Rubimaillin/chitosan nanoparticle, and preparation method and application thereof

A nanotechnology of rubidin and chitosan, which is applied in the field of medicine, can solve the problems of large particle size of drug-loaded microspheres, high reaction conditions, and complicated preparation, and achieve anti-oxidation and inhibition of cancer cell activity with good repeatability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

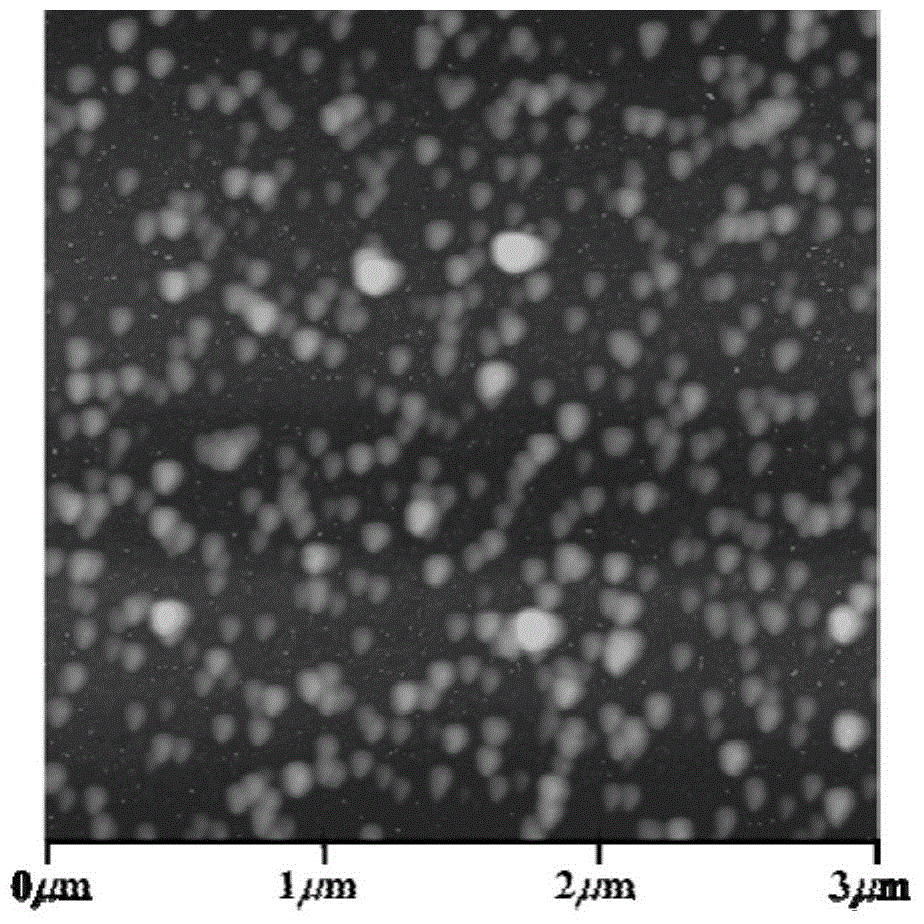

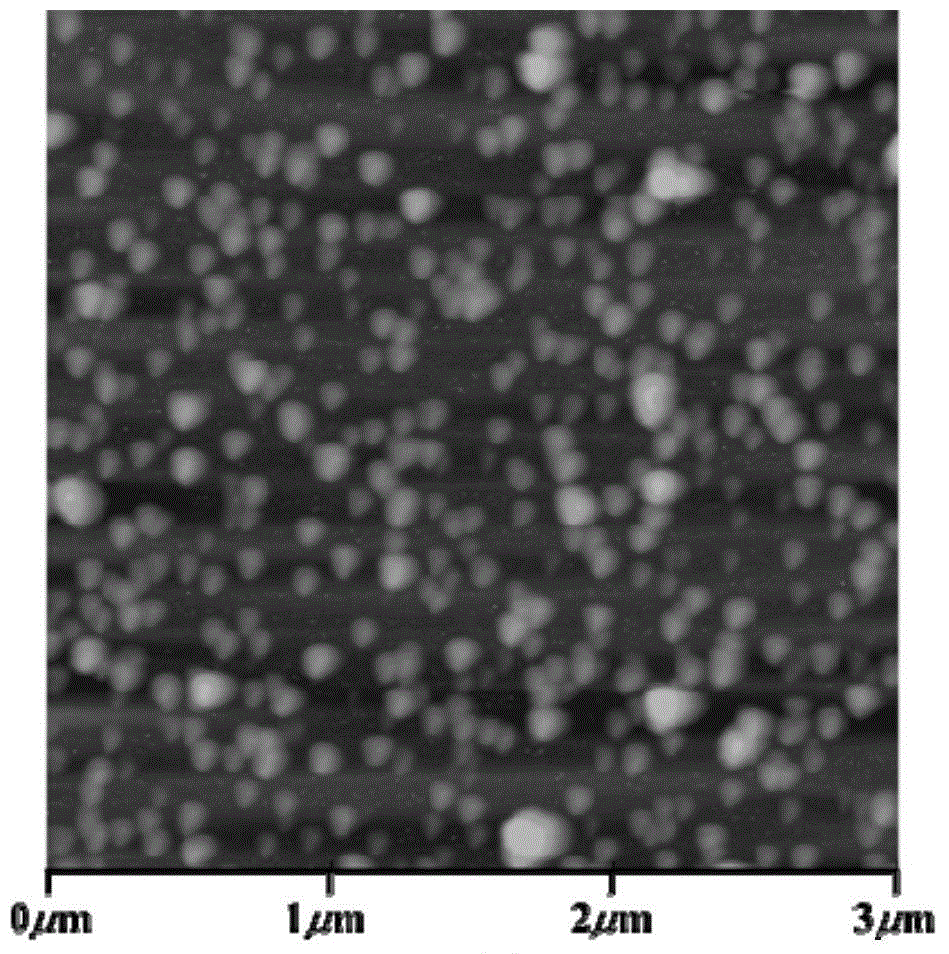

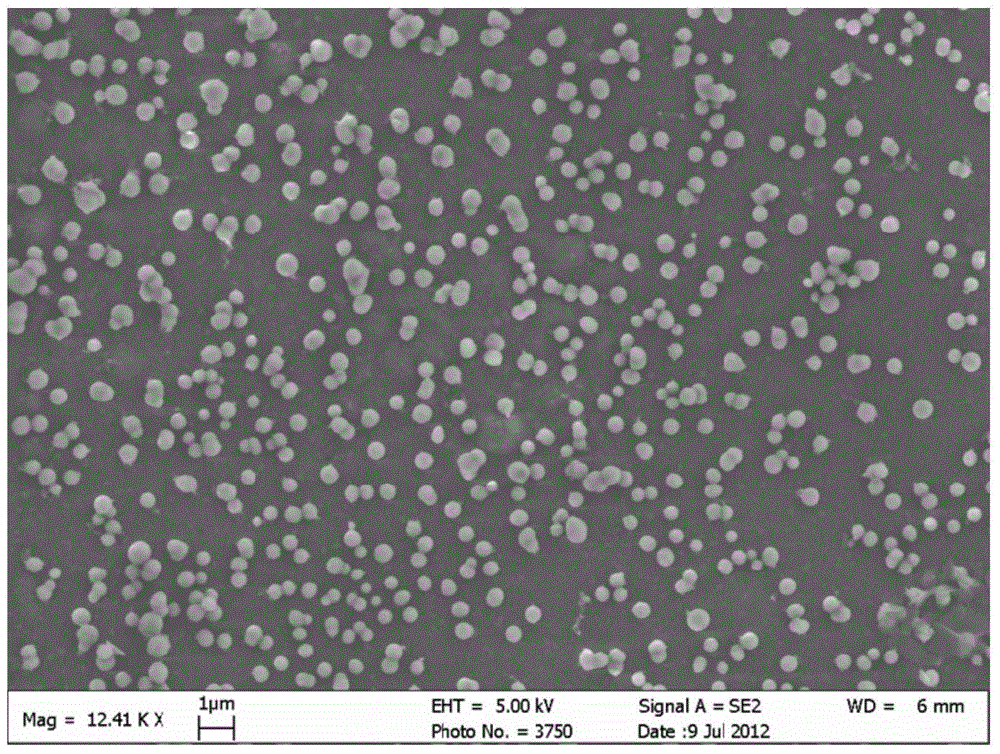

Image

Examples

Embodiment 1

[0026] The preparation method of rubidin / chitosan nano-microspheres of the present embodiment is as follows:

[0027] (1) Dissolve chitosan (deacetylation degree 82%, molecular weight 500,000) in an aqueous solution containing 0.1wt% poloxamer 188 and 1.5% (V / V) acetic acid to form a 1.0mg / mL shell The polysaccharide aqueous solution is then filtered through a microporous membrane with a pore size of 0.45 μm, and the resulting filtrate is adjusted to a pH value of 4.0 by a NaOH solution with a concentration of 1mol / L to obtain a chitosan component liquid;

