Low-temperature fermented milk as well as raw material composition and preparation method thereof

A raw material composition and low-temperature fermentation technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of difficulty in meeting the health and nutrition demands of consumers in remote areas, short shelf life, etc., and achieve safety without toxic side effects , natural anti-corrosion effect, and the effect of reducing after-sales complaints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

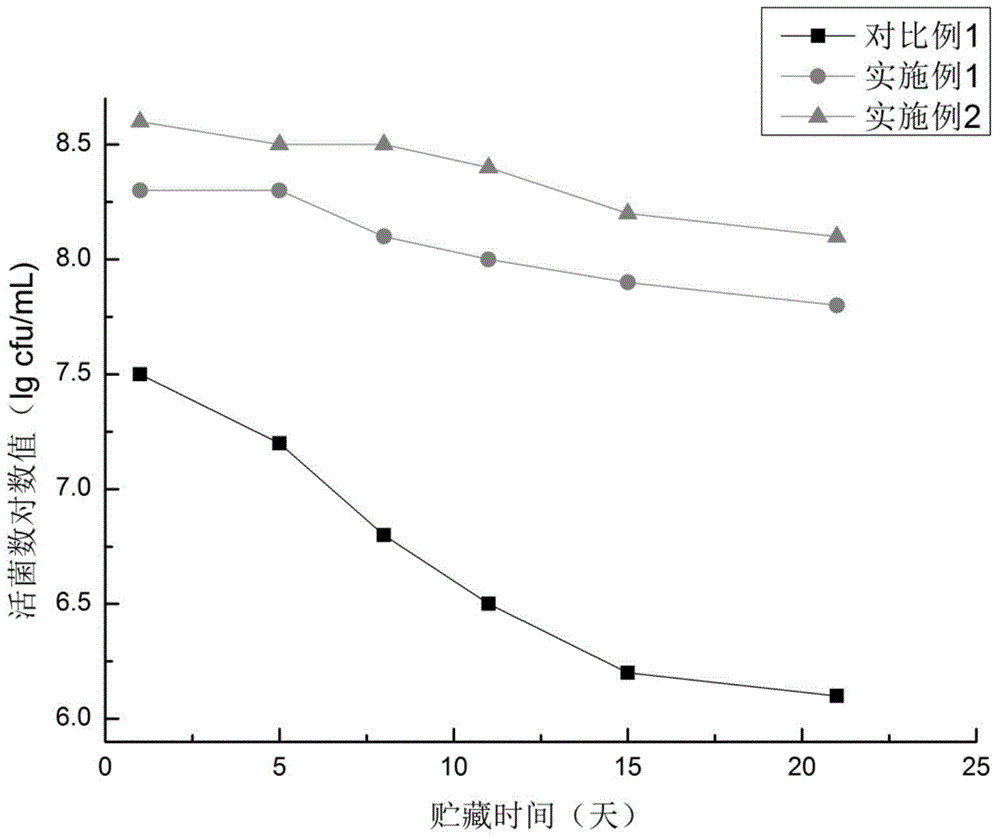

Embodiment 1

[0056] 1. Raw material formula:

[0057] Whole milk 92.122%, sucrose 7.0%, modified starch 0.6%, agar 0.07%, pectin 0.2%, fermentation bacteria (Lactobacillus bulgaricus and Streptococcus thermophilus) 0.006%, Lactobacillus casei LC2W 0.002%.

