Application of graphene-nanometer metal oxide composite material in lithium sulfur battery

A nano-metal and composite material technology, applied in lithium batteries, battery electrodes, nanotechnology, etc., can solve the problems of poor battery cycle, easy to produce shuttle effect, poor electronic and ionic conductivity of elemental sulfur, etc., to improve electrical conductivity. stability, convenience, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

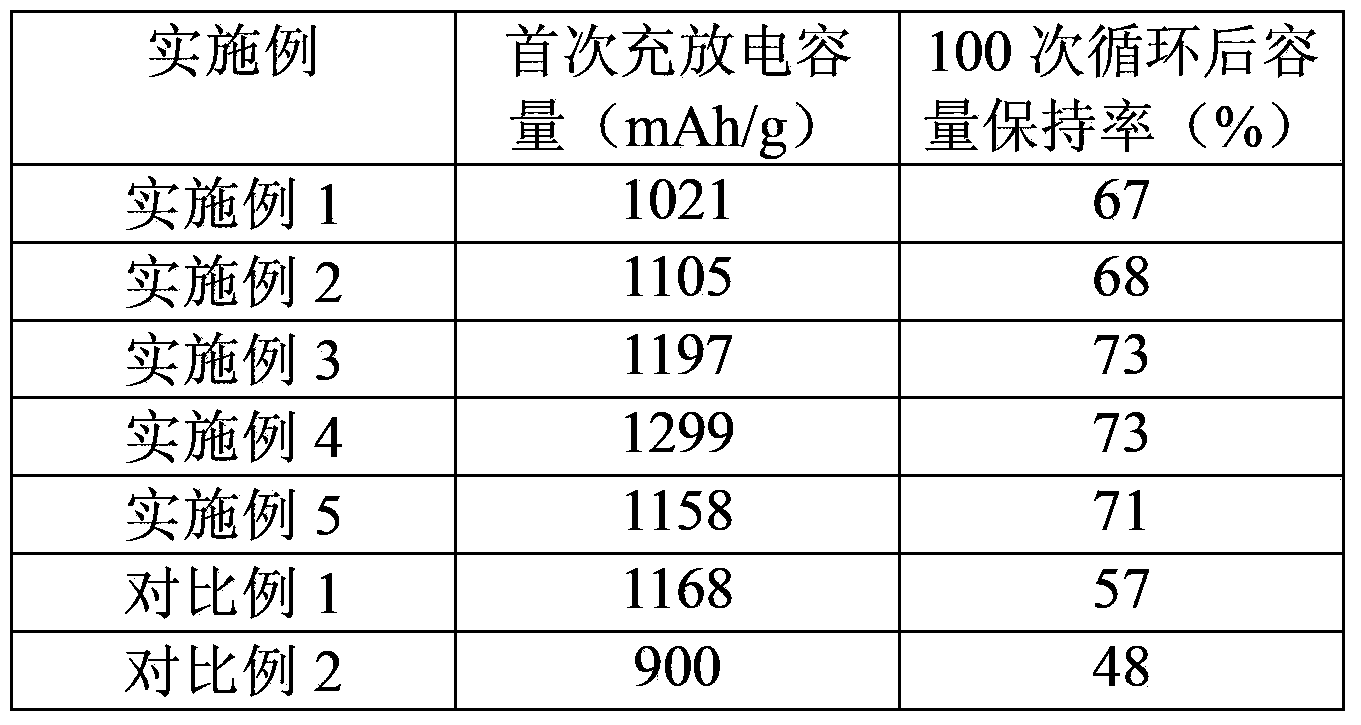

Examples

Embodiment 1

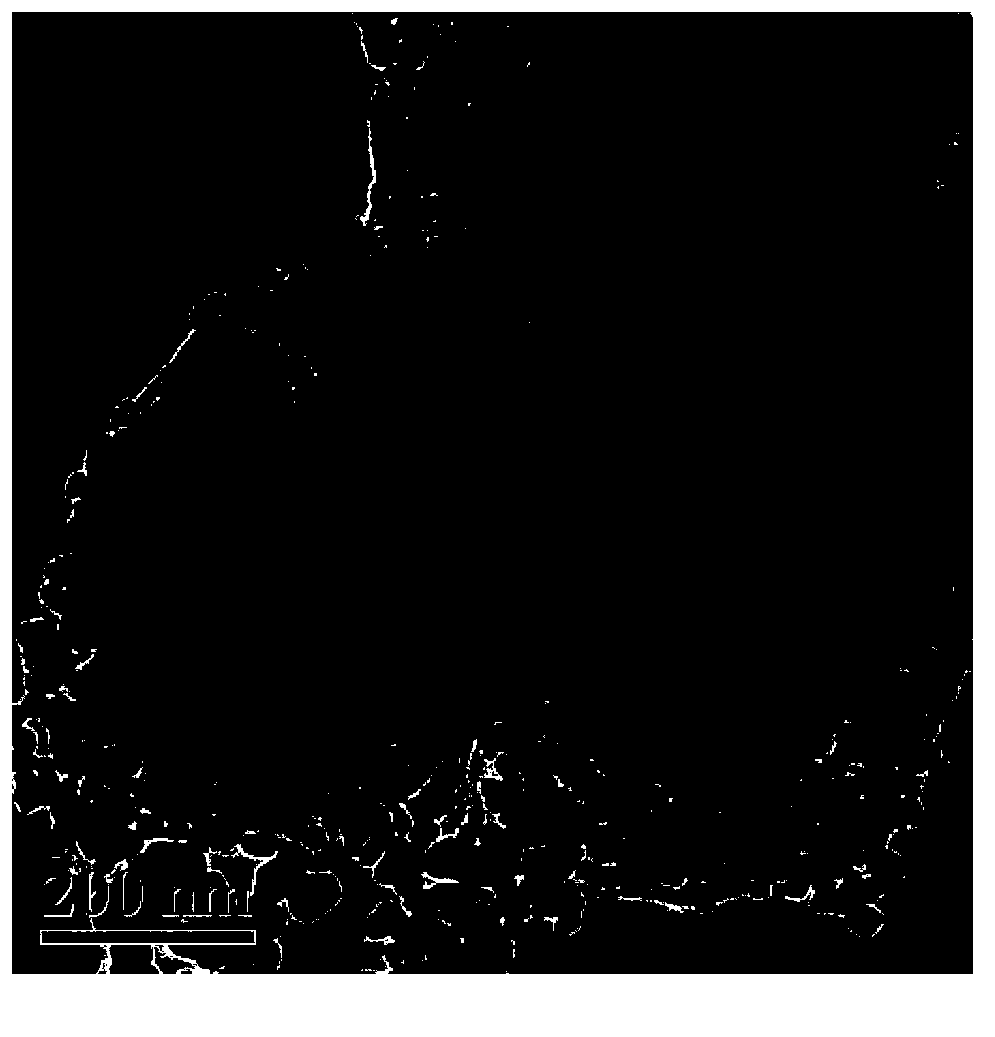

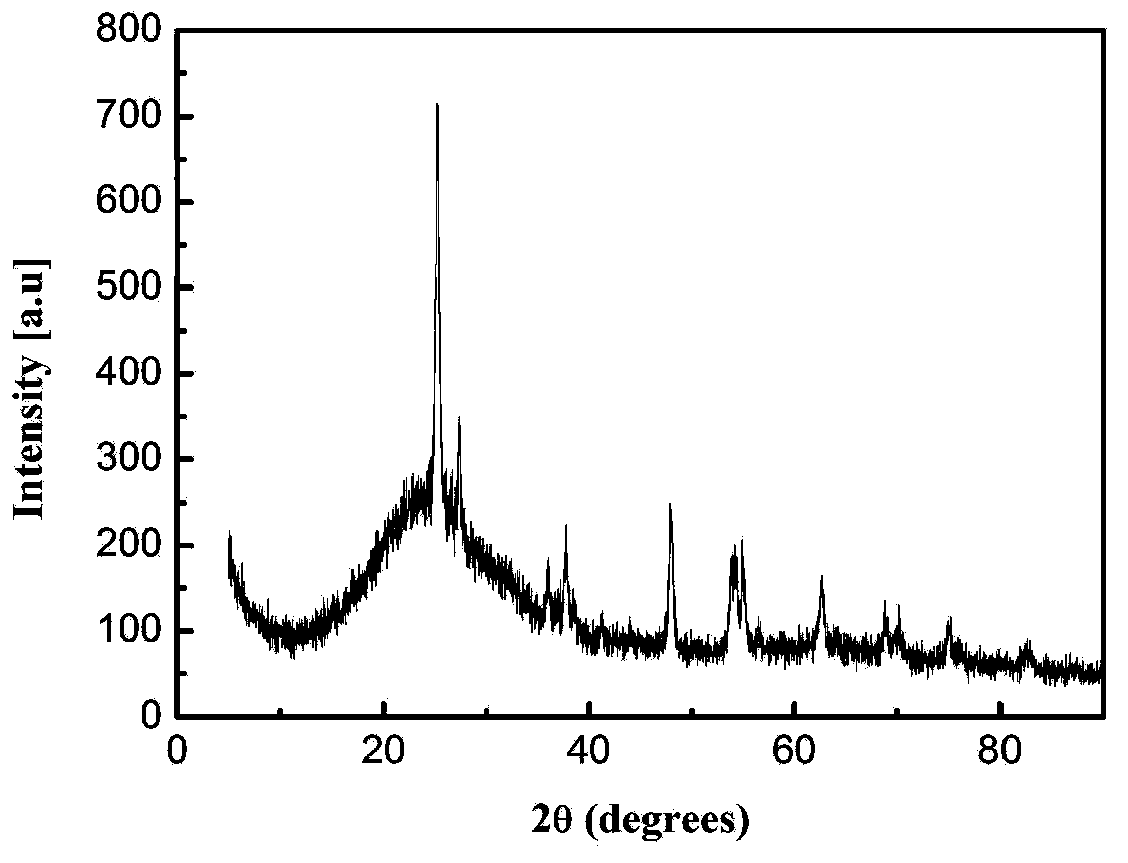

[0029] a. Disperse 0.04 g of graphene oxide ultrasonically in 50 ml of absolute ethanol solution.

[0030] b will 0.1g nano TiO 2 Add the graphene oxide aqueous solution and mix and stir for 3 hours to obtain a graphene oxide-nano metal oxide composite material suspension.

[0031] c Under ultraviolet light irradiation, continue to stir the suspension to reduce the graphene oxide-nano metal oxide composite material to obtain a reduced graphene oxide-nano metal oxide composite material suspension.

[0032] d The suspension is centrifuged and washed with deionized water for 5 times, and the sample is freeze-dried to obtain a reduced graphene oxide-nano metal oxide composite material.

