Spindle oil composition

A technology of composition and spindle oil, which is applied in the direction of lubricating composition, etc., can solve the problems of complex preparation process, low output, supply limitation, etc., and achieve the effect of simple synthesis route, wide source and stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention has no special limitation on the source of the poly-alpha-olefin, just use the poly-alpha-olefin well-known to those skilled in the art, such as the commercially available poly-alpha-olefin that can be used, also can adopt the well-known polyalpha-olefin of those skilled in the art The technical scheme for preparing poly-alpha-olefins is self-prepared. In the present invention, the synthesis route of the poly-α-olefin is simple, and the synthesis conditions are mild; the preparation method of the poly-α-olefin may include the following steps: polymerizing and hydrogenating the α-olefin to obtain poly-α-olefin; α-olefins can be obtained by ethylene oligomerization or paraffin cracking.

[0036] The spindle oil composition provided by the present invention includes 0.1wt%-3wt% of antioxidant, preferably 0.2wt%-2.5wt%, more preferably 0.3wt%-2wt%. In the present invention, the antioxidant preferably includes one or more of organic phenols, amine comp...

Embodiment 1

[0053] 40.45g of polya-olefin, 56g of phthalate, 1.5g of 2,6-di-tert-butylphenol, 0.5g of benzotriazole, 1.5g of dodecenylsuccinate half ester and 0.05g of methyl methacrylate The esters were mixed at 55°C for 30 minutes to obtain a spindle oil composition.

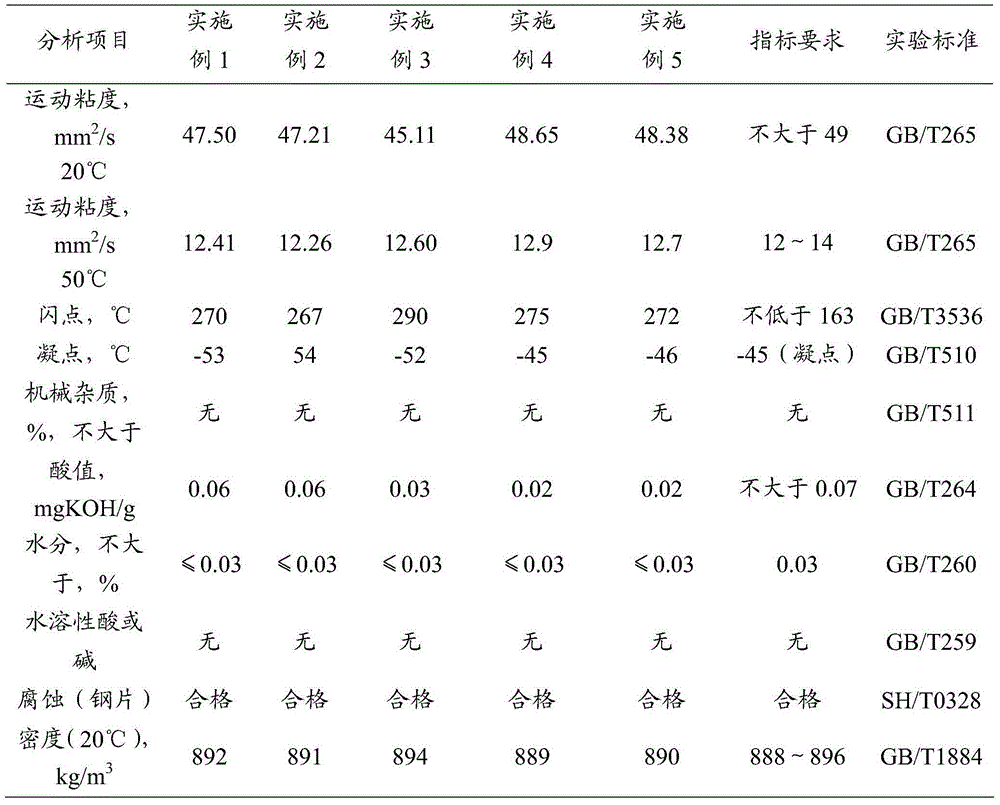

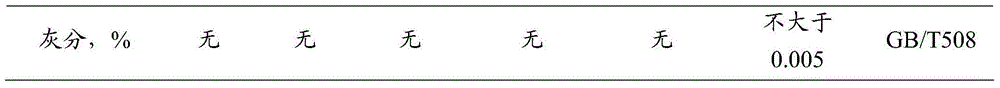

[0054] The present invention performs a performance test on the obtained spindle oil composition according to the test method described in the above technical solution, and the test results are shown in Table 1, and Table 1 shows the performance test results of the lubricating grease composition obtained in Examples 1 to 5 of the present invention .

Embodiment 2

[0056] 40.45g polya-olefin, 56g dioctyl phthalate, 1.5g 4,4'-methylene bis(2,6-di-tert-butylphenol), 0.5g 2,5-dimercapto-1,3 , 4-thiadiazole, 1.5g of petroleum sulfonate and 0.05g of ethyl acrylate were mixed at 60°C for 60min to obtain a spindle oil composition.

[0057] The present invention performs a performance test on the obtained spindle oil composition according to the test method described in the above technical solution, and the test results are shown in Table 1, and Table 1 shows the performance test results of the spindle oil composition obtained in Examples 1 to 5 of the present invention .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com