A conductive lithium-conducting bifunctional graphene oxide material and its preparation method and application in lithium-sulfur or lithium-air batteries

A graphene, dual-function technology, applied in the field of lithium battery preparation, can solve the problems of poor cycle performance and low capacity, and achieve the effects of reducing battery polarization, improving cycle life and speeding up reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of bifunctional graphene oxide / sulfur composite cathode materials with conductive lithium and conductive components:

[0039] Preparation of composite material: Weigh 1g of flake graphite and place it in a 250mL round bottom flask, add 100mL of concentrated sulfuric acid (≧98%) and 13.3mL of concentrated phosphoric acid (≧85%), stir at 50°C at 500r / min for 12h, Pour the mixture into 400mL of ice, add 3mL of hydrogen peroxide dropwise, and after stirring evenly, the solution becomes a yellow-brown suspension, which is centrifuged and washed 5 times with deionized water at a centrifugal rate of 10,000r / min. Disperse in 200mL deionized water, and ultrasonically vibrate for 3 hours to obtain a graphene oxide suspension.

[0040] Measure 10 mL of graphene oxide suspension, add 0.2 mL of single-head PEG to it, and set up a reflux device, protect it with argon, raise the temperature to 50 ° C, and keep stirring the solution at 500 r / min, add 2 mL of concentrated S...

