Atom transfer radical polymerization method based on liquid/liquid two-phase catalysis system

A catalytic system and atom transfer technology, applied in the field of catalytic polymerization, can solve the problems of time-consuming, labor-intensive, high-cost, and large-scale application limitations, and achieve the effects of reducing the residual amount of metal salts, easy operation, and strong designability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

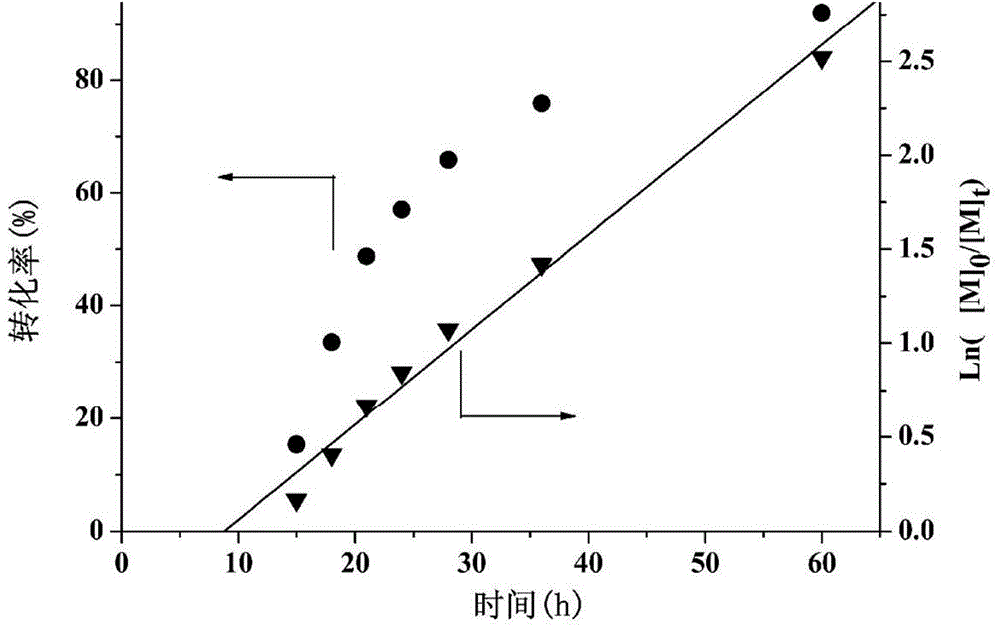

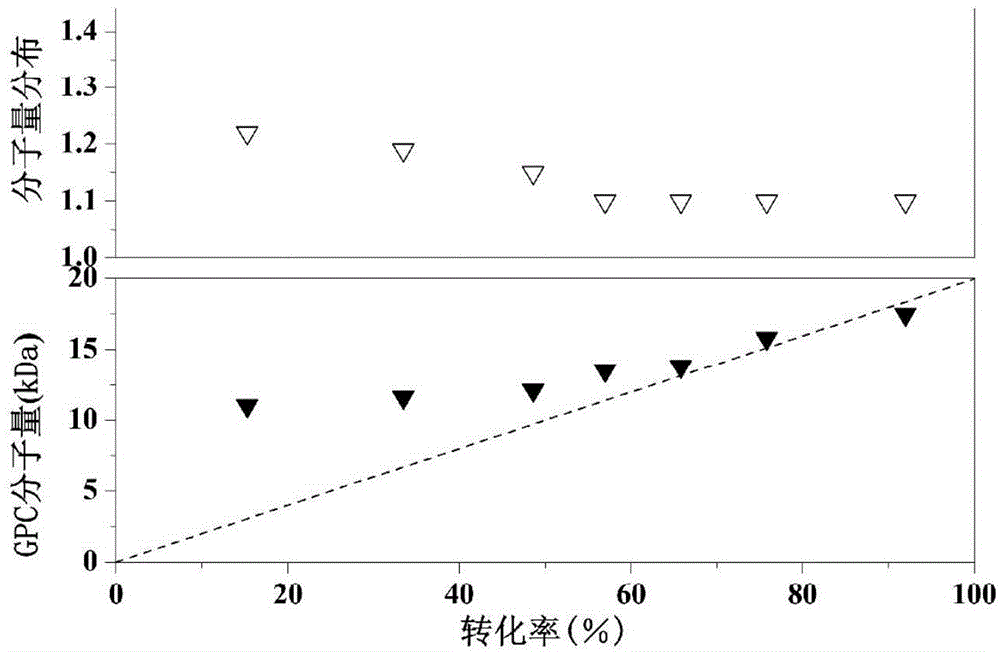

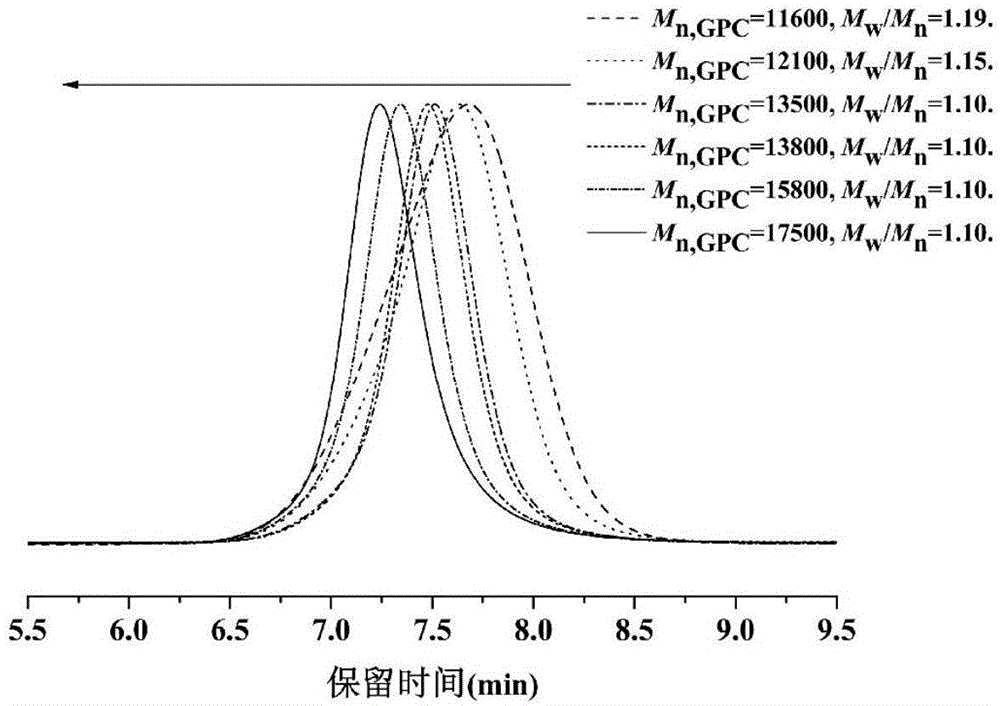

[0043] Example 1: Polymerization of MMA based on a liquid / liquid two-phase catalytic system.

[0044] according to n 单体 :n 引发剂 :n 催化剂 :n 配体 :n 还原剂 =200:1:2:2:0.2 initial molar ratio, monomer MMA (1.0 mL, 9.44 mmol), initiator EBrPA (8.25 μL, 0.0472 mmol), reducing agent AIBN (1.55 mg, 9.44×10 -3 mmol) was added to 2 mL of toluene, the catalyst CuBr 2 (21.2 mg, 0.0944 mmol), the ligand TPMA (27.4 mg, 0.0944 mmol) was added to 2 mL of purified water, and the two phases of water and organic solvent were mixed in a clean 10 mL ampoule, which was directly sealed without deoxygenation operation. Tube. Then the ampoule was transferred to an oil bath at a set temperature (75°C) and rotating speed (1800 rpm) for polymerization, after a given time (24 h), it was taken out and placed in ice water to cool and separate, and then Dilute the upper organic phase with THF, pour it into a large amount of methanol for precipitation, filter it with suction, and dry it in vacuum to obtain ...

Embodiment 2

[0045] Example 2: Polymerization of MMA based on a liquid / liquid two-phase catalytic system.

