Organosilicone composite with main chain containing alkylene group structure and preparation method of organosilicone composite

A technology based on alkylene and silicone, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of good thermal shock resistance, excellent heat resistance, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

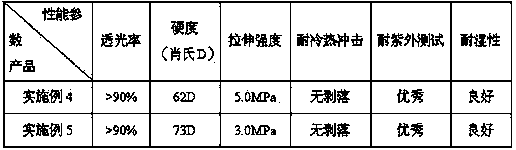

Examples

Embodiment 1

[0060] The preparation of embodiment 1 A1 component

[0061] (1) Add 120g (0.43mol) of 1,4-bis(dimethylethoxysilyl)benzene, diphenyl 150g (0.61mol) of dimethoxysilane, 50g (0.42mol) of dimethyldimethoxysilane, 2,5-bis(dimethylethoxysilyl)bicyclo[2.2.1]-heptane Alkane 40g (0.13mol), vinylmethyldimethoxysilane 5g (0.038mol), vinyldimethylmethoxysilane 20g (0.17mol) and cyclohexane 1000g, stir well and heat it to 70 ℃;

[0062] (2) At 70°C, add 700g of NaOH and water mixture dropwise, and the dropping time is controlled within 1 hour;

[0063] (3) After the dropwise addition, the temperature was raised and refluxed for 5 hours;

[0064] (4) Separate the water layer, and wash the polymer and solvent part with water until neutral;

[0065] (5) After removing unreacted raw materials and solvent, the target product A1 component is obtained.

Embodiment 2

[0066] The preparation of embodiment 2 A2 component

[0067] (1) Add 200g (0.82mol) of diphenyldimethoxysilane and 60g (0.5mol) of dimethyldimethoxysilane into a 5L four-neck flask equipped with a stirrer, condenser, thermometer and constant pressure funnel ), 2,5-bis(dimethylethoxysilyl) bicyclo[2.2.1]-heptane 50g (0.17mol), vinylmethyldimethoxysilane 6g (0.045mol), ethylene 27g (0.23mol) of dimethylmethoxysilane and 1000g of cyclohexane, stir well and raise the temperature to 70°C;

[0068] (2) At 70°C, add 600g of NaOH and water mixture dropwise, and the dropping time is controlled within 1 hour;

[0069] (3) After the dropwise addition, the temperature was raised and refluxed for 5 hours;

[0070] (4) Separate the water layer, and wash the polymer and solvent part with water until neutral;

[0071] (5) After removing unreacted raw materials and solvents, the target product A2 component is obtained.

Embodiment 3

[0072] The preparation of embodiment 3 B component

[0073] (1) Add 2,5-bis(dimethylethoxysilyl)bicyclo[2.2.1]-heptane into a 5L four-necked flask equipped with a stirrer, condenser, thermometer and constant pressure funnel 40g (0.19mol), 250g (1.15mol) of diphenyldimethoxysilane, 80g (0.67mol) of dimethyldimethoxysilane, 20g (0.15mol) of dihydrotetramethyldisiloxane and Cyclohexane 1000g, stir well and heat it up to 50°C;

[0074] (2) At 50°C, add 700 g of a mixture of trifluoromethanesulfonic acid and water dropwise, and the dropping time is controlled within 1 hour;

[0075] (3) After the dropwise addition, the temperature was raised and refluxed for 4 hours;

[0076] (4) Separate the water layer, and wash the polymer and solvent part with water until neutral;

[0077] (5) After removing unreacted raw materials and solvents, the target product, component B, is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com