A kind of preparation method of gradient silicon carbide ceramic membrane for water purification

A technology of gradient silicon carbide and silicon carbide ceramics, which is applied in the field of material science and engineering, can solve the problems of low water flux, large discharge, and increase pollution control costs, and achieves high connected porosity and high pure water flux. , the effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

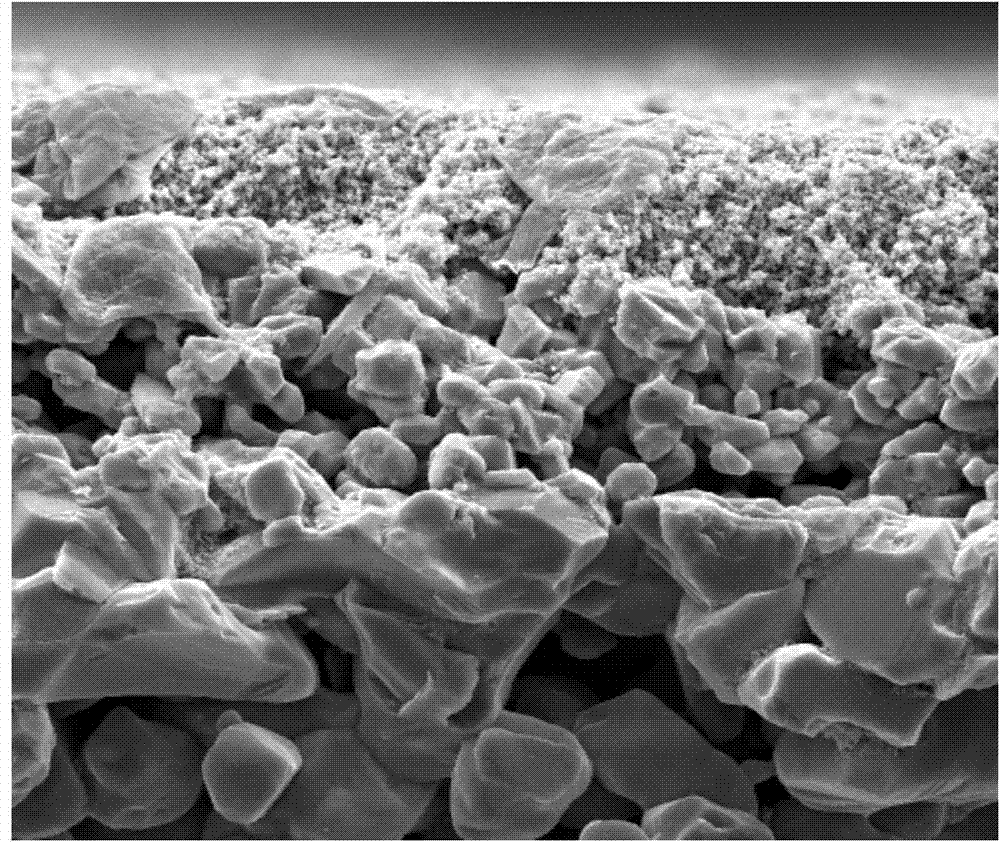

Image

Examples

Embodiment 1

[0035] 1) Preparation of silicon carbide ceramic support body

[0036] A1. Selection of raw materials: Silicon carbide powder, silicone polymer, asphalt, kerosene are selected according to the mass ratio of 100:8:7:3 for standby;

[0037] B1. Mixing of raw materials: first mix silicon carbide powder and silicone polymer to form a mixture, then mix asphalt and kerosene to form a mixture, and finally mix the obtained mixtures again;

[0038] C1. Forming of the silicon carbide ceramic support blank: put the mixture obtained in step B1 into an extrusion molding machine, and form it into a multi-channel tubular blank;

[0039] D1. Firing of silicon carbide ceramic support body: put the silicon carbide ceramic support body blank into a tube furnace, raise the temperature to 400 °C at a rate of 6 °C / min, and then increase the temperature to 1400-1400 at a rate of 9 °C / min 1500°C, keep it warm for 1h, and cool to room temperature with the furnace to prepare a silicon carbide ceramic ...

Embodiment 2

[0057] 1) Preparation of silicon carbide ceramic support body

[0058] A1. Selection of raw materials: Silicon carbide powder, silicone polymer, asphalt, kerosene are selected according to the mass ratio of 100:9:7:4 for standby;

[0059] B1. Mixing of raw materials: first mix silicon carbide powder and silicone polymer to form a mixture, then mix asphalt and kerosene to form a mixture, and finally mix the obtained mixtures again;

[0060] C1. Forming of the silicon carbide ceramic support blank: put the mixture obtained in step B1 into an extrusion molding machine, and form it into a multi-channel tubular blank;

[0061] D1. Firing of silicon carbide ceramic support body: put the silicon carbide ceramic support body blank into a tube furnace, raise the temperature to 400 °C at a rate of 6 °C / min, and then increase the temperature to 1400-1400 at a rate of 9 °C / min 1500°C, keep it warm for 1h, and cool to room temperature with the furnace to prepare a silicon carbide ceramic ...

Embodiment 3

[0078] 1) Preparation of silicon carbide ceramic support body

[0079] A1. Selection of raw materials: Silicon carbide powder, silicone polymer, asphalt and kerosene are selected according to the mass ratio of 100:10:8:4 for standby;

[0080] B1. Mixing of raw materials: first mix silicon carbide powder and silicone polymer to form a mixture, then mix asphalt and kerosene to form a mixture, and finally mix the obtained mixtures again;

[0081] C1. Forming of the silicon carbide ceramic support blank: put the mixture obtained in step B1 into an extrusion molding machine, and form it into a multi-channel tubular blank;

[0082] D1. Firing of silicon carbide ceramic support body: put the silicon carbide ceramic support body blank into a tube furnace, raise the temperature to 400 °C at a rate of 6 °C / min, and then increase the temperature to 1400-1400 at a rate of 9 °C / min 1500°C, keep it warm for 1h, and cool to room temperature with the furnace to prepare a silicon carbide cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com