Preparation method of spherical layer-structured anode material externally coated with nanocrystalline metal oxide for lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, secondary batteries, structural parts, etc., can solve the problems of uneven coating layer distribution, cumbersome process, and cumbersome process, and achieve good product consistency. The effect of simple process flow and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

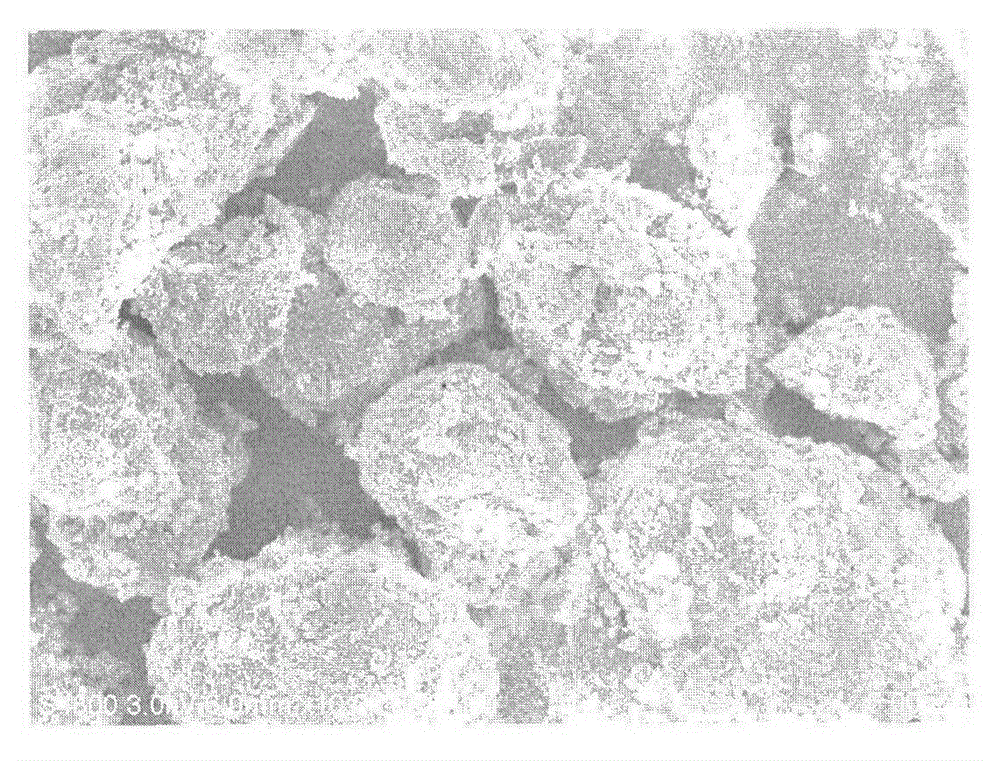

[0040] Example 1 LiCoO coated with 2.0%wt. nanometer titanium dioxide on the surface 2

[0041] Use a little pure water as the bottom liquid, heat the temperature to 40°C, and adjust the rotation speed of the stirrer to 100r / min. Cobalt sulfate solution (0.25mol / L) and Na 2 CO 3 +NH 4 HCO 3 The solution (0.5mol / L) was slowly added dropwise to the continuously stirred reactor, and the pH value of the solution was controlled to be 8.0. A spherical cobalt carbonate precursor is obtained after aging the precipitate, filtering, washing and drying.

[0042] The spherical cobalt carbonate precursor is uniformly ball-milled with lithium hydroxide, calcined at 500°C for 6 hours, ground, pressed into tablets, and then calcined at 800°C for 20 hours to obtain a spherical lithium cobaltate positive electrode material.

[0043] Disperse the prepared spherical lithium cobaltate positive electrode material and stoichiometric nano-titanium dioxide in an appropriate amount of ethanol, an...

