Biosensor sensitive membrane and application in detection of clenbuterol hydrochloride

A clenbuterol hydrochloride and biosensor technology, applied in the field of biosensors, can solve problems such as difficult implementation of the method, and achieve the effects of easy analysis, reasonable design, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

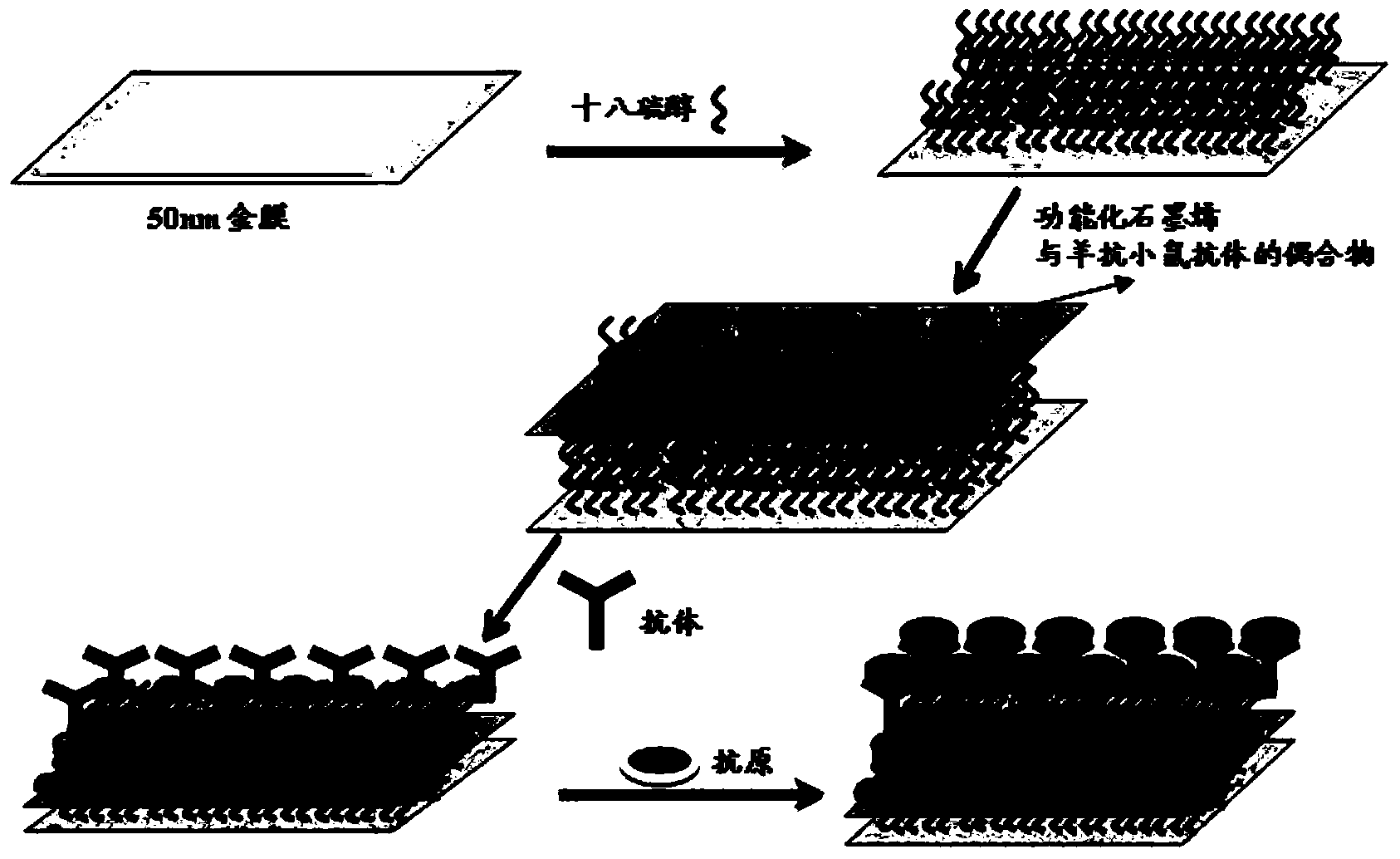

[0056] The biosensor sensitive membrane of the present embodiment, such as figure 1 shown, was prepared by the following method:

[0057] 1) Preparation of gold film: put a 2×2cm glass substrate in a vacuum evaporation machine, and use a vacuum pump to evacuate the vacuum to make the vacuum in the coating chamber reach 1.3×10 -2 Pa, heating the crucible to melt the high-purity gold wire at a temperature of 1400°C and evaporate it into gaseous gold. The gaseous gold particles are deposited on the surface of the moving glass substrate, and a continuous and bright layer is formed on the glass substrate after cooling and reduction. Gold film, the thickness of the gold film is 47-50nm;

[0058] 2) Pretreatment of the gold film loaded on the glass substrate: put the gold film loaded on the glass substrate into H 2 o 2 Soak in a mixed solution with a volume ratio of 3:7 to concentrated sulfuric acid (98% by mass) for 2 minutes, take it out, wash it with ethanol and deionized water...

Embodiment 2

[0082] The biosensor sensitive film of this embodiment is prepared by the following method:

[0083] 1) Preparation of gold film: put a 2×2cm glass substrate in a vacuum evaporation machine, and use a vacuum pump to evacuate the vacuum to make the vacuum in the coating chamber reach 1.3×10 -3 Pa, heating the crucible to melt the high-purity gold wire at a temperature of 1200°C and evaporate it into gaseous gold. The gaseous gold particles are deposited on the surface of the moving glass substrate, and a continuous and bright layer is formed on the glass substrate after cooling and reduction. Gold film, the thickness of the gold film is 47-50nm;

[0084] 2) Pretreatment of the gold film loaded on the glass substrate: put the gold film loaded on the glass substrate into H 2 o 2 Soak in a mixed solution with a volume ratio of 3:7 to concentrated sulfuric acid (mass concentration: 98%) for 4 minutes, take it out, wash it with ethanol and deionized water in turn, dry it for later...

Embodiment 3

[0108] The biosensor sensitive film of this embodiment is prepared by the following method:

[0109] 1) Preparation of gold film: put a 2×2cm glass substrate in a vacuum evaporation machine, and use a vacuum pump to evacuate the vacuum to make the vacuum in the coating chamber reach 1.3×10 -2 Pa, heating the crucible to melt the high-purity gold wire at a temperature of 1400°C and evaporate it into gaseous gold. The gaseous gold particles are deposited on the surface of the moving glass substrate, and a continuous and bright layer is formed on the glass substrate after cooling and reduction. Gold film, the thickness of the gold film is 47-50nm;

[0110] 2) Pretreatment of the gold film loaded on the glass substrate: put the gold film loaded on the glass substrate into H 2 o 2 Soak in a mixed solution with a volume ratio of 3:7 to concentrated sulfuric acid (98% by mass) for 2 minutes, take it out, wash it with ethanol and deionized water in turn, dry it for later use, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com