Diglycolamine synthesis tower

A technology of diglycolamine and synthesis tower, which is applied in the field of diglycolamine synthesis tower, and can solve the problems of low yield, inability to use industrialized production, and many side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

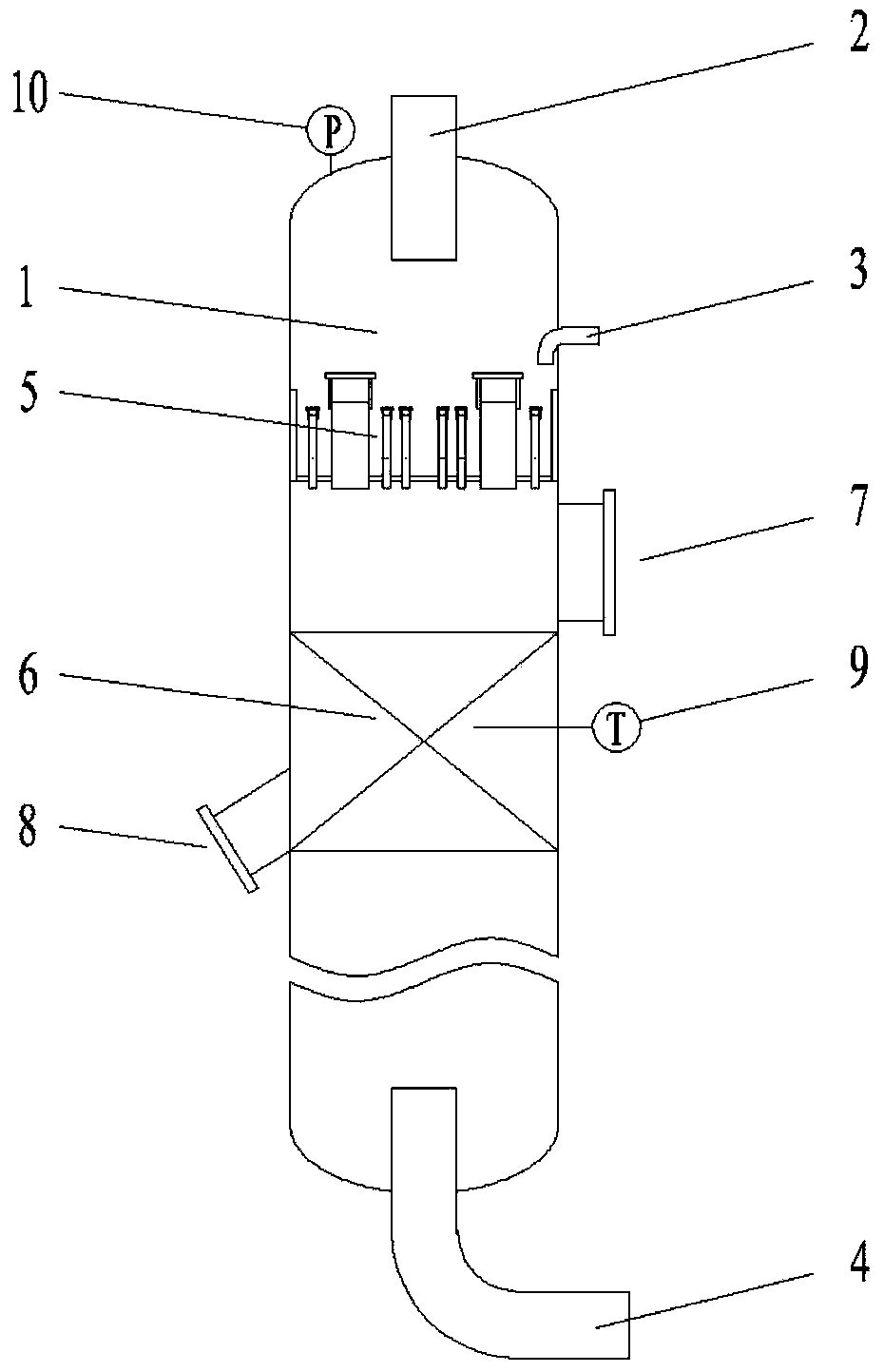

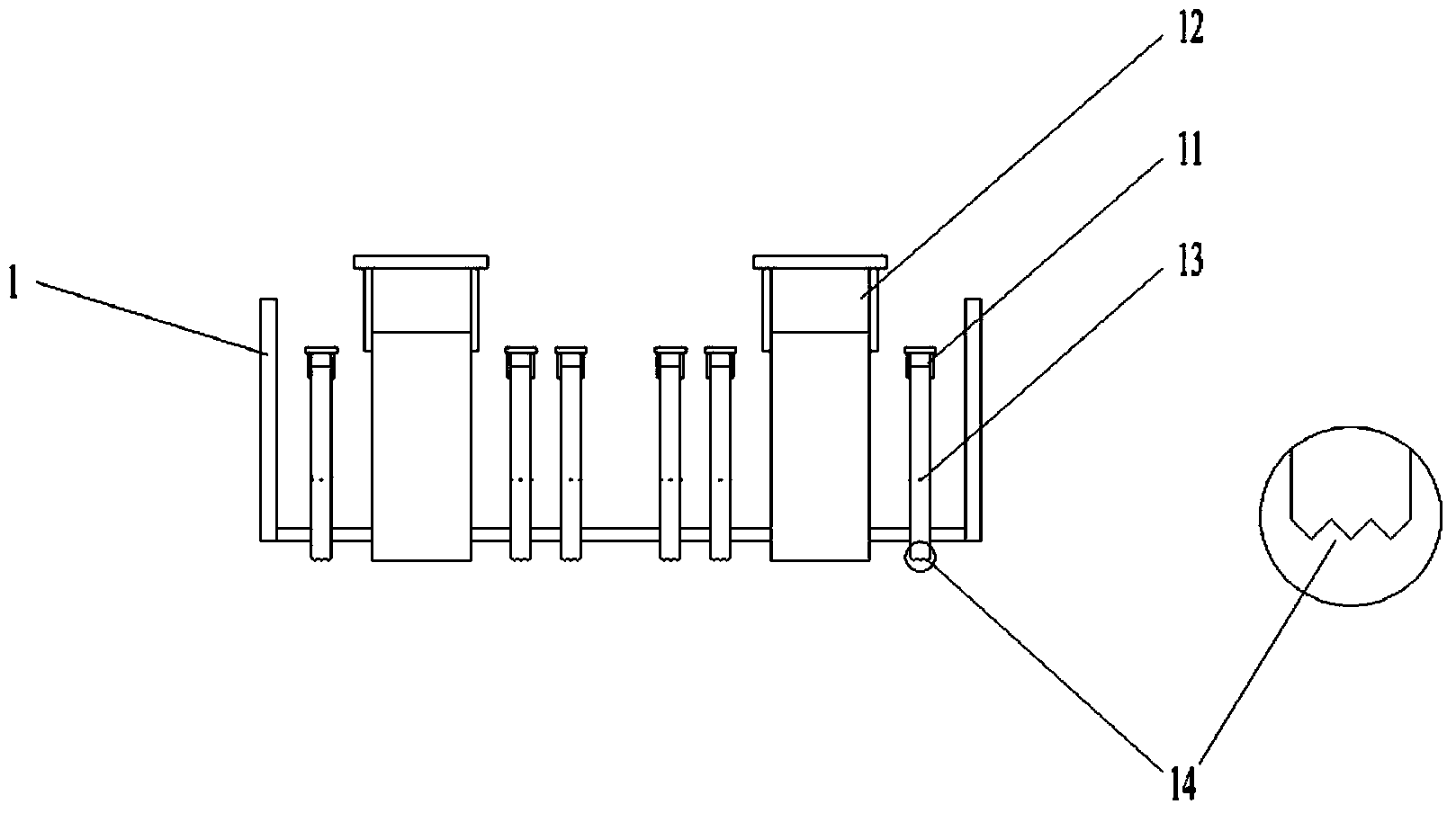

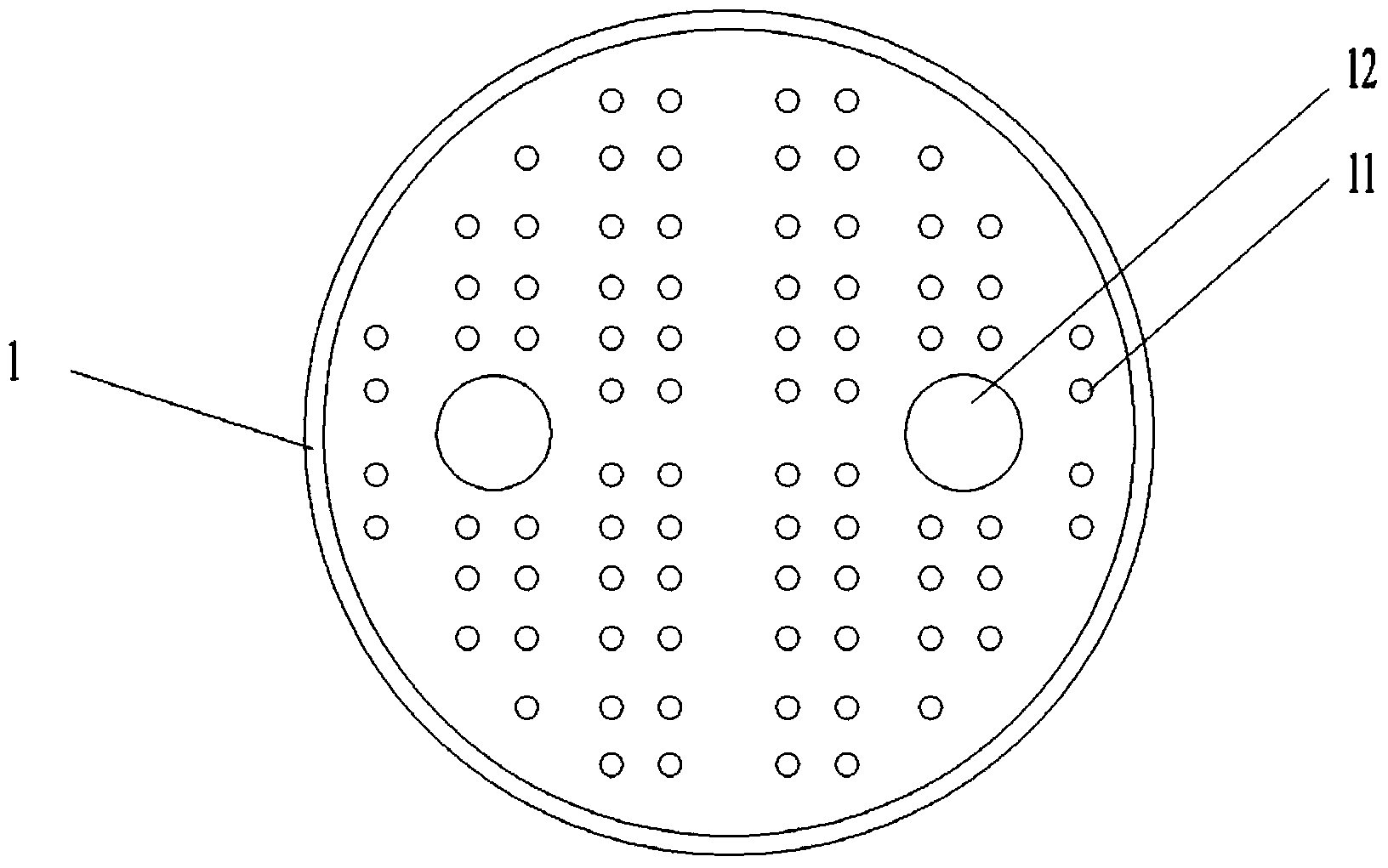

[0022] Taking four distributors 5 and four catalyst layers 6 alternately arranged and four axisymmetric overflow holes 13 on the same circumference are opened in the lower part of the drip tube 11 as an example, non-limiting embodiments are described as follows.

[0023] Fill the tower body 1 with copper-nickel catalyst from the manhole 7 and close the manhole 7 after the filling is completed.

[0024] Nitrogen is introduced into the tower body 1 from the air inlet 2 to replace the air in the tower body 1. After the replacement is completed, the preheated hydrogen is continuously introduced into the tower body 1 to raise the temperature and pressure of the tower body 1, and the hydrogen is recycled. When the catalyst temperature and the pressure in the tower rise to the reaction temperature and pressure, the circulation is stopped. The process conditions of the catalytic ammoniation reaction are: the catalyst temperature is 180-240°C and the pressure is 1.60-1.75MPa. Therefore, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com