[0028] (2) Dissolve rubikin in absolute ethanol to form a rubidin ethanol solution with a concentration of 1.0 mg / mL, and filter through a microporous membrane with a pore size of 0.45 μm to obtain the rubikin component liquid ;

[0029] (3) Add 1mL step (2) gained rubidin component liquid dropwise in 5mL step (1) gained chitosan component liquid, fully stir (stirring speed is 800r / min), and dropwise add 2mL1 .0mg / mL sodi...

Embodiment 2

[0033] The preparation method of rubidin / chitosan nano-microspheres of the present embodiment is as follows:

[0034] (1) Dissolve chitosan (deacetylation degree 97%, molecular weight 100,000) in an aqueous solution containing 0.3wt% poloxamer 188 and 1.0% (V / V) acetic acid to form a 1.2mg / mL shell The polysaccharide aqueous solution is then filtered through a microporous membrane with a pore size of 0.45 μm, and the resulting filtrate is adjusted to a pH value of 3.5 by a NaOH solution with a concentration of 1mol / L to obtain a chitosan component liquid;

[0035] (2) Dissolving rubikin in absolute ethanol to form a rubidin ethanol solution with a concentration of 3.0 mg / mL, and filter it through a microporous membrane with a pore size of 0.45 μm to obtain the rubikin component liquid ;

