A method of cleaning membrane

A technology of cleaning guns and high-pressure cleaners, applied in the field of cleaning membranes, can solve the problems of microbial influence, secondary pollution, complicated operation, etc., and achieve the effects of good protection, low labor intensity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A school’s domestic wastewater is treated by JDL membrane technology processor, the scale is 100t / d, the membrane module is hollow fiber membrane, the membrane pressure before cleaning is -0.02MPa, and the flux is 3.5m 3 / h.

[0021] Adopt the method of the present invention to directly clean the membrane surface in water, and the specific implementation method is:

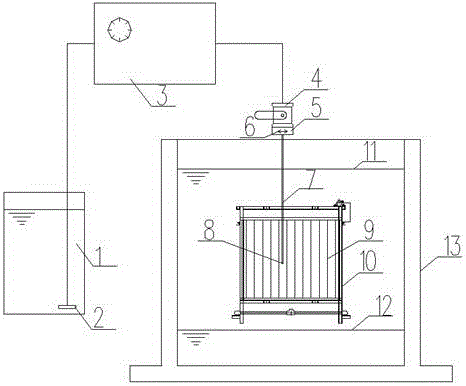

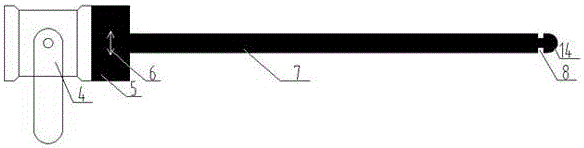

[0022] Stop the JDL membrane technology processor, open the drain valve, close the drain valve when the liquid level reaches 5 cm above the membrane module (9), and do not disassemble the membrane module. The water produced by the JDL membrane technology processor enters the cleaning liquid barrel (1), and is pressurized by the high-pressure cleaner (3) to reach 3MPa. The high-pressure cleaner (3) is connected to the cleaning gun. The cleaning gun is made of stainless steel and has a length of 1.5 meters. , the outlet (8) is a two-way width of 1.0 mm and a length of 5 mm symmetrical gap, the gun rod (7) of...

Embodiment 2

[0024] The domestic wastewater of a hotel is treated by JDL membrane technology processor, the scale is 200t / d, the membrane modules are hollow fiber membranes, the membrane pressure before cleaning is -0.03Mpa, and the flux is 6m 3 / h.

[0025] Adopt the inventive method to directly clean the membrane surface, and the specific implementation method is:

[0026] Stop the JDL membrane technology processor, let it stand for 10 minutes, open the drain valve, the supernatant will flow out through the drain valve, close the drain valve when the liquid level is below the membrane module (9), and do not disassemble the membrane module. The sodium hypochlorite medicinal solution with a mass concentration of one thousandth in the cleaning solution barrel (1) is pressurized by the high-pressure cleaner (3), and the pressure reaches 1 MPa. The high-pressure cleaner (3) is connected to the cleaning gun, and the material of the cleaning gun is stainless steel. , the length is 2.5 meters, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com