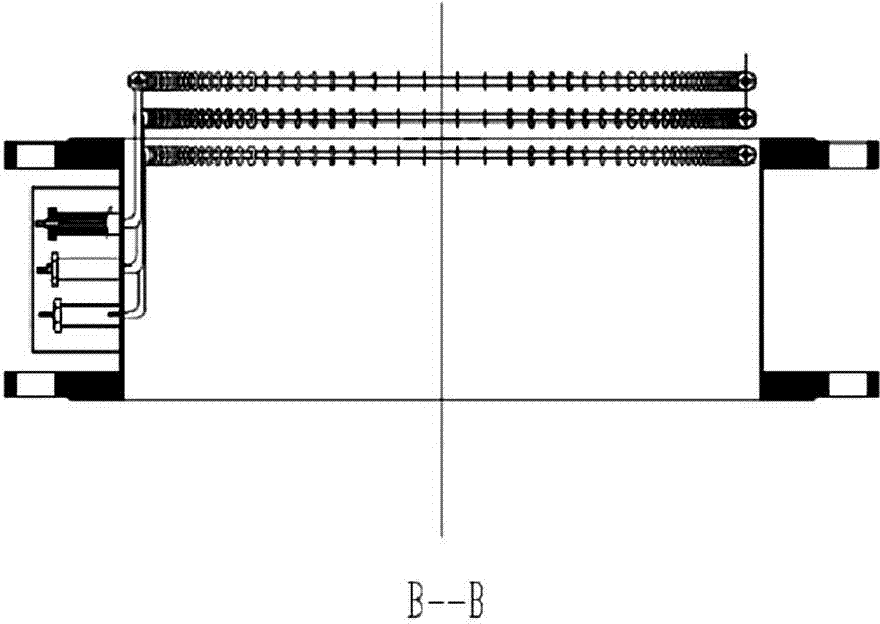

[0024] Examples see Figure 1-6 As shown, the urea decomposition device for the bottom tailpipe of the urea pyrolysis furnace used for flue gas denitrification consists of an electric heating body part and an electric control part. In the actual operation process, the urea solution is atomized in the pyrolysis furnace and decomposed at 350°C to 600°C, mixed with ammonia gas, hot air and possibly undecomposed urea through the tailpipe at the bottom of the pyrolysis furnace, urea The pyrolysis device enters the hot air duct and enters the catalyst layer through the ammonia injection grid for selective catalytic reduction and denitrification reaction. The urea decomposition device can control the opening and closing of the relay of the decomposition device according to the temperature measurement signal of the thermal resistance at the bottom of the pyrolysis furnace to control the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com