A kind of preparation method of nano silver phosphate photocatalyst

A catalyst and phosphoric acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems of large particle size and low specific surface area, and achieve uniform size distribution, good repeatability, and utilization of visible light strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 0.338g AgNO respectively 3 and 1.768g Na 3 PO 4 12H 2 O, put it in an agate mortar and grind for 0.5 hours to get a uniformly distributed mixed powder; put the mixed powder into a polytetrafluoroethylene reaction vessel, heat up to 180°C in an oven, heat for 24 hours, and wait to cool to room temperature Finally, take out the sample and dissolve it in hot deionized water, then centrifuge the resulting mixture, and wash it twice with deionized water and three times with ethanol; put the obtained sample in a drying oven at 60°C for 12 hours, and then Ag after furnace cooling and grinding 3 PO 4 catalyst of light.

Embodiment 2

[0024] Weigh 0.338g AgNO respectively 3 and 3.536g Na 3 PO 4 12H 2 O, put it into an agate mortar and grind for 0.5 hours to get a uniformly distributed mixed powder; put the mixed powder into a polytetrafluoroethylene reaction vessel, heat up to 120°C in an oven, heat for 12 hours, and wait to cool to room temperature Finally, take out the sample and dissolve it in hot deionized water, then centrifuge the resulting mixture, and wash it twice with deionized water and three times with ethanol; put the obtained sample in a drying oven at 60°C for 12 hours, and then Ag after furnace cooling and grinding 3 PO 4 catalyst of light.

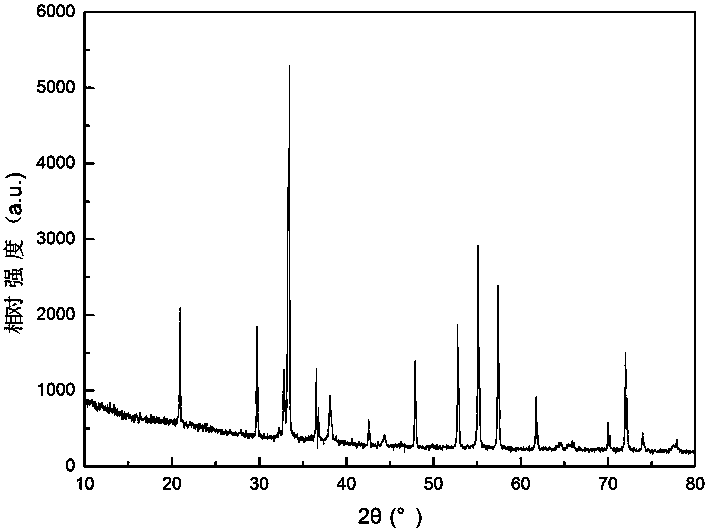

[0025] See attached figure 1 , which is the Ag prepared in this example 3 PO 4 The XRD diffraction pattern of the photocatalyst, from figure 1 It can be seen that the intensity of the diffraction peak is high and sharp, indicating that the synthesized Ag 3 PO 4 Good crystallinity.

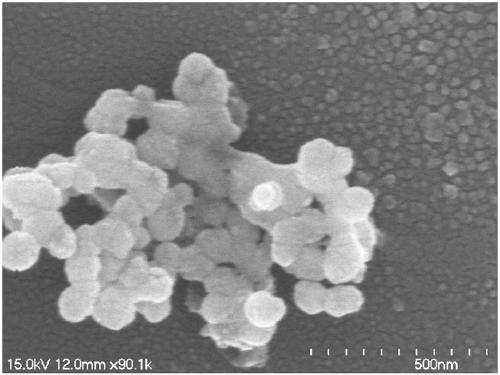

[0026] See attached figure 2 , which is the Ag prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com