Embodiment 2

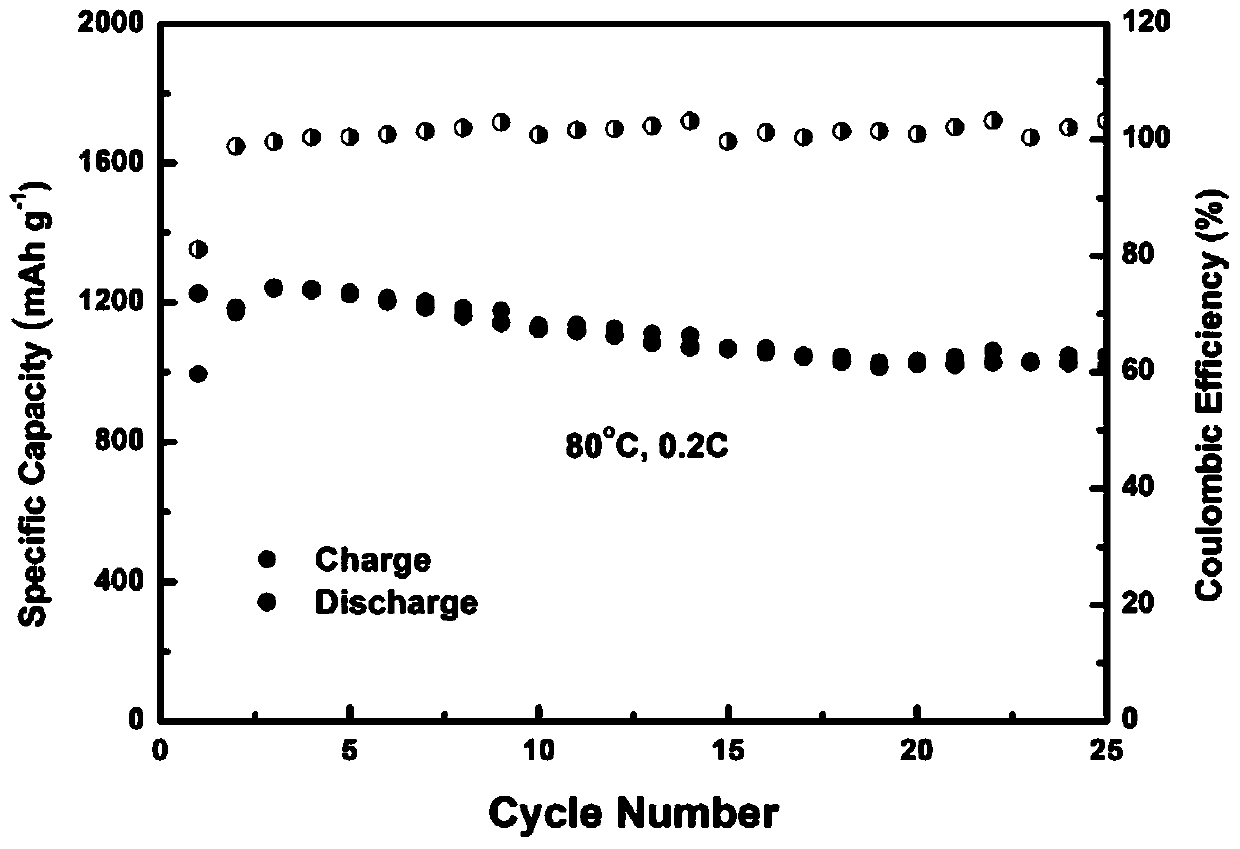

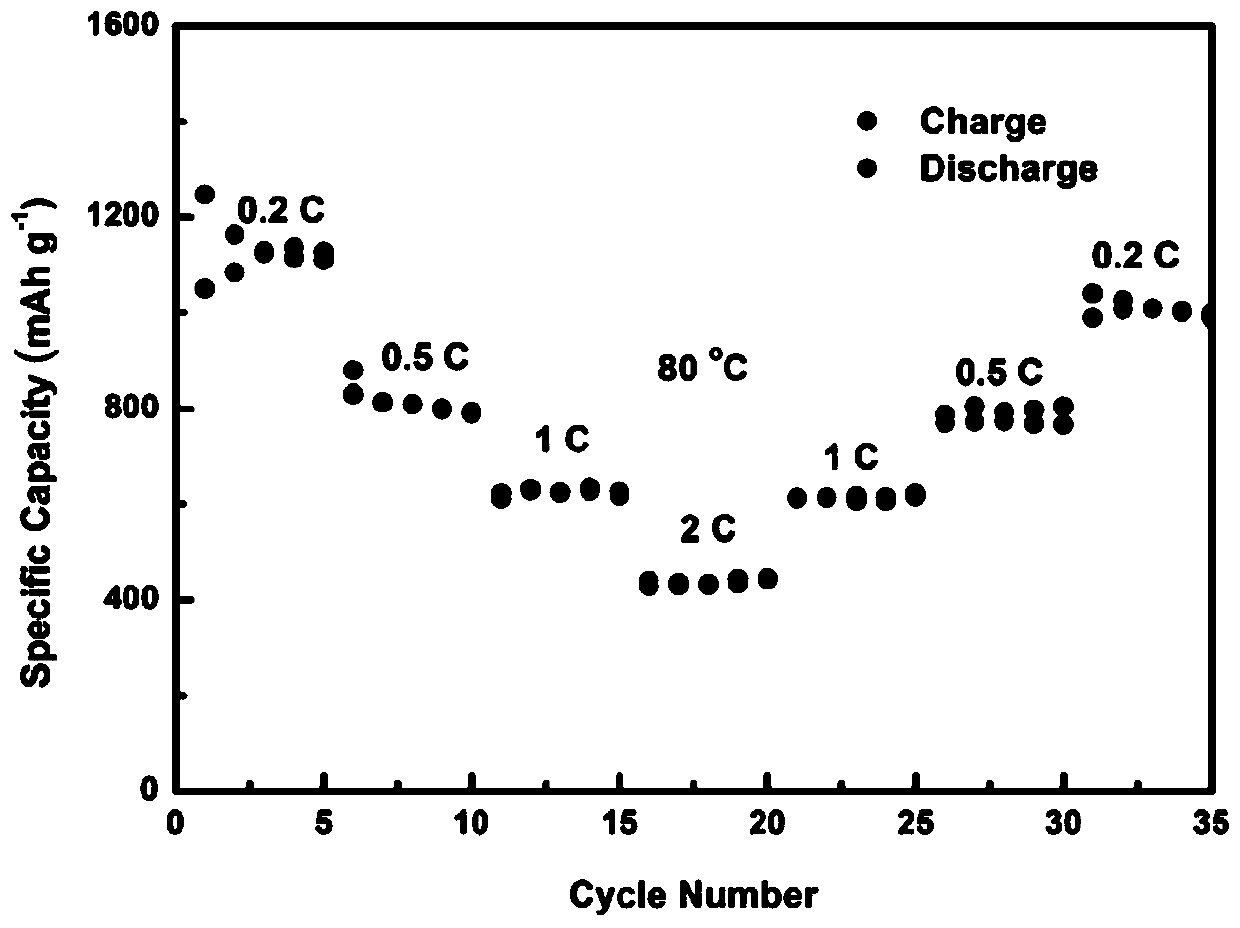

[0045] A bifunctional graphene oxide / sulfur composite material with the same material ratio as in Example 1 was prepared, assembled into an all-solid-state lithium-sulfur battery, and subjected to a 0.2C rate charge and discharge test at 80°C, and the first discharge specific capacity was 1234.2mAh / g , after 25 cycles, the discharge specific capacity is 1068.2mAh / g, and the efficiency is 98.9%. Under the condition of 80℃, the charge-discharge test with different rates was carried out. The specific capacity of the discharge at 0.2C in the first cycle was 1245.7mAh / g. After 5 cycles, the discharge specific capacity at 0.5 was 852.5mAh / g. After 10 cycles, the discharge specific capacity at 1C After 15 cycles, the discharge specific capacity at 2C is 422.8mAh / g. When the rate gradually returns to 0.2C, the discharge specific capacity is 985.6mAh / g after 35 cycles, and the efficiency is 98.3%.

Embodiment 3

[0047] Prepare the bifunctional graphene oxide / sulfur composite material and the positive electrode sheet with the same material ratio as in Example 1, and use the positive electrode sheet / lithium sulfide electrolyte / lithium sheet to prepare the positive electrode sheet of the lithium-sulfur battery Assembled into a liquid lithium-sulfur button battery, at 25°C and 0.1C, the specific discharge capacity of the first cycle is 1524mAh / g, and after 20 cycles, the discharge specific capacity is 1269mAh / g, and the efficiency is 98.3%. The 1C rate charge and discharge test was carried out at 25°C. The first discharge specific capacity was 1237.2mAh / g, and after 200 cycles, the discharge specific capacity was 875.2mAh / g, and the efficiency was 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com