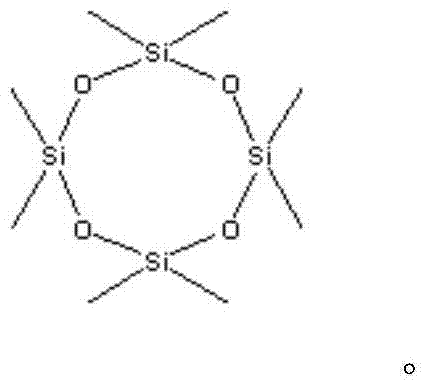

Method for producing cyclosiloxane through solvent oil catalytic cracking

A technology of catalytic cracking and siloxane, applied in the direction of silicon organic compounds, etc., can solve the problems affecting the overall yield of ring products, the yield cannot be improved, the labor intensity of slag discharge is high, and the speed of molecular diffusion can be accelerated. The effect of saving energy and reducing the amount of flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for producing cyclic siloxane by catalytic cracking of solvent oil, comprising the following steps:

[0025] (1) First vacuumize the cracking tank, control the pressure to -0.097MPa, and slowly raise the temperature of the cracking tank to 120°C;

[0026] (2) add stearyl alcohol in cracking kettle;

[0027] (3) After turning on the stirrer, add dimethyldichlorosilane hydrolyzate and KOH solution with a mass fraction of 45% into the cracking kettle, the volume ratio of KOH solution to hydrolyzate is 1:1000

[0028] (4) Heating the reaction kettle, controlling the temperature in the cracking kettle to be 130° C., and the cracking reaction is carried out;

[0029] (5) After cracking reaction for a period of time, when the liquid level of cracking tank rose to 90% of the total volume of cracking tank, the amount of discharge at the bottom was significantly reduced, and the reaction was stopped to replace stearyl alcohol, and continued according to steps (1)-(5) P...

Embodiment 2

[0032] A method for producing cyclic siloxane by catalytic cracking of solvent oil, comprising the following steps:

[0033] (1) First vacuumize the cracking tank, control the pressure to -0.097MPa, and slowly raise the temperature of the cracking tank to 120°C;

[0034] (2) add stearyl alcohol in cracking kettle;

[0035] (3) After starting the stirrer, add dimethyldichlorosilane hydrolyzate and KOH solution with a mass fraction of 45% into the cracking kettle, the volume ratio of KOH solution and hydrolyzate is 1:1000;

[0036] (4) Heating the reaction kettle, controlling the temperature in the cracking kettle to be 150° C., and the cracking reaction is carried out;

[0037] (5) After cracking reaction for a period of time, when the liquid level of cracking tank rose to 90% of the total volume of cracking tank, the amount of discharge at the bottom was significantly reduced, and the reaction was stopped to replace stearyl alcohol, and continued according to steps (1)-(5) P...

Embodiment 3

[0040] A method for producing cyclic siloxane by catalytic cracking of solvent oil, comprising the following steps:

[0041] (1) First vacuumize the cracking tank, control the pressure to -0.097MPa, and slowly raise the temperature of the cracking tank to 120°C;

[0042] (2) add stearyl alcohol in cracking kettle;

[0043] (3) After starting the stirrer, add dimethyldichlorosilane hydrolyzate and KOH solution with a mass fraction of 45% into the cracking kettle, the volume ratio of KOH solution and hydrolyzate is 1:1000;

[0044] (4) Heating the reaction kettle, controlling the temperature in the cracking kettle to be 130° C., and the cracking reaction is carried out;

[0045] (5) After cracking reaction for a period of time, when the liquid level of cracking tank rose to 90% of the total volume of cracking tank, the amount of discharge at the bottom was significantly reduced, and the reaction was stopped to replace stearyl alcohol, and continued according to steps (1)-(5) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com