Preparation method of salt-tolerant cellulose super absorbent polymer (SAP)

A technology of water-absorbent resin and carboxymethyl cellulose, which is applied in the field of preparation of water-absorbent resin, and can solve problems such as poor temperature resistance, high price, and single raw material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

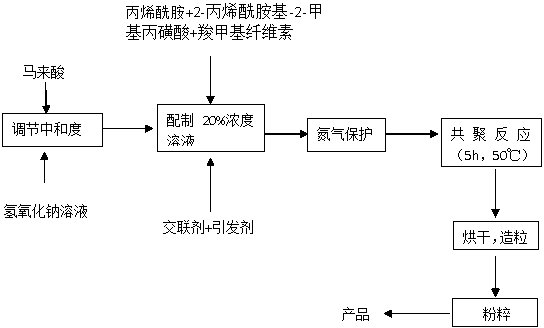

Image

Examples

Embodiment Construction

[0013] The present invention is further described and illustrated below through specific embodiments:

[0014] Weigh 3g maleic acid to prepare a solution, add 25% NaOH solution to adjust the neutralization degree (N) of maleic acid to 80%; weigh 1g carboxymethyl cellulose and swell it; accurately weigh 5g acrylamide, 1g 2-acrylamido-2-methylpropanesulfonic acid was placed in a 250mL three-necked flask, and distilled water was added to stir well to disperse evenly; the above-mentioned monomer was poured into a 250ml three-necked flask, and a certain amount of distilled water was added to make w(CMC+ MA+AM+AMPS)=20% (based on the mass of the system); then add 0.1% mass fraction of cross-linking agent N,N'-methylenebisacryloyl solution, heat up to 50°C; at a speed of less than or equal to 100rpm After stirring for 10 minutes, add dropwise an initiator mass fraction of 0.2% ammonium persulfate-sodium bisulfite solution, and continue stirring until the mixture is uniform; nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com