A kind of method of reducing graphene oxide

A technology of graphene and graphite, applied in the field of graphene, can solve the problems of high pollution, long cycle, high toxicity, etc., and achieve the effect of simple process, good reduction effect and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

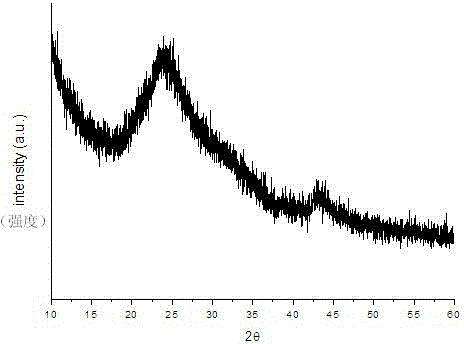

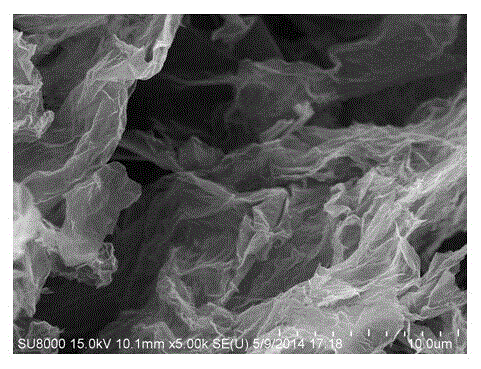

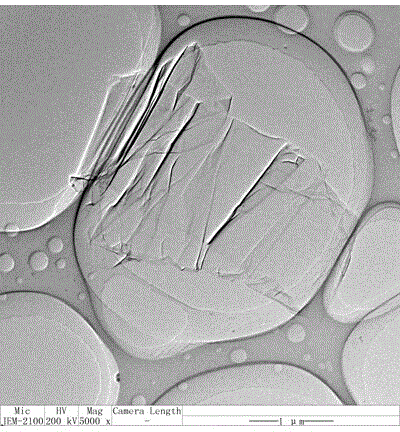

Image

Examples

Embodiment 1

[0029] The reduction method of the graphene oxide of the present embodiment comprises the following steps:

[0030] 1) Preparation of aqueous dispersion of graphene oxide (preparation of graphene oxide by self-developed phosphoric acid sealing method): first, mix 200g of natural graphite and 5L of mixed acid consisting of 4.5L of concentrated sulfuric acid and 0.5L of concentrated phosphoric acid in the reaction kettle , and stir evenly with an electronically controlled magnetic stirrer, and slowly add 500g of potassium permanganate under the condition of lower than 20°C; after that, seal the reaction kettle and raise the temperature to 80°C for 2 hours, take the product out from the lower end of the reaction kettle, add Dilute it with ionic water into a 40L solution, add 0.6L hydrogen peroxide to obtain a bright yellow graphite oxide solution; then, alternately centrifuge and wash with acid (hydrochloric acid) and water until the solution pH=5~6 to remove impurity ions; finall...

Embodiment 2

[0033] The reduction method of the graphene oxide of the present embodiment comprises the following steps:

[0034] 1) Preparation of aqueous dispersion of graphene oxide (preparation of graphene oxide by self-developed phosphoric acid sealing method): first, mix 200g of natural graphite and 5L of mixed acid consisting of 4.5L of concentrated sulfuric acid and 0.5L of concentrated phosphoric acid in the reaction kettle Stir evenly with an electronically controlled magnetic stirrer, and slowly add 500g of potassium permanganate at a temperature lower than 20°C; after that, seal the reaction kettle and raise the temperature to 75°C for 4 hours, take the product out of the lower end of the reaction kettle, and dilute it to 40L Solution, add 0.6L hydrogen peroxide to get a bright yellow graphite oxide solution; then, use acid (sulfuric acid) and water to alternately centrifuge and wash until the solution pH=5~6 to remove impurity ions; finally, ultrasonically disperse graphite oxid...

Embodiment 3

[0037] The reduction method of the graphene oxide of the present embodiment comprises the following steps:

[0038] 1) Preparation of aqueous dispersion of graphene oxide (preparation of graphene oxide by self-developed phosphoric acid sealing method): first, mix 200g of natural graphite and 5L of mixed acid consisting of 4.5L of concentrated sulfuric acid and 0.5L of concentrated phosphoric acid in the reaction kettle Stir evenly with an electronically controlled magnetic stirrer, and slowly add 500g of potassium permanganate at a temperature lower than 20°C; after that, seal the reaction kettle and raise the temperature to 85°C for 1 hour, take the product out of the lower end of the reaction kettle, and dilute it to 40L Solution, add 0.6L hydrogen peroxide to obtain a bright yellow graphite oxide solution; then, alternately centrifuge and wash with acid and water until the solution pH=5~6 to remove impurity ions; finally, ultrasonically disperse graphite oxide to prepare a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com