Formula and preparation process of phosphate starch-vegetable gum copolymer film

A film preparation and phosphate ester technology, applied in the field of plastic film production, can solve the problems of affecting stability, poor water resistance, refractory, etc., and achieve the effect of low production cost, low price, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

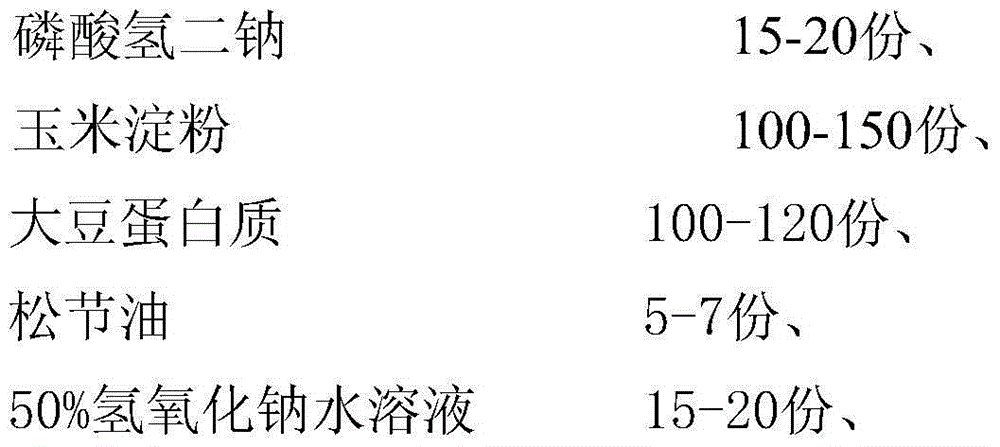

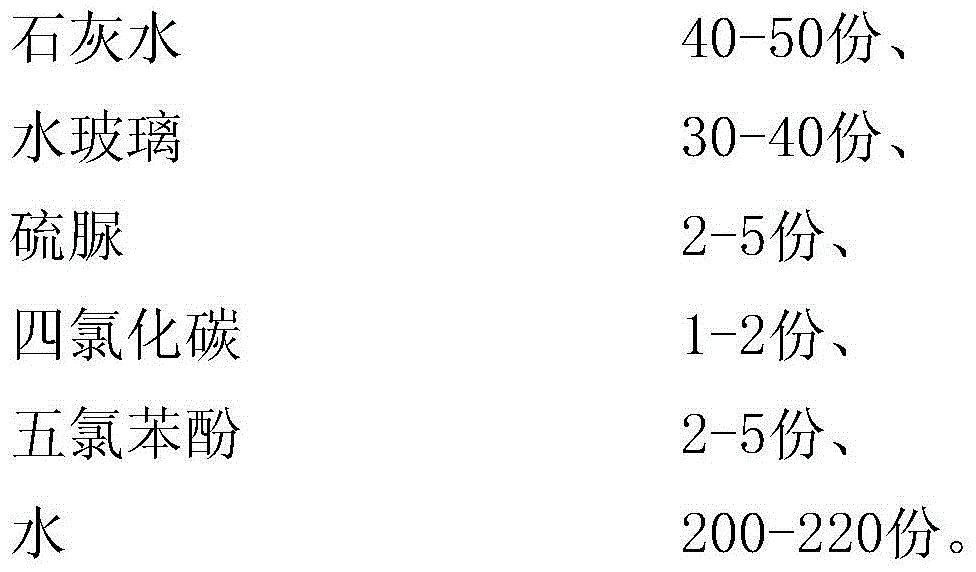

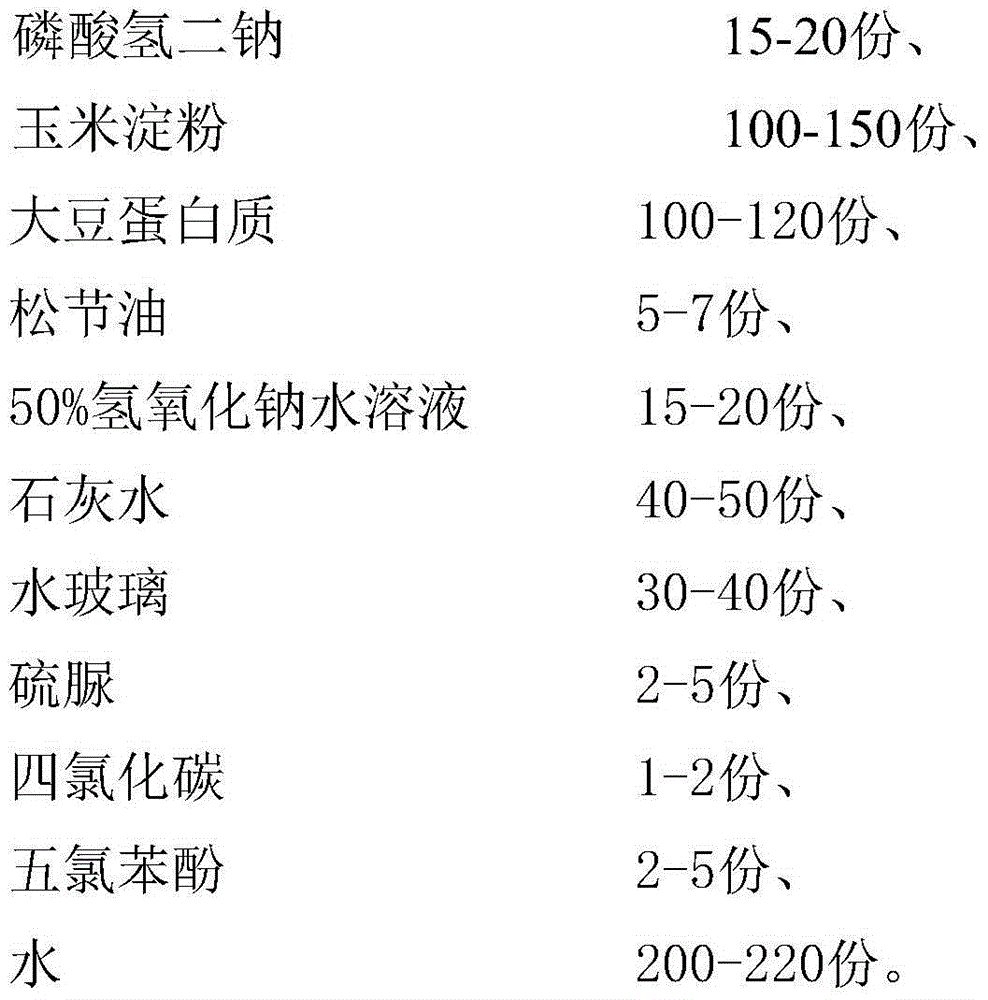

[0017] Specific embodiment: phosphate ester starch-vegetable glue copolymer film formula, its composition mainly comprises: 15 parts of disodium hydrogen phosphate, 100 parts of cornstarch, 100 parts of soybean protein, 5 parts of turpentine, 15 parts of 50% sodium hydroxide aqueous solution, lime 40 parts of water, 30 parts of water glass, 2 parts of thiourea, 1 part of carbon tetrachloride, 2 parts of pentachlorophenol, and 200 parts of water.

[0018] Phosphate starch-vegetable glue copolymer film preparation process specifically comprises the following steps:

[0019] Step 1: Put water and disodium hydrogen phosphate into the mixing tank according to the proportion, heat up to 60°C under constant stirring, so that the disodium hydrogen phosphate solution is completely dissolved, and fully mix the corn starch and disodium hydrogen phosphate solution according to the proportion Put it into the reactor, stir the material in the reactor and raise the temperature to 70-80°C. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com