[0036](3) Add 1mL step (2) gained rubidin component liquid dropwise in 5mL step (1) gained chitosan component liquid, fully stir (stirring rate is 1200r / min), and dropwise add 2mL1 .5 mg / mL...

Embodiment 3

[0040] The preparation method of rubidin / chitosan nano-microspheres of the present embodiment is as follows:

[0041] (1) Dissolve chitosan (deacetylation degree 90%, molecular weight 300,000) in an aqueous solution containing 0.5wt% poloxamer 188 and 1.2% (V / V) acetic acid to form a 3.0mg / mL shell The polysaccharide aqueous solution is then filtered through a microporous membrane with a pore size of 0.45 μm, and the resulting filtrate is adjusted to a pH value of 4.5 by a NaOH solution with a concentration of 1mol / L to obtain a chitosan component liquid;

[0042] (2) Dissolving rubikin in absolute ethanol to form a rubidin ethanol solution with a concentration of 5.0 mg / mL, and filter it through a microporous membrane with a pore size of 0.45 μm to obtain the rubikin component liquid ;

[0043] (3) Add 1mL step (2) obtained rubidin component liquid dropwise in 5mL step (1) gained chitosan component liquid, fully stir (stirring speed is 1600r / min), and add dropwise 2mL3 .0 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com