Method for preparing modified polycarbonate sub-lactone material

A technology of polylactene carbonate and polypropylene carbonate, which is applied in the field of preparation of modified polylactene carbonate materials, can solve the problems of large consumption, high carbon dioxide emission, inability to form a virtuous cycle, etc., and achieves a good phase. Capacitance and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

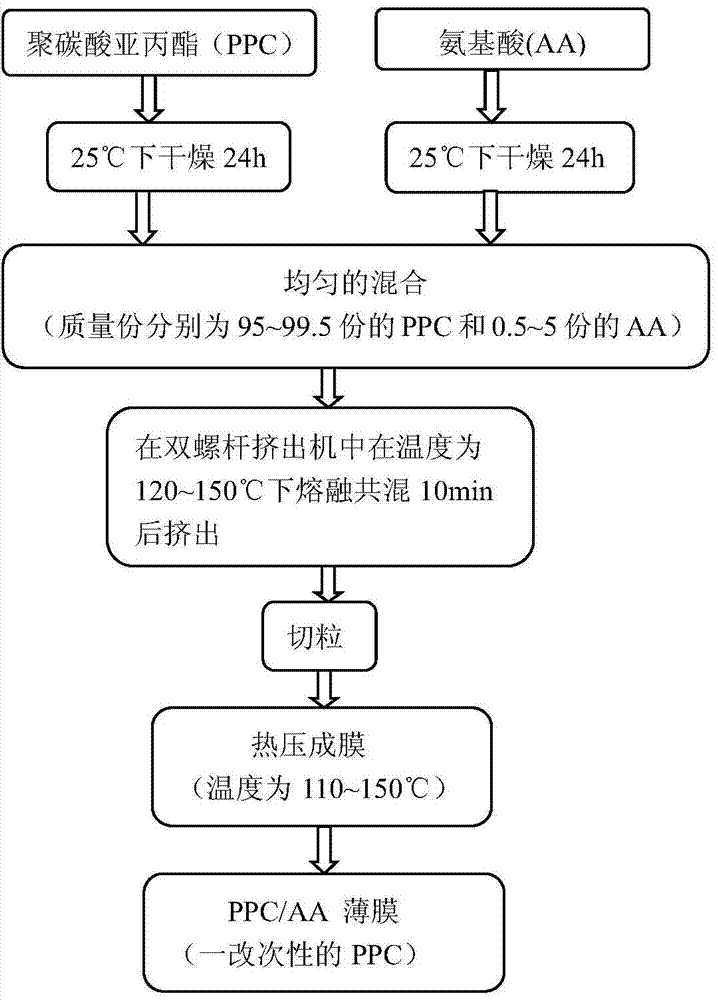

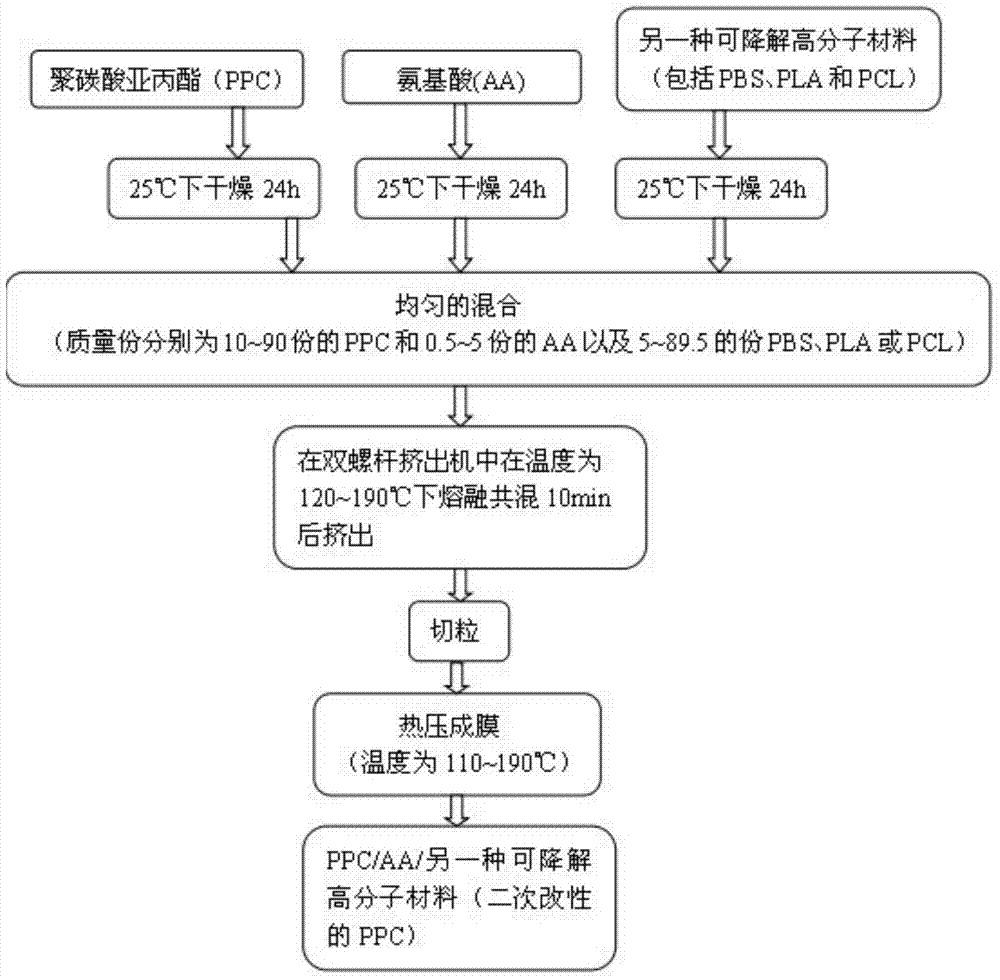

[0043] Such as Figure 1-2 Shown, a kind of preparation method of modified polypropylene carbonate material, the method step is as follows:

[0044] Step 1. Drying of raw materials

[0045] Dry polypropylene carbonate (PPC), amino acid (AA) and another degradable polymer material in a vacuum drying oven for 24 hours at a temperature of 25°C and a vacuum degree of 0.07-0.09 MPa;

[0046] Step 2. One-time blending and extrusion

[0047] According to the number of parts, several parts of PPC and AA are uniformly mixed, and then the mixed raw materials are placed in a twin-screw extruder with a rotation speed of 28r / min, melt-blended at 120-150°C, banburyed for 10 minutes, and then extruded out, and then pelletize the material to obtain a modified PPC / AA composite material;

[0048] Step 3, secondary blending and extrusion

