Nickel-titanium alloy containing bioactive coating and its preparation method and application

A nickel-titanium alloy and bioactive technology, applied in the field of preparation of the alloy, can solve the problems that a single bioactive molecule is difficult to simulate the microenvironment outside the endothelial cells, and cannot meet the rapid endothelialization of the material surface, so as to promote adhesion and growth , increase long-term effectiveness, and solve the effect of inducing thrombosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

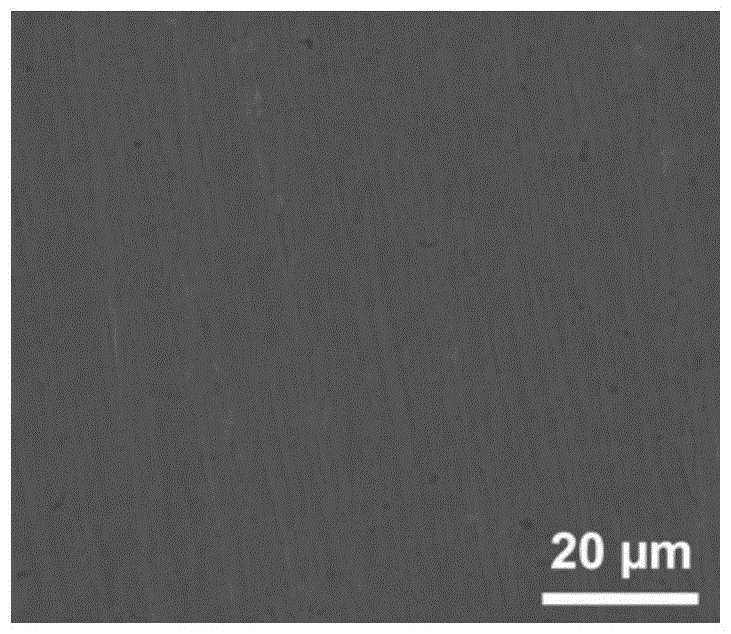

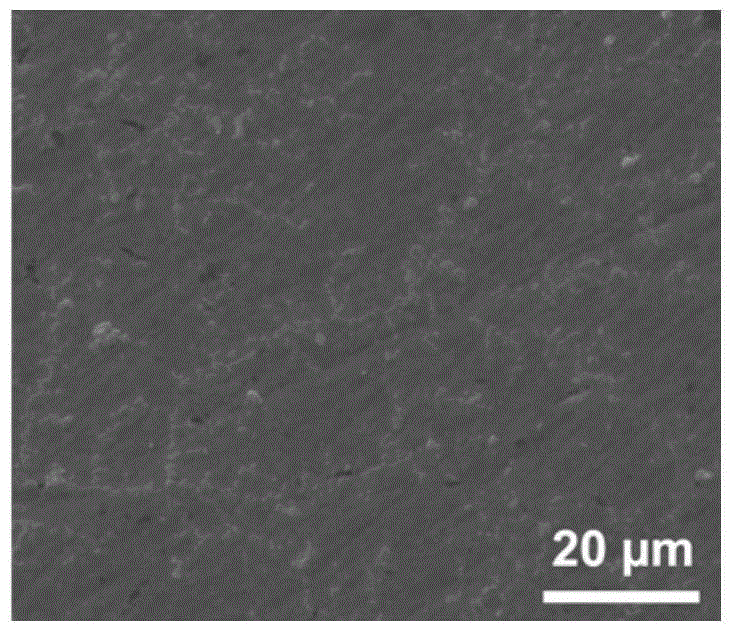

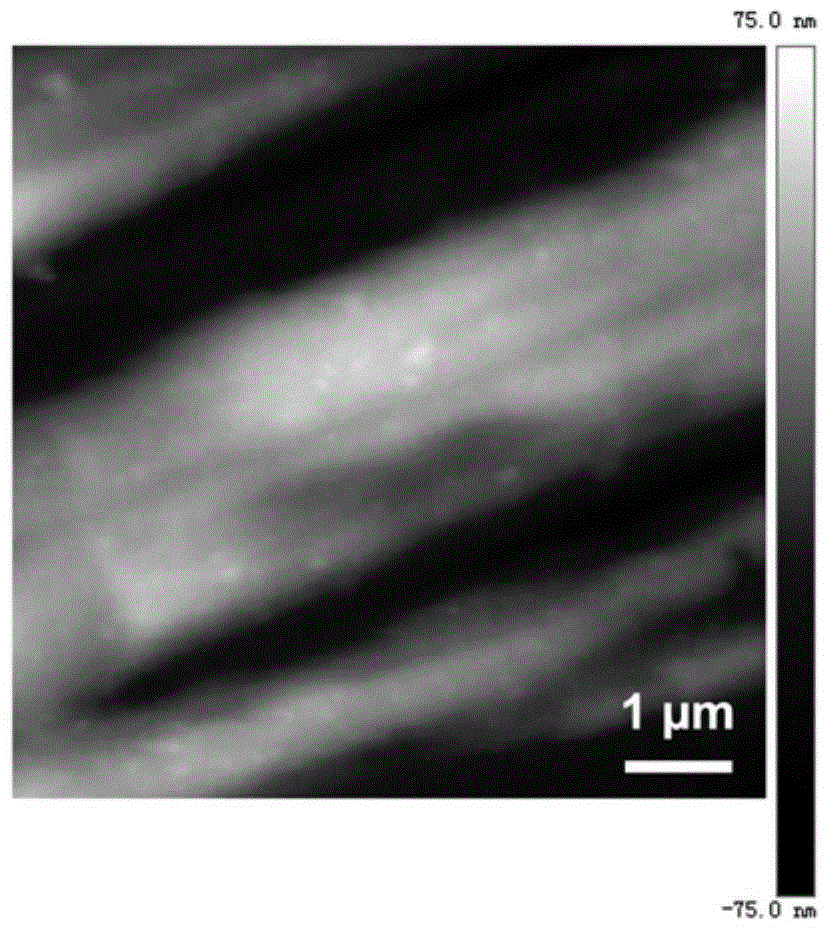

Image

Examples

Embodiment 1

[0028] Take a nickel-titanium alloy sheet and follow the steps below to construct a biologically active coating imitating the extracellular microenvironment:

[0029] (1) Substrate pretreatment

[0030] Polish the nickel-titanium alloy sheet with 100-mesh, 300-mesh and 2000-mesh sandpaper in turn until the surface is bright, and ultrasonically clean it with acetone for 5 minutes to obtain a clean metal surface;

[0031] (2) deposition polydopamine film layer

[0032] With 10mM, the Tris buffer solution that pH value is 8.5 prepares the dopamine hydrochloride solution of 2mg / mL, soaks the nickel-titanium alloy after step (1) treatment in this solution for 24 hours, obtains the nickel-titanium alloy of surface deposition polydopamine film layer ;

[0033] (3) Layer-by-layer self-assembly

[0034] With the acetic acid of 0.3% (v / v) as solvent, prepare the chitosan solution of 5mg / mL; Prepare the gelatin solution of 5mg / mL and the endothelial cell growth factor solution of 200n...

Embodiment 2

[0037] Step (2) of this embodiment uses 20 mM Tris buffer solution with a pH value of 7.2 to prepare a 1 mg / mL dopamine hydrochloride solution, and soaks the nickel-titanium alloy treated in step (1) in the solution for 12 hours to obtain a surface deposited polymer. Nitinol alloy for dopamine film layer;

