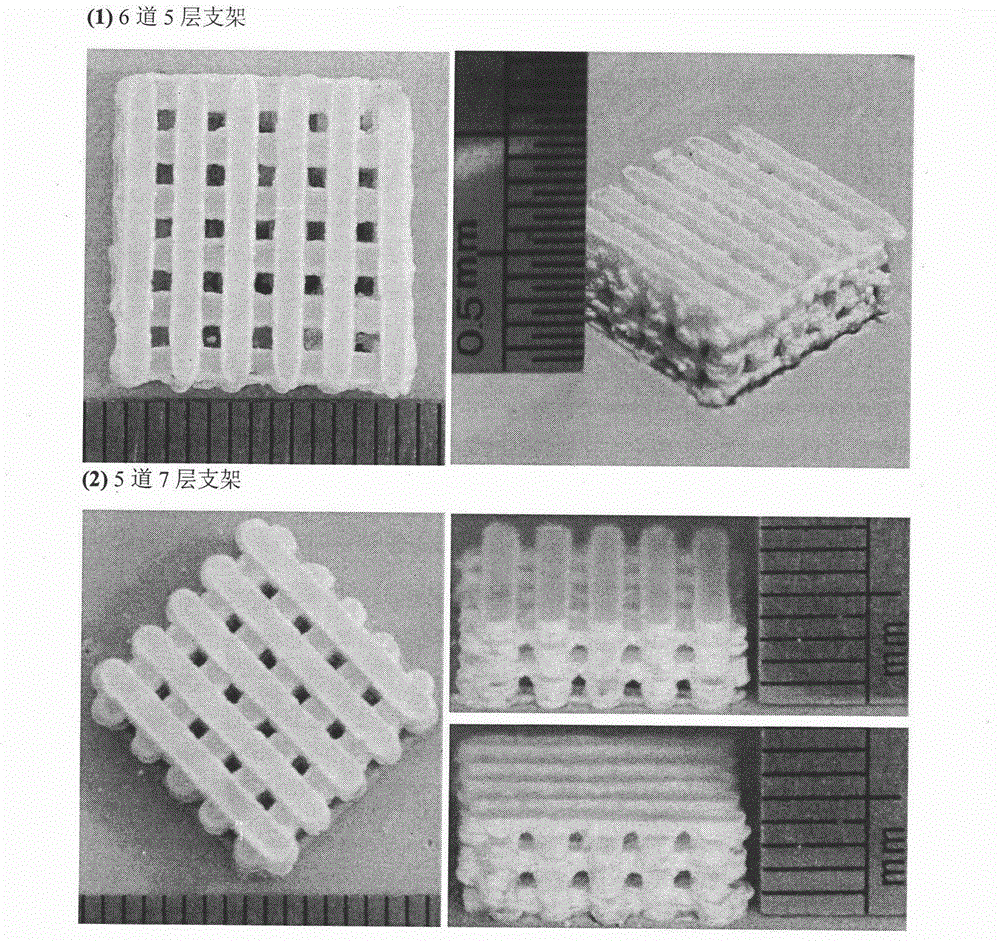

Construction method for composite ceramic bone scaffold surface micro-nano pores

A technology of composite ceramics and composite powders, applied in medical science, prostheses, etc., can solve the problems of difficult control of degradation rate, high brittleness, and insufficient bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with an embodiment, but the content of the present invention is not limited thereto.

