Method for measuring metallic magnesium content of briquette nodulizing agent by using complexometry

A complexometric titration, metal magnesium technology, which is applied in chemical analysis by titration, material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of long and uniform analysis time. It can solve the problems of poor performance and high activity of metal magnesium powder, which can simplify the analysis steps, shorten the analysis cycle and reduce the cost of testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

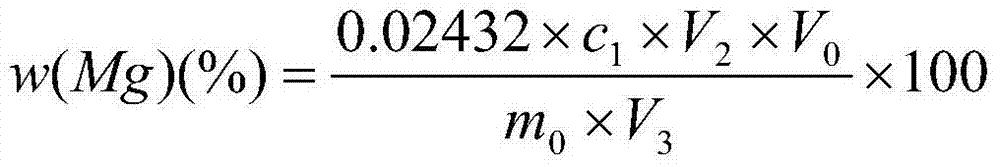

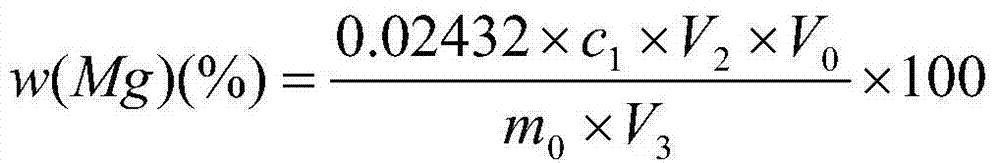

Method used

Image

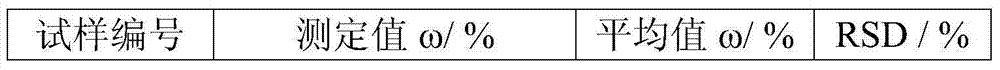

Examples

Embodiment Construction

[0024] Further illustrate technical scheme of the present invention by embodiment below: the assay method of metal magnesium content in the briquetting spheroidizing agent, but content of the present invention is not only limited to following examples:

[0025] (1) Accurately weigh 10g of the nodulizer sample into a 500mL beaker, add (1+9) dilute acetic acid 200mL, shake fully at room temperature for 20min until the metal magnesium is completely dissolved. Use slow filter paper to filter in a 500mL volumetric flask, transfer all the residue to the filter paper, and rinse the beaker and the residue on the filter paper with pure water for 3 to 5 times. Dilute to volume with water, mix well.

[0026] (2) Accurately pipette 20.00 mL of the filtrate into a 250 mL beaker, adjust the pH to 6-7 with ammonia water, add about 80 mL of water, add 10 mL of copper reagent, and mix well. Transfer to a 250mL volumetric flask, dilute to the mark with water, mix well, let stand for 10min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com