Intermediates for the preparation of new oledithiols, their synthesis methods, intermediates and uses

A technology for sodium disulfide and a compound is applied in the field of preparing Xinmulan dithiol, which can solve the problems of limited druggability and limited quantity, and achieve the effects of novel synthesis route, simple operation and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

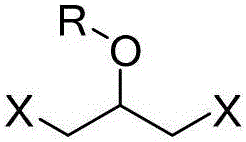

[0048] Embodiment 1: Synthesis of 1,3-dibromo-2-propanol (compound of formula IV)

[0049] Add 20 grams of epibromopropane (compound of formula V) into a three-necked bottle with a thermometer, cool down to below 0°C, slowly add 32 grams of hydrobromic acid (40%) dropwise, during the process of violent heat release, control the temperature below 5°C, after the addition was complete, keep stirring at 0°C for 4 hours, extract twice with ether, combine the organic phases, wash the organic phase with saturated aqueous sodium bicarbonate solution, and then wash the organic phase with water, dry the organic phase with anhydrous magnesium sulfate, filter and evaporate under reduced pressure The solvent was removed to obtain 27 g of a colorless oil (compound of formula IV), yield: 85%.

[0050] 1 H NMR (400MHz, CDCl 3 ): δ4.00(m,1H), 3.58(d,1H), 3.56(d,1H), 2.6(br,1H).

Embodiment 2

[0051] Example 2: Synthesis of 2-(1,3-dibromo-2-propoxy)-tetrahydropyran (compound of formula III)

[0052]1.09 g of 1,3-dibromo-2-propanol (compound of formula IV) was dissolved in 10 ml of tetrahydrofuran, then 0.84 g of 3,4-dihydropyran was added, followed by 125 mg of pyridine p-toluenesulfonate , stirred at room temperature for 2 hours, added 30 milliliters of ethyl acetate for dilution, washed twice with 30 milliliters of water, and then washed with 30 milliliters of saturated brine, the organic phase was dried over anhydrous sodium sulfate, concentrated by filtration, and the residue was washed with petroleum ether: ethyl acetate The ester (volume ratio 100:1) was used as the eluent, and 1.20 g of a colorless oil (compound of formula III) was obtained by silica gel column chromatography, with a yield of 80%.

[0053] 1 H NMR (400MHz, CDCl 3 ): δ4.76-4.79 (m, 1H), 3.88-4.04 (m, 2H), 3.51-3.71 (m, 5H), 1.53-1.87 (m, 6H).

Embodiment 3

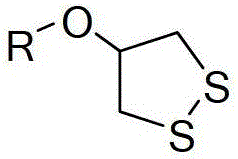

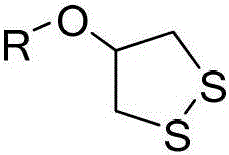

[0054] Embodiment 3: the synthesis of formula II compound

[0055] Dissolve 2.85 grams of sodium sulfide nonahydrate in 10 milliliters of water, add 380 milligrams of sulfur powder, heat to 50 ° C, and wait until the sulfur powder is completely dissolved in the solution to obtain a light yellow solution, cool to room temperature, add this solution to the dissolved 1.20 grams In the chloroform solution of 30 milliliters of the compound of formula III, add a small amount of phase-transfer catalyst tetrabutylammonium bromide, the solution turns black, stir at room temperature for 12 hours, add 20 milliliters of water, separate layers, extract the aqueous layer with chloroform, combine the organic phases, Dry over anhydrous magnesium sulfate, filter, concentrate, and the residue uses petroleum ether:ethyl acetate (volume ratio 200:1) as the eluent, and obtains 500 mg of a colorless oil (compound of formula II) through silica gel column chromatography, Yield 61%.

[0056] 1 H NMR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com