[0033] e Nanofiber vulcanization: Place the prepared reduced graphene oxide-nano metal oxide composite material and elemental sulfur on both ends of the glass tube, and then put the glass tube into a tube furnace, and pass inert gas. Heating at 400°C for 2 hours to prepare a sulfur-graphene-nano metal oxi...

Embodiment 2

[0042] a. Disperse 0.04 g of graphene oxide ultrasonically in 50 ml of absolute ethanol solution.

[0043] b 0.2g nano TiO 2 Add the graphene oxide aqueous solution and mix and stir for 3 hours to obtain a graphene oxide-nano metal oxide composite material suspension.

[0044] c Under ultraviolet light irradiation, continue to stir the suspension to reduce the graphene oxide-nano metal oxide composite material

[0045] Material to obtain a reduced graphene oxide-nano metal oxide composite material suspension.

[0046] d The suspension is centrifuged and washed with deionized water for 5 times, and the sample is freeze-dried to obtain a reduced graphene oxide-nano metal oxide composite material.

[0047] e Nanofiber vulcanization: Place the prepared reduced graphene oxide-nano metal oxide composite material and elemental sulfur on both ends of the glass tube, and then put the glass tube into a tube furnace, and pass inert gas. Heating at 400°C for 2 hours to prepare a sulfur-graphene-na...

Embodiment 3

[0056] a. Disperse 0.04 g of graphene oxide ultrasonically in 50 ml of absolute ethanol solution.

[0057] b 0.3g nano TiO 2 Add the graphene oxide aqueous solution and mix and stir for 3 hours to obtain a graphene oxide-nano metal oxide composite material suspension.

[0058] c Under ultraviolet light irradiation, continue to stir the suspension to reduce the graphene oxide-nano metal oxide composite material

[0059] Material to obtain a reduced graphene oxide-nano metal oxide composite material suspension.

[0060] d The suspension is centrifuged and washed with deionized water for 5 times, and the sample is freeze-dried to obtain a reduced graphene oxide-nano metal oxide composite material.

[0061] e Nanofiber vulcanization: Place the prepared reduced graphene oxide-nano metal oxide composite material and elemental sulfur on both ends of the glass tube, and then put the glass tube into a tube furnace, and pass inert gas. Heating at 400°C for 2 hours to prepare a sulfur-graphene-na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com