A kind of medical polyurethane pancreatic-intestinal stapler material and preparation method thereof

A technology of pancreaticojejunostomy and polyurethane, which is applied in the field of cast polyurethane polymer materials and its preparation, can solve the problems of poor anastomosis and growth of pancreas and intestines, achieve the effects of improving the surface and physical and chemical properties, improving mechanical properties, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

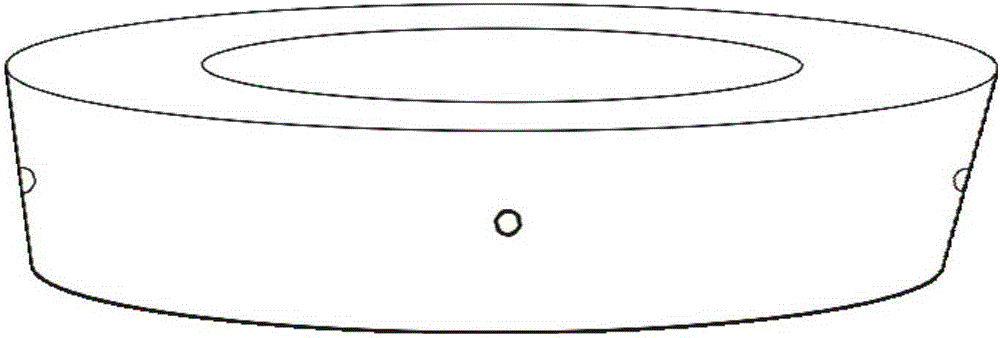

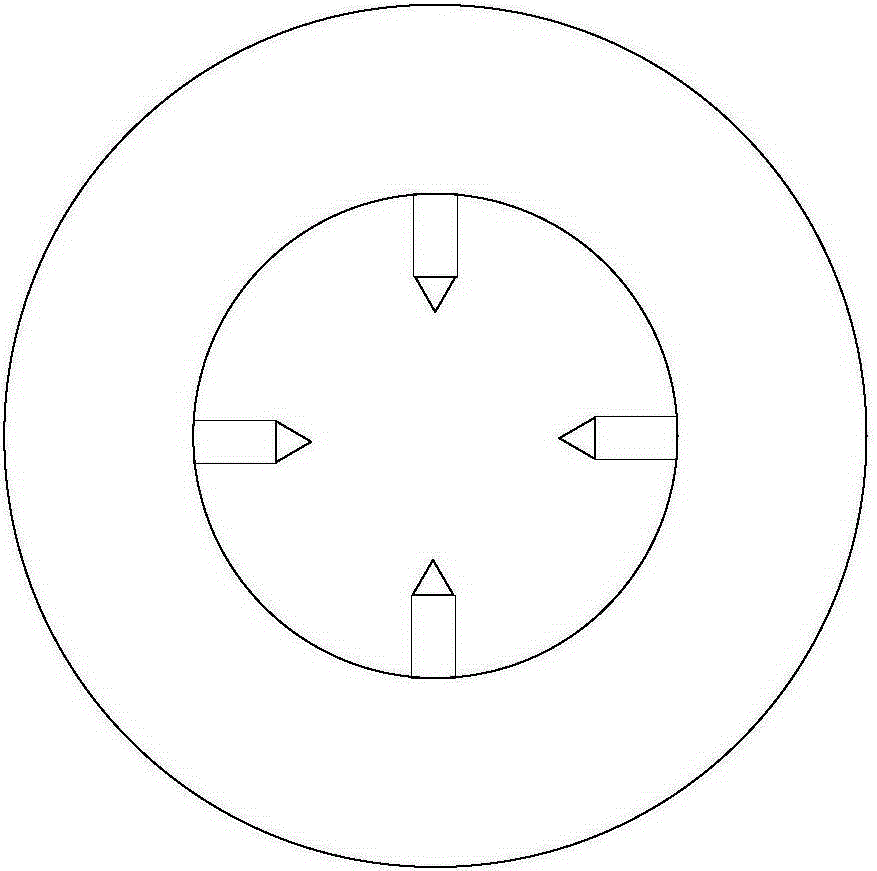

Image

Examples

preparation example Construction

[0045] The preparation method of casting type polyurethane macromolecular material of the present invention comprises the following steps:

[0046] 1) Dehydration of polymer polyol: put polymer polyol in a reactor, dehydrate at 100-130°C, vacuum degree 0.09-0.10MPa for 2-3h, take it out, and cool to 50-60°C;

[0047] 2) Preparation of prepolymer or semi-prepolymer: according to the ratio of R value 2-5 and polyisocyanate and polymer polyol functionality of 2:1 or 1:1, the mass fraction after dehydration in step 1) is Add 18.5%-35.5% melted polyisocyanate to 57%-74% polymer polyol, and react for 2.5-3.5 hours according to step 1) under vacuum conditions at 80-90°C to obtain prepolymer or semi-prepolymer Polymer, sealed and stored at room temperature, ready for use;

[0048]3) Add additives: add 0.1%-1% antibacterial agent and 0.1%-0.5% defoamer to the prepolymer or semi-prepolymer at a temperature of 50-60°C in step 2);

[0049] 4) Chain extension of the prepolymer: melt the ...

Embodiment 1

[0055] According to the R value of 2-5 and the ratio of polyisocyanate and polymer polyol functionality of 1:1, the polyether polyol polytetrahydrofuran diol with a mass fraction of 60.9% was tested at 100°C under a vacuum pressure of 0.09MPa Dehydrate for 2.5 hours, take it out, and cool to 60°C; then add 35.5% MDI, and react at 85°C for 3 hours under a vacuum of 0.09MPa to obtain a semi-prepolymer with a temperature of 85°C, which is sealed and stored at room temperature; take 0.1 % of dimethylpolysiloxane and 0.1% of titanium dioxide nano-silver antibacterial agent are added to the semi-prepolymer at a temperature of 50°C, and 3% MOCA is melted at 80°C and quickly added to the semi-prepolymer at a temperature of 50°C At the same time, add 0.4% reinforcing agent gas-phase white carbon black, stir and react for 25 minutes, inject it into the mold; vacuum dry, 100 ° C for 0.5 h of vulcanization; then heat up to 120 ° C, vacuum dry, and secondary vulcanization for 10 h, that is,...

Embodiment 2

[0057] According to the R value of 2-5 and the ratio of polyisocyanate to polymer polyol functionality of 1:1, take a mass fraction of 57% polymer polyol polypropylene glycol, and dehydrate it at 120 ° C for 2 hours under a vacuum pressure of 0.10 MPa. Take it out, cool it to 50°C; then add 35.5% MDI, and react at 80°C for 3.5 hours under a vacuum of 0.10MPa to obtain a semi-prepolymer with a temperature of 80°C, which is sealed and stored at room temperature; take 0.5% dimethylformamide Base polysiloxane and 1% β-1,4-polyglucosamine were added to the semi-prepolymer at a temperature of 50°C, and 5% ethylene glycol was melted at 80°C and quickly added to the semi-prepolymer at a temperature of 50°C. At the same time, add 1% reinforcing agent gas phase white carbon black to the prepolymer, stir and react for 35 minutes, then pour into the mold; vacuum dry, 105 ° C for 1.0 h of vulcanization; then heat up to 110 ° C, vacuum dry, and secondary vulcanization for 12 h , That is, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com