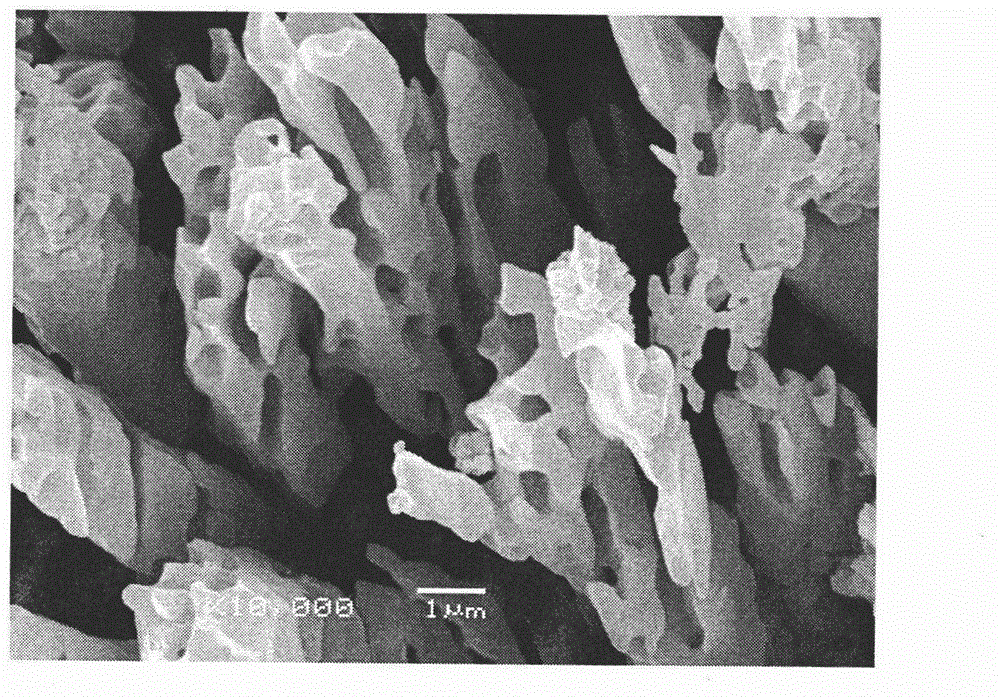

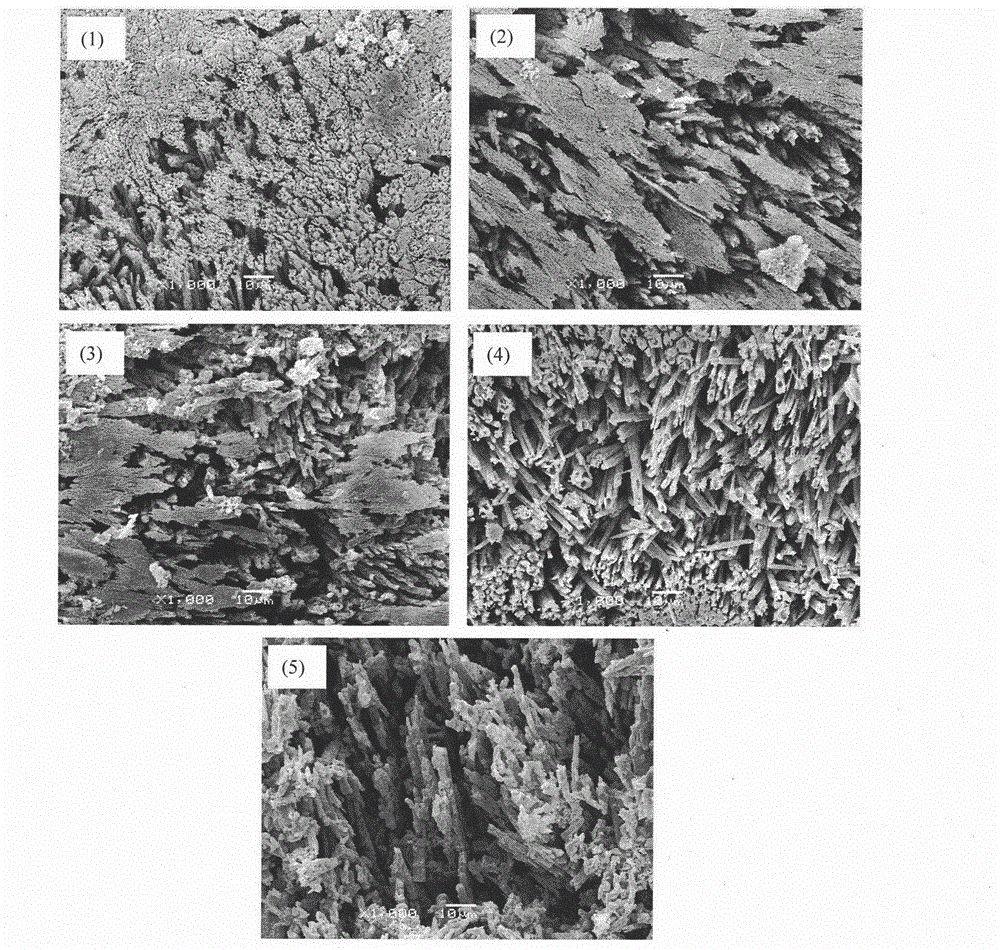

[0024] 1) Nano-HAP powder and β-TCP powder are used as raw materials. HAP powder is purchased from Nanjing Epurui Nano Material Co., Ltd. and prepared by sol-gel method. It is long needle-shaped, about 20nm wide, about 150nm long, and the average particle Diameter 40nm. β-TCP powder was provided by Kunshan Huaqiao Technology New Material Co., Ltd., China, prepared by precipitation method, and Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 As a raw material, it is prepared by calcining at 700-800°C and holding for 3-5 hours. The powder is white amorphous powder; the average particle size is 200nm, the melting point is 1670°C, and the bulk density is 0.75g / cm 3 , the Ca / P ratio is 1.50. The HAP / β-TCP composite powders with different ratios were obtained after grinding for 60 min by mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com