Bio-compostable polyester material composition and preparation method thereof

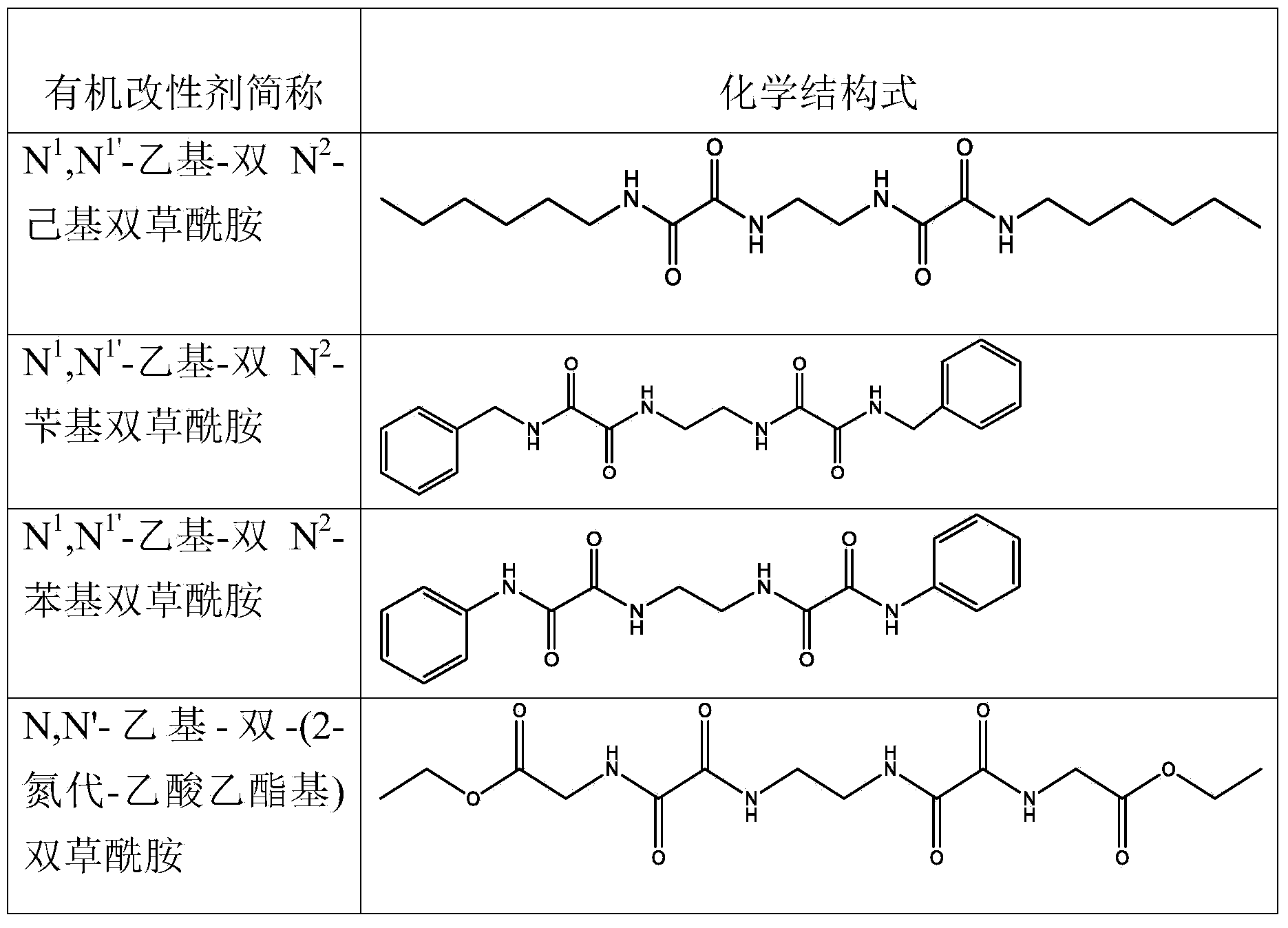

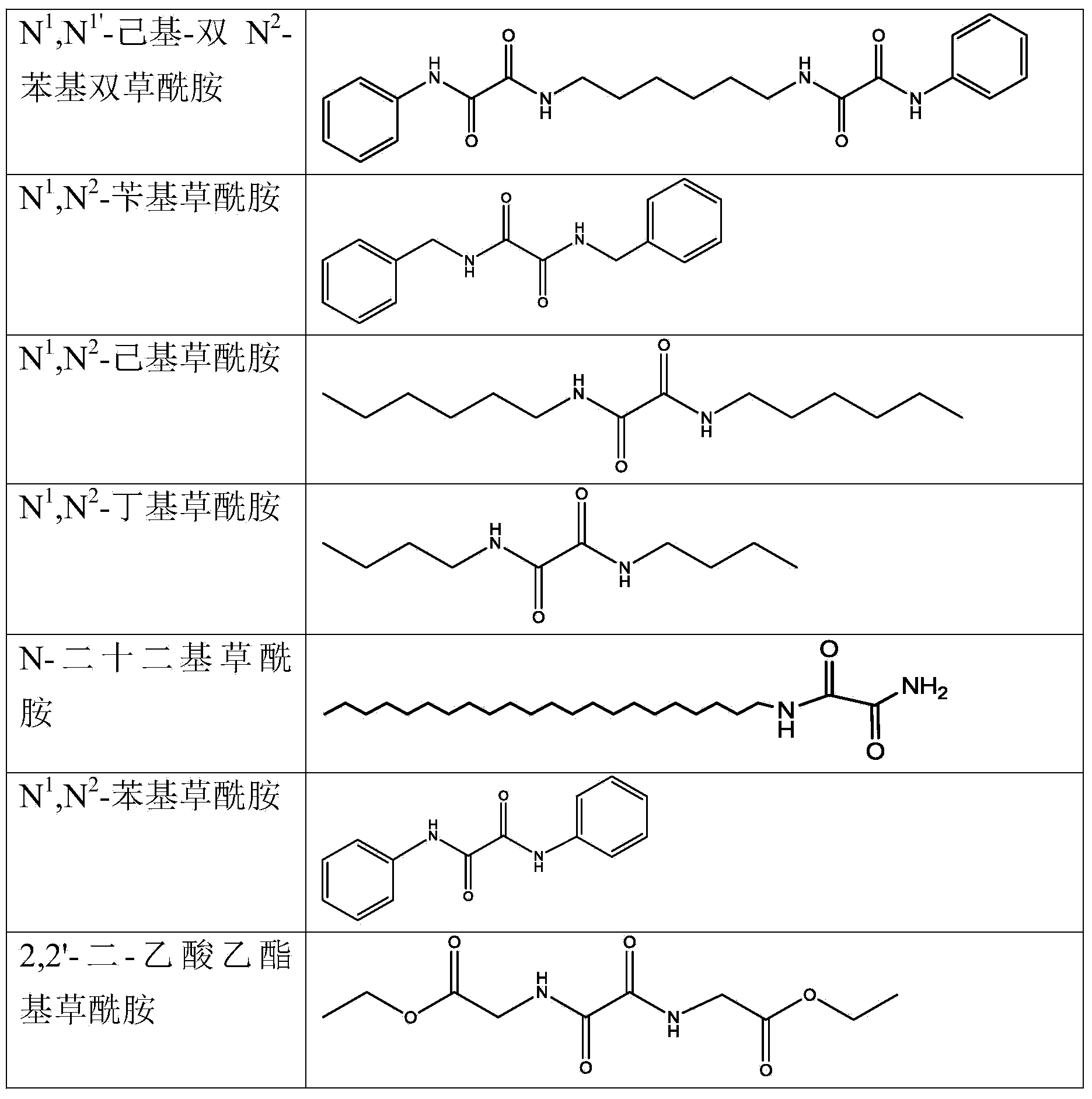

A technology of polyester materials and compositions, which is applied in the field of organic modifiers, compositions and their preparation, and can solve problems such as easy agglomeration, poor compatibility, and affecting the mechanical properties of products and the appearance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

