Preparation method for MoS2-BiPO4 composite photocatalyst

A technology of mos2-bipo4 and composite light, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve high photocatalytic activity, simple process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] (1) Add 1mmol MoO 3 Add 2.5mmol KSCN and 2.5mmol KSCN to 10ml deionized water, stir and mix evenly, transfer the raw materials to a 23ml reactor and react at 160°C for 32h, cool to room temperature, wash repeatedly with deionized water, and vacuum dry at 60°C for 12h;

[0011] (2) Take 3mg of graphene-like MoS prepared in step (1) 2 Dissolve in 20ml ethylene glycol solution and ultrasonically disperse for 40min, ultrasonic power 90W, to obtain uniform MoS 2 Dispersions;

[0012] (3) Take 1mmol Bi(NO 3 ) 3 Join the MoS 2 Magnetically stir the dispersion until it is completely dissolved, then add 1mmol NaH 2 PO 4 , mixed evenly, transferred to a hydrothermal kettle and heated in a microwave at 180°C for 60 minutes. After the reaction was completed, MoS was obtained by cooling, washing and drying. 2 -BiPO 4 composite photocatalyst.

Embodiment 2

[0014] (1) Add 1mmol MoO 3 Add 2.5mmol KSCN and 2.5mmol KSCN to 10ml deionized water successively with magnetic stirring, mix evenly, transfer the raw materials to a 23ml reaction kettle, react at 200°C for 12h, after cooling to room temperature, wash repeatedly with deionized water, and vacuum dry at 60°C for 12h;

[0015] (2) Take 6mg of graphene-like MoS prepared in step (1) 2 Dissolve in 40ml ethylene glycol solution and ultrasonically disperse for 20min with ultrasonic power of 90W to obtain uniform MoS 2 Dispersions;

[0016] (3) Take 1mmol Bi(NO 3 ) 3 Join the MoS 2 Magnetically stir the dispersion until it is completely dissolved, then add 1mmol NaH 2 PO 4 , mixed evenly, transferred to a hydrothermal kettle and heated in a microwave at 160°C for 120min. After the reaction was completed, MoS was obtained by cooling, washing and drying. 2 -BiPO 4 composite photocatalyst.

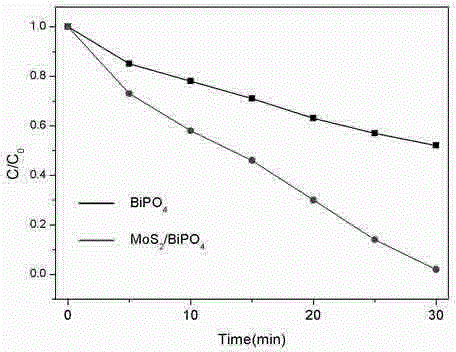

[0017] figure 1 Under the irradiation of a 125W high-pressure mercury lamp, the MoS prep...

Embodiment 3

[0019] (1) Add 1mmol MoO 3 Add 2.5mmol KSCN and 2.5mmol KSCN to 10ml deionized water, stir magnetically, mix evenly, transfer the raw materials to a 23ml reactor and react at 180°C for 24h, cool to room temperature, wash repeatedly with deionized water, and vacuum dry at 60°C for 12h;

[0020] (2) Take 9mg of graphene-like MoS prepared in step (1) 2 Dissolve in 10ml ethylene glycol solution and ultrasonically disperse for 60min, ultrasonic power 90W, to obtain uniform MoS 2 Dispersions;

[0021] (3) Take 1mmol Bi(NO 3 ) 3 Join the MoS 2 Magnetically stir the dispersion until it is completely dissolved, then add 1mmol NaH 2 PO 4 , mixed evenly, transferred to a hydrothermal kettle and heated in a microwave at 200°C for 30 minutes. After the reaction was completed, MoS was obtained by cooling, washing and drying. 2 -BiPO 4 composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com