Organic nucleating agent used for ester polymer containing aromatic ring, composition, and preparation method and application thereof

An organic nucleating agent and aromatic ring technology, which is applied in the field of polymer materials and ester polymer materials containing aromatic rings, can solve the problems of large aromatic ring steric hindrance, poor molecular chain flexibility, and slow crystallization rate, and achieve hydrogen bonding Strong effect, good compatibility, effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

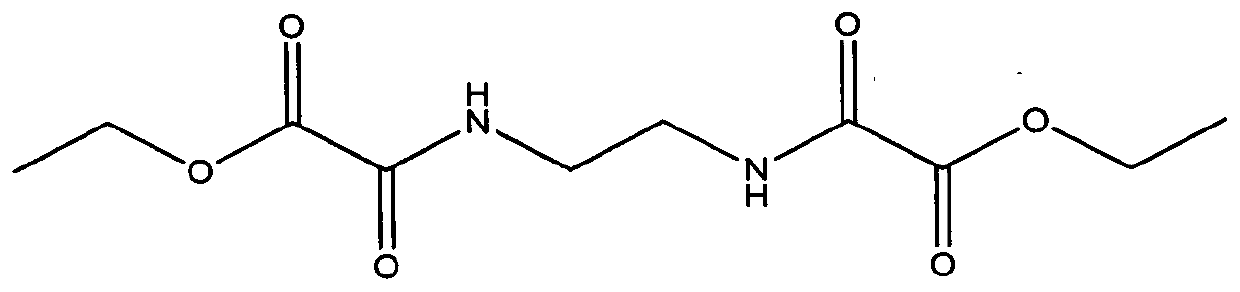

[0051] In a 500ml three-necked flask, add 45g of diethyl oxalate, 300ml of tetrahydrofuran, and 4.1ml of ethylenediamine, react for 16h, filter to obtain a solid component, wash with tetrahydrofuran several times, and then dry in a vacuum oven for 24h to obtain 2,2'-( 1,2-Ethylenediamino)-di(2-acyl ethyl acetate) (hereinafter referred to as "intermediate product"), namely:

[0052]

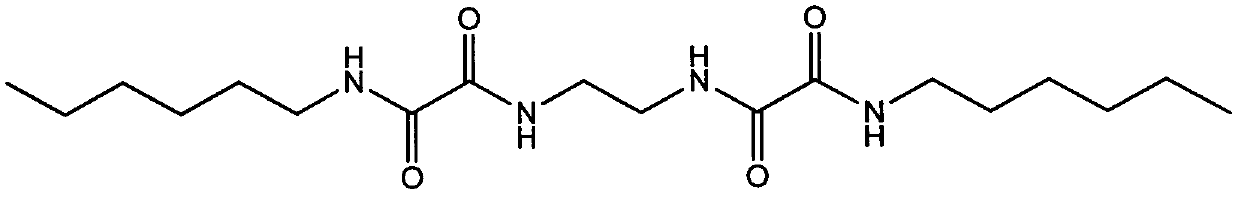

[0053] In a 500ml three-necked flask, add 15.1g of the above-mentioned intermediate product, 16.2ml of n-hexylamine, and 300ml of chloroform, and reflux at 72°C for 48h. The filtered solid is washed with chloroform several times, and then dried in a vacuum oven for 24h to obtain polymer-like organic nucleating agent N 1 , N 1 '-Ethyl-bis-N 2 -Hexyl bisoxamide, namely:

[0054]

Embodiment 2

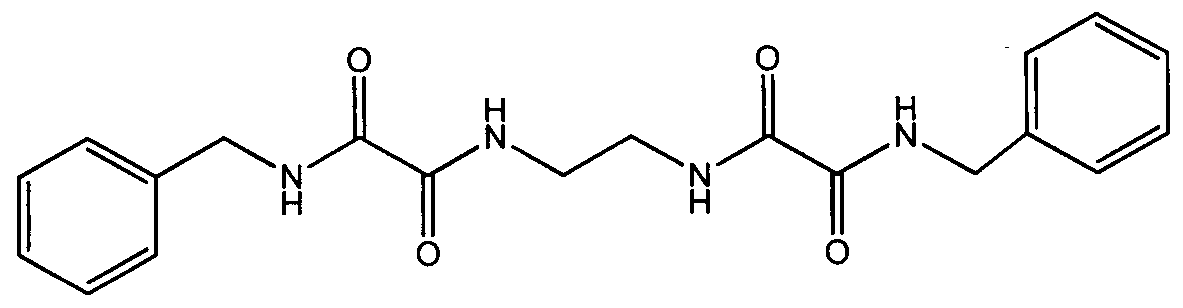

[0056] In a 500ml three-neck flask, add 15.6g of the above-mentioned intermediate product, 14.4ml of benzylamine, and 300ml of chloroform, and reflux at 72°C for 48h. The filtered solid is washed with chloroform several times, and then dried in a vacuum oven for 24h to obtain a Organic nucleating agent for cyclic ester polymers N 1 , N 1 '-Ethyl-bis-N 2 - benzyl bisoxamide, namely:

[0057]

Embodiment 3

[0059] In a 500ml three-neck flask, add 15.2g of the above-mentioned intermediate product, 12.0ml of aniline, and 200ml of chloroform, and reflux at 72°C for 48h. The filtered solid is washed with chloroform several times, and then dried in a vacuum oven for 24h to obtain a Organic nucleating agent N for ester polymers 1 , N 1 '-Ethyl-bis-N 2 -Phenyl bisoxamide, namely:

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com