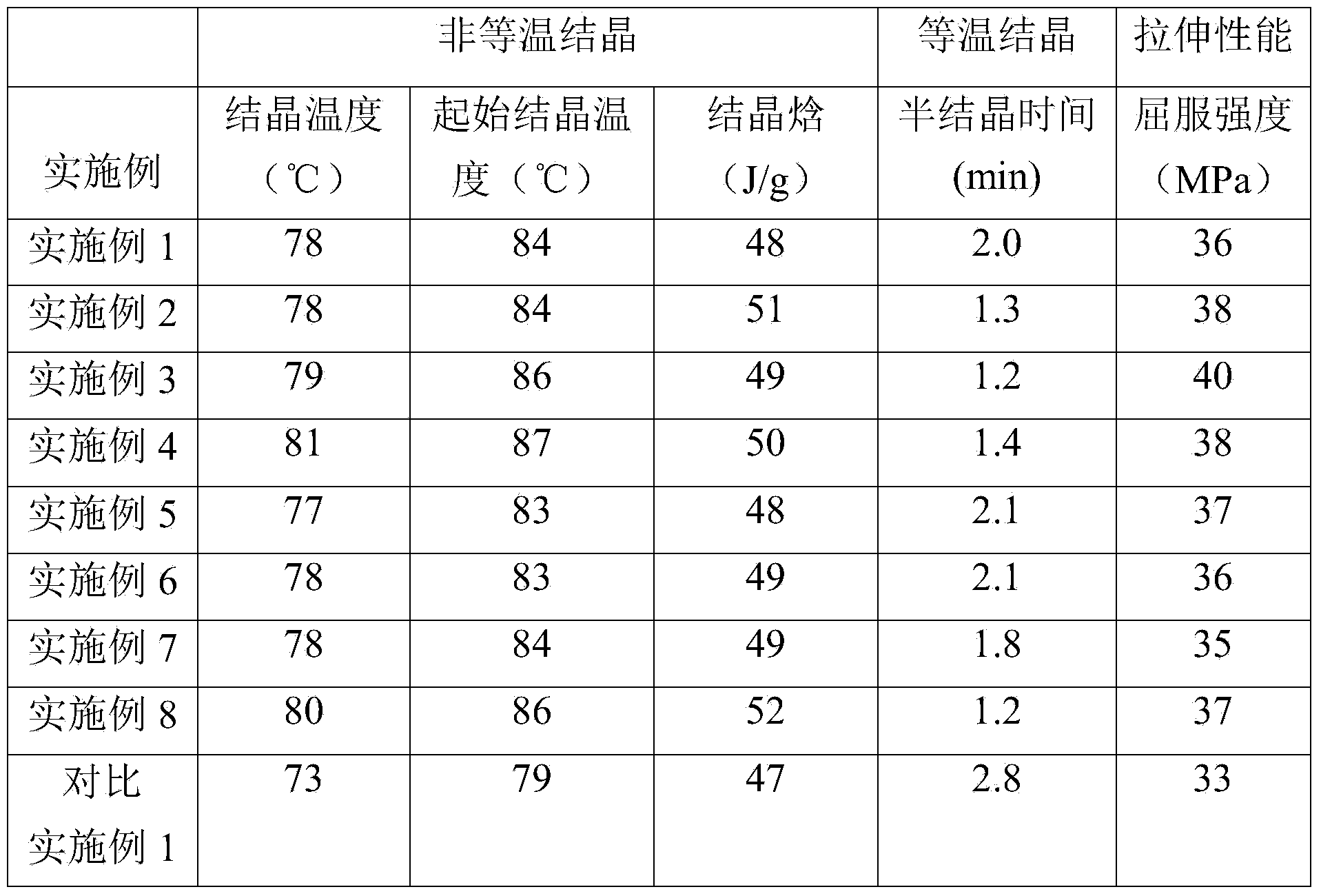

Examples

Embodiment 1

[0072] First dry polybutylene succinate 50g, N 1 ,N 1' -Ethyl-bis-N 2 0.4g of -phenyl bisoxamide, 0.3g of epoxidized soybean oil, 0.2g of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane and mix well at room temperature The premix was obtained, and then the above premix was melt-blended with an internal mixer at 130° C. for 5 minutes, and the rotor speed of the internal mixer was 50 rpm to obtain a polybutylene succinate material composition.

Embodiment 2

[0074] First dry polybutylene succinate 50g, N 1 ,N 1' -Ethyl-bis-N 2 - 0.5 g of phenyl bisoxamide was uniformly mixed at room temperature to obtain a premix, and then the above premix was melt blended at 130° C. for 5 minutes with an internal mixer, and the rotor speed of the internal mixer was 50 rpm to obtain a polybutylene Butylene glycol diacid material composition.

Embodiment 3

[0076] First dry polybutylene succinate 50g, N 1 ,N 1' -Ethyl-bis-N 2 -Phenyl bisoxamide 0.75g, Mix 0.2g of ADR43000, 0.2g of stearyl propionate, and 1g of talc powder at room temperature to obtain a premix, and then use an internal mixer to melt and blend the above premix for 5 minutes at 130°C. At 50 rpm, a polybutylene succinate material composition was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com