[0058] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0059] Two, produce the product of the present embodiment according to following process method:

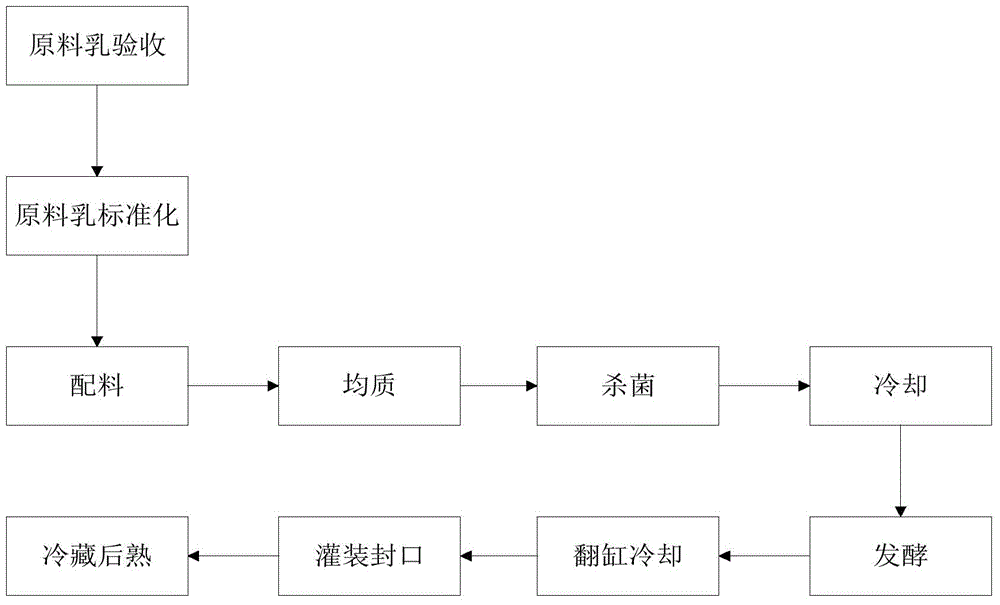

[0060] 1. Process flow:

[0061] Acceptance of raw milk→standardization of raw milk→ingredients→homogenization→sterilization→cooling→fermentation→turning tanks to cool→filling→refrigerating and then ripening

[0062] 2. Process description:

[0063] 2.1 Acceptance of raw milk: acceptance according to the standard requirements of GB19301.

[0064] 2.2 Raw milk standardization: The standardized indicators should meet the requirements of the factory's internal control indicators. Whole-fat raw milk is standardiz...

Embodiment 2

[0075] 1. Raw material formula:

[0076] Whole milk 92.12%, sucrose 7.0%, modified starch 0.6%, agar 0.07%, pectin 0.2%, fermentation bacteria (Lactobacillus bulgaricus and Streptococcus thermophilus) 0.006%, Lactobacillus casei LC2W 0.004%.

[0077] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0078] Two, produce the product of the present embodiment according to following process method:

[0079] 1. Process flow:

[0080] Acceptance of raw milk→standardization of raw milk→ingredients→homogenization→sterilization→cooling→fermentation→turning tanks to cool→filling→refrigerating and then ripening

[0081] 2. Process description:

[0082] 2.1 Acceptance of raw milk: acceptance according to the standard requirements of GB19301.

[0083] 2.2 Raw milk standardization: The standardized indicators should meet the requirements of the factory's internal control indicators. Whole-fat raw milk is standardize...

Embodiment 3

[0094] 1. Raw material formula:

[0095]Whole milk 91.841%, sucrose 7.0%, modified starch 0.6%, gelatin 0.3%, pectin 0.15%, mono- and diglyceride fatty acid ester 0.1%, fermentation bacteria (Lactococcus lactis subsp. , Lactococcus lactis subsp. diacetyl, Leuconostoc enterococci subsp. enterica, Bifidobacterium bifidum and Lactobacillus acidophilus) 0.005%, Lactobacillus casei LC2W 0.004%.

[0096] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0097] Two, produce the product of the present embodiment according to following process method:

[0098] 1. Process flow:

[0099] Acceptance of raw milk→standardization of raw milk→ingredients→homogenization→sterilization→cooling→fermentation→turning tanks to cool→filling→refrigerating and then ripening

[0100] 2. Process description:

[0101] 2.1 Acceptance of raw milk: acceptance according to the standard requirements of GB19301.

[0102] 2.2 Raw milk st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com