[0046] according to n 单体 :n 引发剂 :n 催化剂 :n 配体 :n 还原剂 =100:1:1:1:0.1 initial molar ratio, the monomer MMA (0.5 mL, 4.72 mmol), the initiator EBrPA (16.5 μL, 0.0944 mmol), the reducing agent AIBN (1.55 mg, 9.44×10 -3 mmol) into 1 mL of toluene, the catalyst CuBr 2 (21.2 mg, 0.0944 mmol), the ligand TPMA (27.4 mg, 0.0944 mmol) was added to 3 mL of purified water, and the two phases of water and organic solvent were mixed in a clean 10 mL ampoule. Tube. Then the ampoule was transferred to an oil bath at a set temperature (90°C) and rotating speed (1600 rpm) for polymerization, after a given time (30 h), it was taken out and placed in ice water to cool and separate, and then Dilute the upper organic phase with THF, pour it into a large amount of methanol for precipitation, filter it with suction, and dry it in vacuum to obtain the desired polymer.

Embodiment 3

[0047] Example 3: Effects of Different Initiator Types on Liquid / Liquid Two-phase Catalytic ATRP.

[0048] For ATRP polymerization, especially the ATRP polymerization of oil-soluble monomers in the water phase, the ATRP initiator plays a very critical role, which can affect the initiation efficiency, polymerization rate and terminal functionalization degree of the polymer in the entire polymerization stage, etc. . For this purpose, we follow the method recorded in Example 1, intending to use different initiators such as ethyl 2-bromoisobutyrate (EBiB), ethyl α-bromophenylacetate (EBrPA), 2-bromopropionitrile (BPN), MPEG550-Br, etc. prepared a series of polymers in parallel to investigate the effect of several conventional ATRP initiators on the polymerization of MMA under the liquid / liquid two-phase catalytic system. The results are shown in Table 1 below.

[0049]

[0050] Aggregation condition: except [MMA] 0 :[MPEG550-Br] 0 =100:1 other than [MMA] 0 :[Initiator] 0 :...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com