[0038] Present embodiment step (3) is solvent with the acetic acid of 0.5% (v / v), the chitosan solution of preparation 1mg / mL; The endothelial cell growth factor solution of mL; The nickel-titanium alloy of step (2) deposition polydopamine film layer is soaked in gelatin solution 36 hours, then immerses chitosan solution, gelatin solution, endothelial cell growth factor solution and gelatin solution successively, Soak in each solution for 20 minutes, and wash with ultrapure water for 1 minute after each soak;

[0039] Soak chitosan solution, gelatin solution, endothelial cell growth factor solution and gelatin solution in sequence as a layer-by-layer self-assembly cycle, a...

Embodiment 3

[0042] Step (2) of this embodiment uses 20 mM Tris buffer solution with a pH value of 9 to prepare a 3 mg / mL dopamine hydrochloride solution, and soaks the nickel-titanium alloy treated in step (1) in the solution for 36 hours to obtain a surface deposited polymer. Nitinol alloy for dopamine film layer;

[0043] Present embodiment step (3) present embodiment step (3) is solvent with the acetic acid of 0.5% (v / v), the chitosan solution of preparation 10mg / mL; The gelatin solution of mL and the endothelial cell growth factor solution of 500ng / mL; The nickel-titanium alloy of step (2) deposition polydopamine film layer is immersed in gelatin solution for 12 hours, then immerses chitosan solution, gelatin solution, endothelial cell successively Growth factor solution and gelatin solution, soak in each solution for 5 minutes, wash with ultrapure water for 1 minute after each soak;

[0044] Soak chitosan solution, gelatin solution, endothelial cell growth factor solution and gelati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com