Method and apparatus for detecting membrane damage based on electrochemistry and magnetic bead technology

A detection device and detection method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of insensitive detection, inability to online detection, small application range, etc., to achieve high detection sensitivity and improve production. Efficiency, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

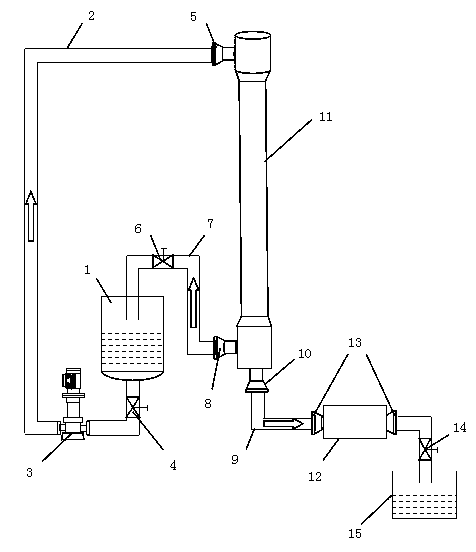

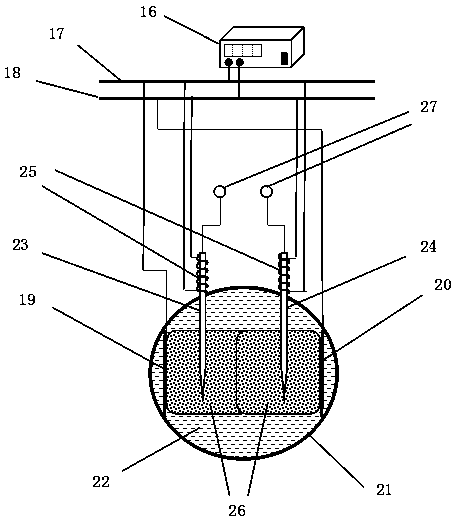

[0020] see figure 1 , a membrane damage detection device based on electrochemical and magnetic bead technology of the present invention mainly includes: raw liquid tank 1, raw liquid feed pipeline 2, booster pump 3, concentrated liquid outlet pipe 7, clear liquid outlet pipe 9, membrane module 11 , magnetic bead detection device 12, clear liquid tank 15, etc. The feed liquid to be treated is packed in the stock solution tank 1, the center of the bottom of the stock solution tank 1 is connected to one end of the stock solution feed pipe 2, and the other end of the stock solution feed pipe 2 is connected to the upper end of the membrane module 11 through the stock solution feed pipe flange 5. The first valve 4 is set on the stock solution feed pipeline 2 near the bottom of the stock solution tank 1, the first valve 4 is used to control the circulation of the stock solution, and is installed on the stock solution feed pipe 2 between the first valve 4 and the membrane module 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com