A kind of preparation method and product of ultra-thin high-strength hydrogel film

A high-strength, hydrogel technology, which is applied in the field of hydrogel film preparation, can solve the problems of complex preparation process and unrecyclable hydrogel film, and achieve simple preparation method, low cost and simple film forming method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

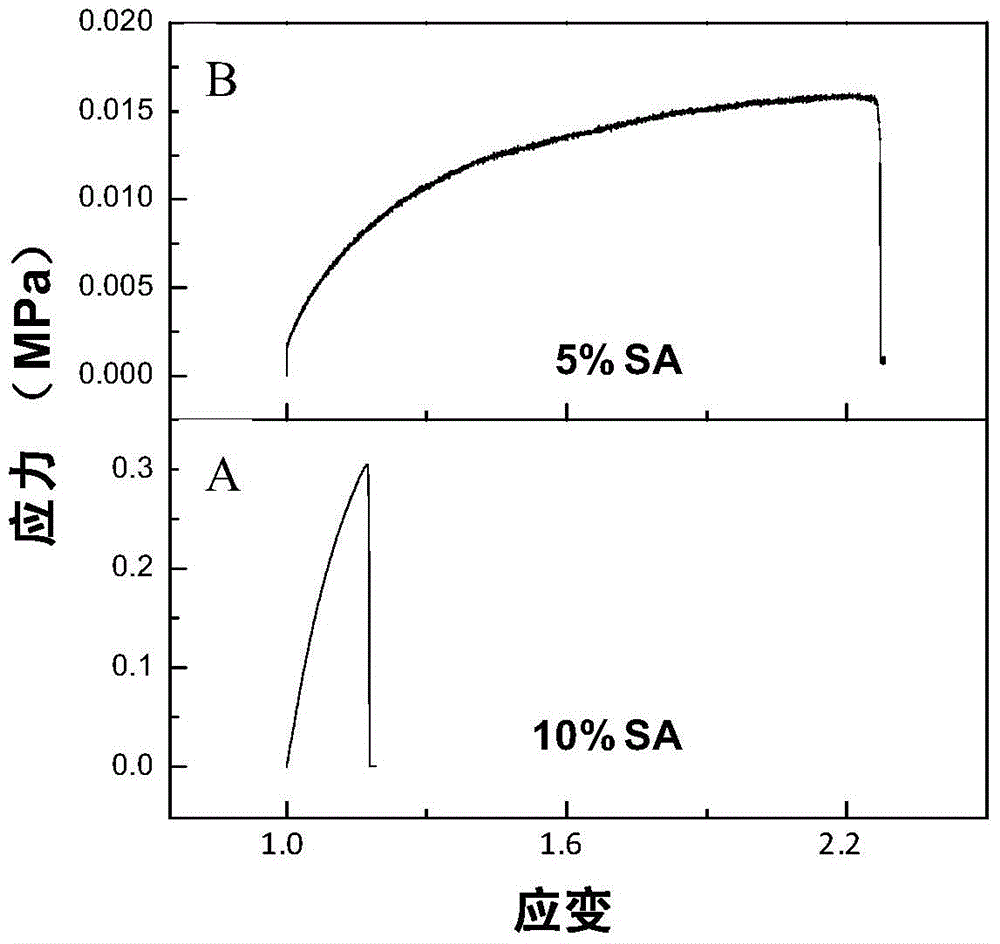

[0054] Take a random copolymer hydrogel film containing 10% stearyl acrylate as an example:

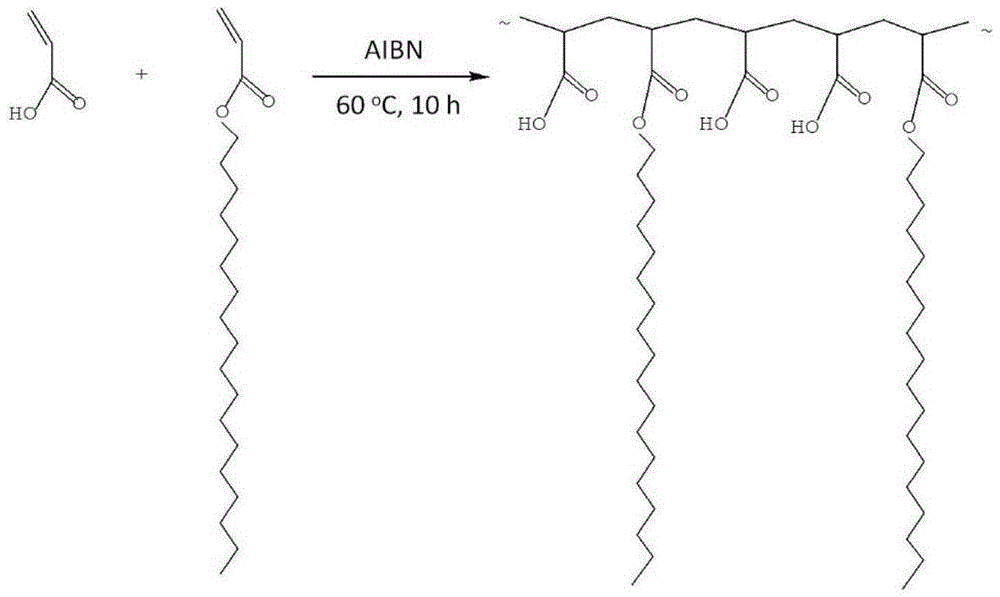

[0055] (1) Prepare an ethanol solution containing 2.7 mol / L acrylic acid monomer, 0.3 mol / L stearyl acrylate (SA) and 0.03 mol / L azobisisobutyronitrile (the total monomer concentration is 3 mol / L). Azobisisobutyronitrile (AIBN) was used as a thermal initiator, and the polymerization reaction was carried out in the absence of oxygen at 60°C for 10 hours to obtain a transparent and viscous ethanol solution of acrylic acid-octadecyl acrylate random copolymer.

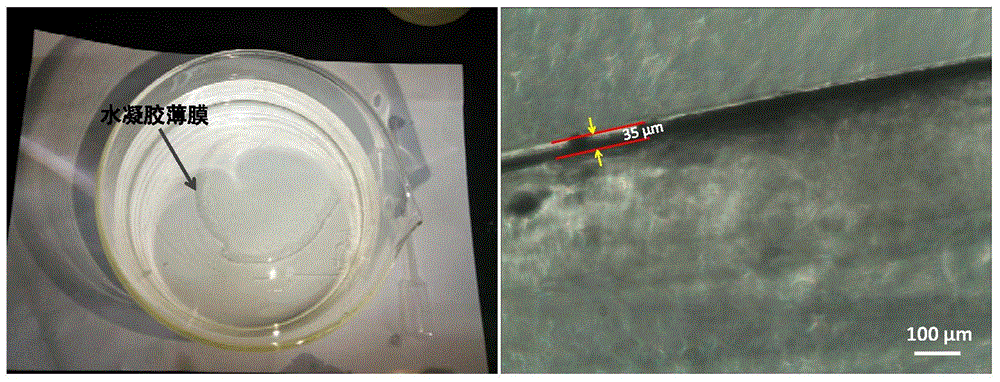

[0056] (2) Configure ethanol / water mixed solvent containing 5% volume content in a watch glass as film-forming liquid, draw acrylic acid-stearyl acrylate random copolymer ethanol solution and drop 3 drops into ethanol / water mixed solvent with a dropper middle. The random copolymer solution spread rapidly on the surface of ethanol / water mixed solvent, and formed a physical hydrogel film after solvent exchange.

[0057] (3) The hy...

Embodiment 2

[0062] Take a random copolymer hydrogel film containing 5% stearyl acrylate as an example:

[0063] (1) Prepare an ethanol solution containing 2.85 mol / L acrylic acid monomer, 0.15 mol / L octadecyl acrylate and 0.03 mol / L azobisisobutyronitrile (the total monomer concentration is 3 mol / L). AIBN was used as a thermal initiator, and the polymerization reaction was carried out in the absence of oxygen at 60°C for 10 hours to obtain a transparent and viscous ethanol solution of acrylic acid-stearyl acrylate random copolymer.

[0064] (2) Configure ethanol / water mixed solvent containing 2% volume content in a watch glass as a film-forming liquid, use a dropper to draw acrylic acid-stearyl acrylate random copolymer ethanol solution and drop 3 drops into the ethanol / water mixed solvent middle. The random copolymer solution spread rapidly on the surface of ethanol / water mixed solvent, and formed a physical hydrogel film after solvent exchange.

[0065] The hydrogel film prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com