Lithium battery diaphragm compounded from aqueous polymer and inorganic nanoparticles and preparation method thereof

A technology of inorganic nanoparticles and lithium battery separators, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problem that the thermal safety ability is difficult to meet the requirements, achieve good absorption and retention of electrolyte, and improve Effect of wettability and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

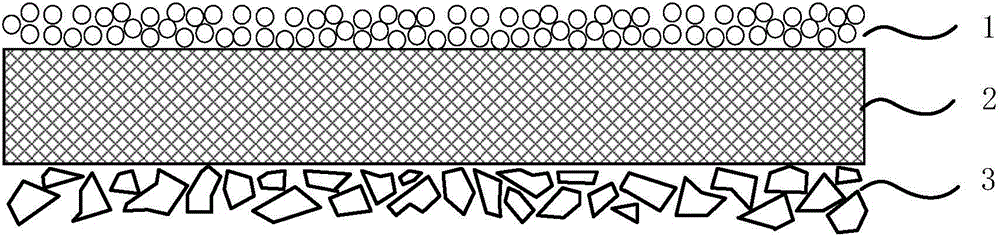

[0029] The preparation method is divided into two major steps, first polymer coating, and then ceramic coating on the other side, the specific steps are as follows:

[0030] a) Preparation and coating of aqueous polymer slurry

[0031] a1: Using deionized water as solvent, dissolve water-soluble adhesives, surfactants, dispersants, thickeners, etc. under high-speed stirring at room temperature to form a solution; then add polymer powder particles and stir evenly at high speed. A water-based slurry; the slurry contains 0.1%-2% water-soluble polymer thickener, 0.01%-2% water-based dispersant, 0.01%-1% surfactant, 0.1%-5% water-based Adhesive, 5% to 25% polymer powder particles, 67% to 83% deionized water, all of the above are mass fractions;

[0032] a2: Using micro-gravure roll coating, apply the aqueous slurry prepared in step a1 to one surface of the support layer diaphragm at a coating rate of 5-100m / min;

[0033] a3: Dry the coating film obtained in step a2 in an oven at 30-100°C;...

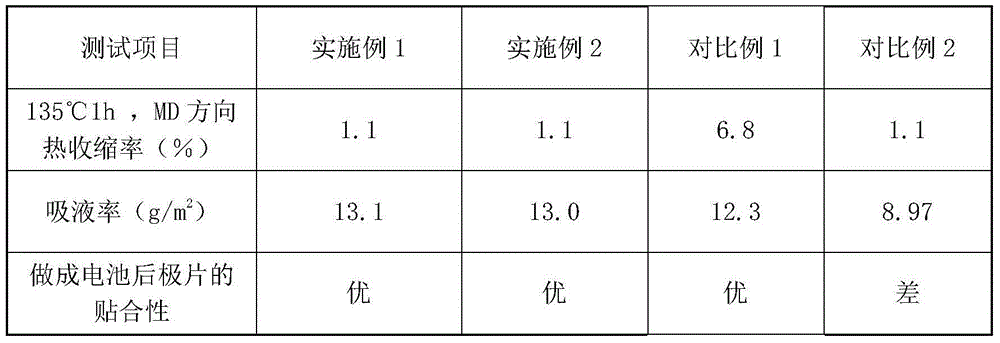

Embodiment 1

[0043] 1) Preparation of aqueous PVDF slurry

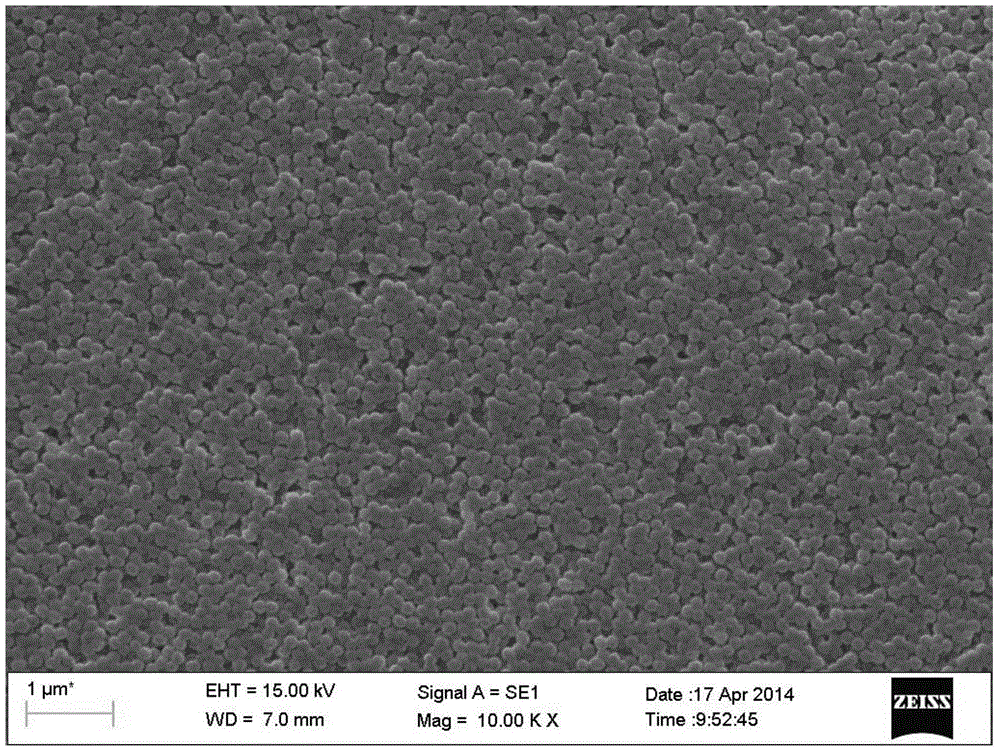

[0044] The polymer coating layer is coated by an aqueous slurry, and the weight ratio of the slurry is PVDF-HFP: deionized water = 100:500. First, add acrylic adhesive and tackifier CMC into deionized water, stir at 300r / min for 20 minutes at room temperature until completely dissolved. The weight ratio of acrylic adhesive and CMC is adhesive: PVDF- HFP=5:100, CMC:PVDF-HFP=1:100. Then add fluorocarbon surfactant, dispersant polyvinylpyrrolidone (PVP) and PVDF-HFP powder to the above solution in sequence, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min at high speed, the slurry configuration is completed. Among them, fluorocarbon surfactant: PVDF-HFP=0.1:100, PVP:PVDF-HFP=0.3:100. The weight average molecular weight of PVDF-HFP is about 140,000, and the particle size is 100-300nm.

[0045] 2) Preparation of ceramic slurry

[0046] Weight ratio in slurry Al 2 O 3 : Deionized water = 100:150. First, add P...

Embodiment 2

[0051] 1) Preparation of aqueous PVDF slurry

[0052] The polymer coating layer is coated by an aqueous slurry, and the weight ratio of the aqueous slurry is PVDF-HFP: deionized water = 100:500. First, add the adhesive PVA and the thickener CMC into deionized water, stir at 300r / min for 20 minutes at room temperature until completely dissolved, the weight ratio of PVA and CMC is PVA: PVDF-HFP = 5: 100, CMC : PVDF-HFP=1:100. Then add fluorocarbon surfactant, dispersant polyoxyethylene dioleate and PVDF-HFP powder to the above solution in sequence, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min, the slurry configuration is complete . Among them, fluorocarbon surfactant: PVDF-HFP=0.1:100, and polyoxyethylene dioleate:PVDF-HFP=0.3:100. The weight average molecular weight of PVDF-HFP is about 140,000, and the particle size is 100-300nm.

[0053] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com