Embodiment 2

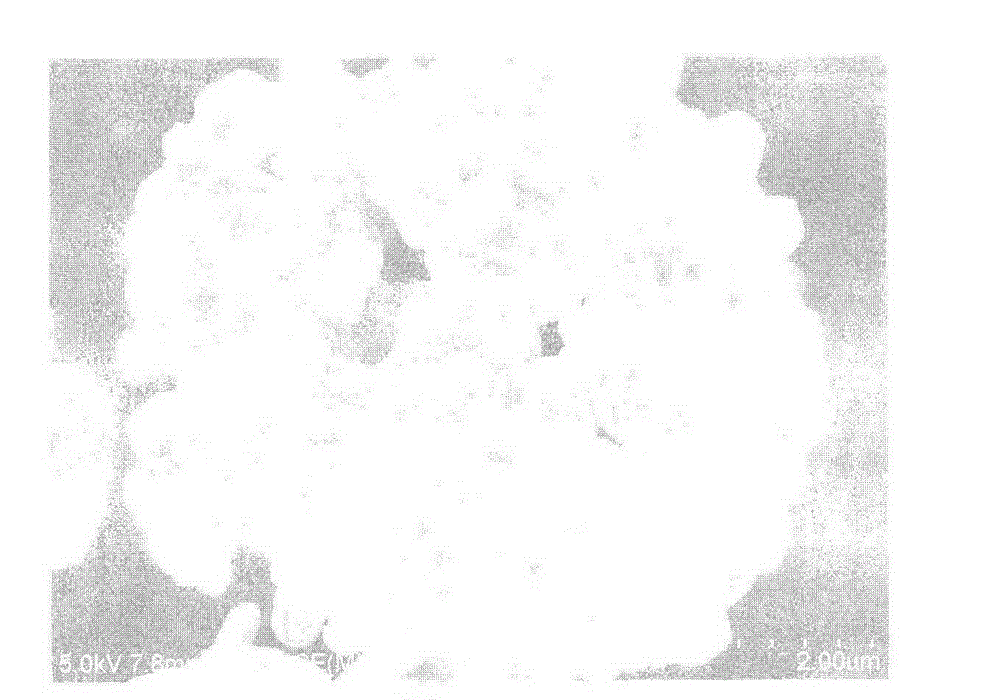

[0044] Example 2 Li(Ni 0.5 mn 0.5 )O 2

[0045]Use a little pure water as the bottom liquid, heat the temperature to 50°C, and adjust the speed of the stirrer to 150r / min. Nickel acetate, manganese acetate mixed salt solution (0.5mol / L) and Na 2 CO 3 +NH 4 HCO 3 The solution (1.0mol / L) was slowly added dropwise to the continuously stirred reactor, and the pH value of the solution was controlled to be 8.5. A spherical nickel-manganese carbonate precursor is obtained after the precipitate is aged, filtered, washed and dried.

[0046] The spherical nickel-manganese carbonate precursor is uniformly ball-milled with lithium carbonate, calcined at 500°C for 6 hours, ground, pressed into tablets, and then calcined at 900°C for 15 hours to obtain a spherical nickel-manganese binary positive electrode material.

[0047] Disperse the prepared spherical nickel-manganese binary positive electrode material and stoichiometric nano-titanium dioxide in an appropriate amount of deioniz...

Embodiment 3

[0049] Example 3 Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2

[0050] Use a little pure water as the bottom liquid, heat the temperature to 60°C, and adjust the rotation speed of the stirrer to 200r / min. Mix nickel sulfate, cobalt sulfate, manganese sulfate mixed salt solution (1.0mol / L) with Na 2 CO 3 +NH 4 HCO 3 The solution (2.0mol / L) was slowly added dropwise into the continuously stirred reactor, and the pH value of the solution was controlled to be 9.0. A spherical nickel-cobalt-manganese carbonate precursor is obtained after the precipitate is aged, filtered, washed and dried.

[0051] The spherical nickel-cobalt-manganese carbonate precursor is uniformly ball-milled with lithium acetate, calcined at 500°C for 6 hours, ground, pressed into tablets, and then calcined at 950°C for 12 hours to obtain a spherical nickel-cobalt-manganese ternary positive electrode material.

[0052] Disperse the prepared spherical nickel-cobalt-manganese ternary positive electrode material and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com