A2O(anaerobic-anoxic-oxic)-MBR (membrane bioreactor) sewage treatment device and method

A sewage treatment device and water outlet technology, applied in the field of A2O-MBR sewage treatment device, can solve the problems of high energy consumption, limited effluent water quality, poor phosphorus removal effect, etc., so as to reduce the energy consumption of the system operation, improve the effective utilization rate, The effect of saving the amount of aerobic aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

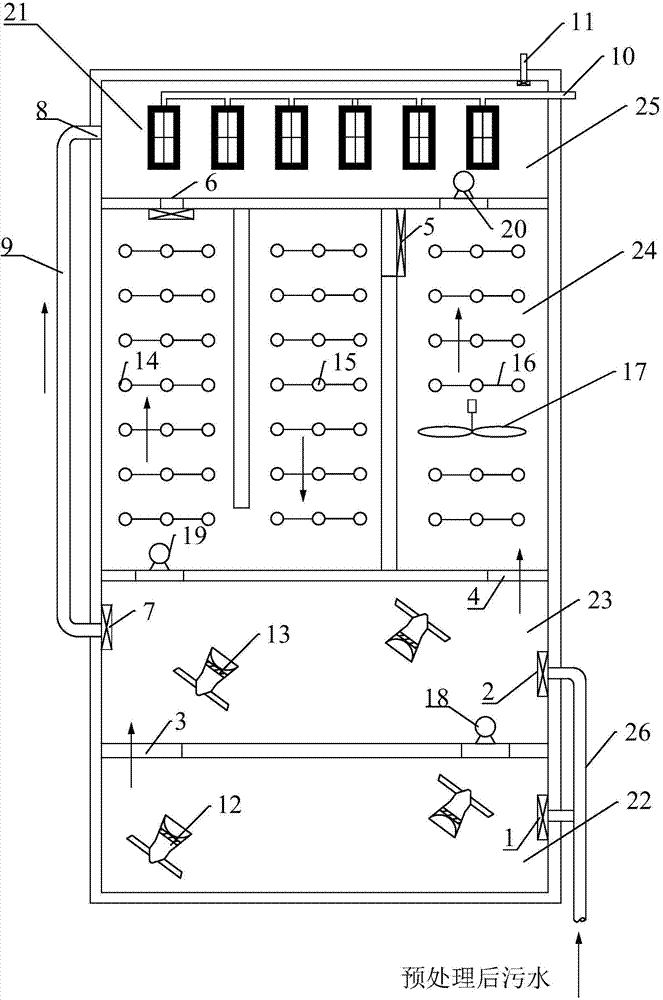

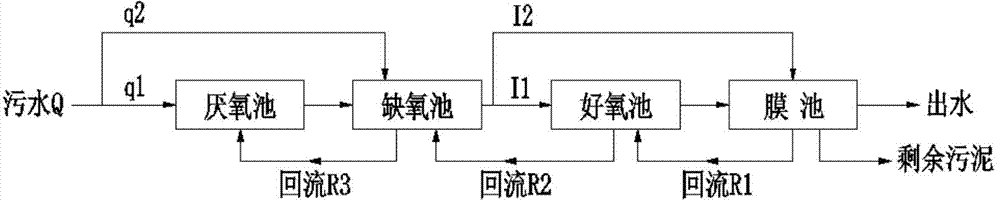

[0045] Use the device of the present invention to carry out the method for sewage treatment, comprise steps: the sewage after pretreatment flows into anaerobic pond 22 and the second water inlet 2 respectively through first water inlet hole 1 and flows into anoxic pond 23; Under the action of the first water inlet hole 1, the sewage flowing into the anaerobic tank 22 is completely mixed with the anoxic tank mixed solution pumped through the first mixed solution return pump 18; the mixed solution after the biochemical treatment of the anaerobic tank 22 is The first water outlet hole 3 enters the anoxic pool 23, and under the action of the second agitator 13, it is completely mixed with the sewage flowing in from the second water inlet hole 2 and the mixed liquid in the aerobic pool pumped by the second mixed liquid return pump 19, And biochemical reaction takes place here; the mixed solution in the anoxic tank 23 flows into the aerobic tank partly through the second water outlet...

Embodiment 2

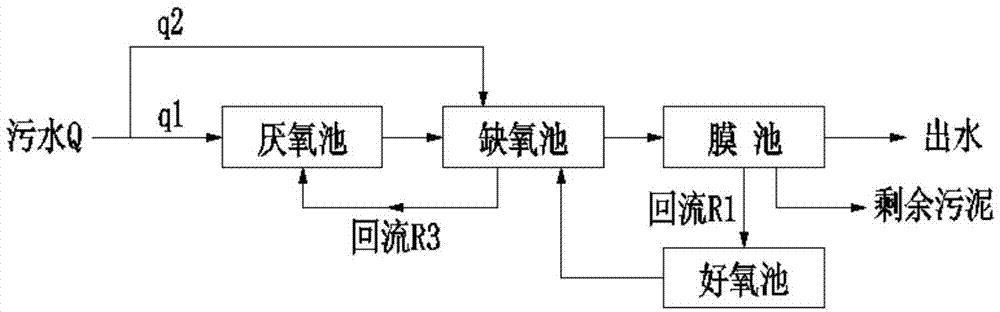

[0052] The difference between this embodiment and Example 1 is: the valve at the fourth water outlet in the anoxic pool is fully opened, the gate at the connecting hole between the first corridor and the second corridor in the aerobic pool, and the valve at the third water outlet The sluice gate is closed, the second mixed liquid return pump, the second aeration facility, and the third aeration facility are closed. The mixed solution treated in the anaerobic tank and the anoxic tank all flows into the membrane tank through the fourth outlet hole, the second pipe, and the fifth outlet hole; The three mixed liquid reflux pumps are pumped into the first corridor of the aerobic pool; the mixed liquid after the aerated biochemical reaction in the first corridor of the aerobic pool flows into the anoxic pool through the second outlet hole.

[0053] The schematic diagram of the technological process of this embodiment is shown in image 3 shown.

[0054] In this example, the amount...

Embodiment 3

[0056] This embodiment is different from Embodiment 2 in that: the first aeration facility, the second aeration facility, and the third aeration facility in the aerobic tank are all closed, and the push flow facility in the first corridor of the aerobic tank is opened; The high dissolved oxygen produced by the strong aeration of the membrane tank makes the mixed solution of the membrane tank pumped into the first corridor of the aerobic tank through the third mixed solution return pump still maintain a high dissolved oxygen. The first corridor of the oxygen pool can continue to carry out biochemical reactions such as aerobic nitrification, removal of ammonia nitrogen and other pollutants; Also in sequence naturally undergoes aerobic-anoxic habitats.

[0057] The schematic diagram of the technological process of this embodiment is shown in Figure 4 shown.

[0058] In this example, the amount of sewage entering the anaerobic pool and the anoxic pool after pretreatment (based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com