[0049] Mix PPC, AA, and another degradable polymer material uniformly, and then melt and blend the mixed raw materials in a twin-screw extruder at 120-190...

Embodiment 1

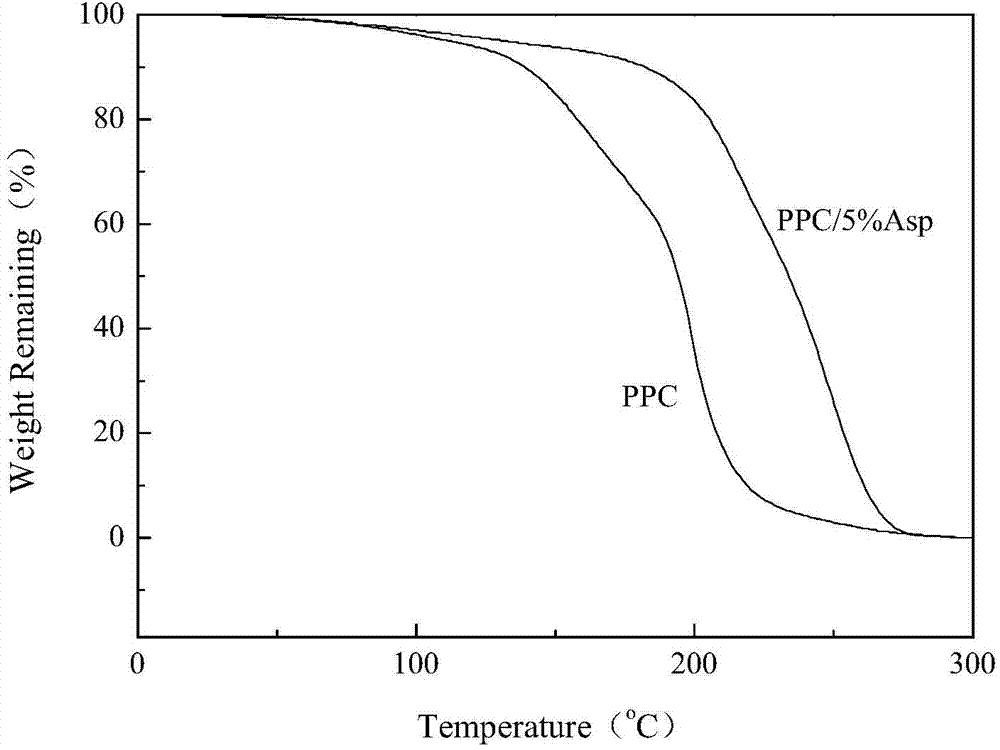

[0060] Embodiment 1: A kind of preparation method of modified polypropylene carbonate material, calculated by weight, first 95 parts of PPC and 5 parts of Asp are uniformly mixed, and then the mixed material is added into a twin-screw extruder Melt blending, banburying and extrusion granulation are carried out at a temperature of 120°C to obtain a modified PPC material, that is, a PPC / Asp composite material. Weigh 3.5 g of the first-time modified composite material, and heat-press it on a hot press at a temperature of 110°C to form a film to obtain a first-time modified polypropylene carbonate composite film;

Embodiment 2

[0061] Example 2: After uniformly mixing 50 parts of PPC, 5 parts of Asp and 45 parts of PBS, they were added to a twin-screw extruder at a temperature of 120°C for melt blending, banburying and extrusion granulation to obtain The secondary modified PPC material is PPC / Asp / PBS composite material. Weigh 3.5 g of the secondary modified composite material, and press it on a hot press at a temperature of 110° C. to form a film to obtain a secondary modified polypropylene carbonate composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com